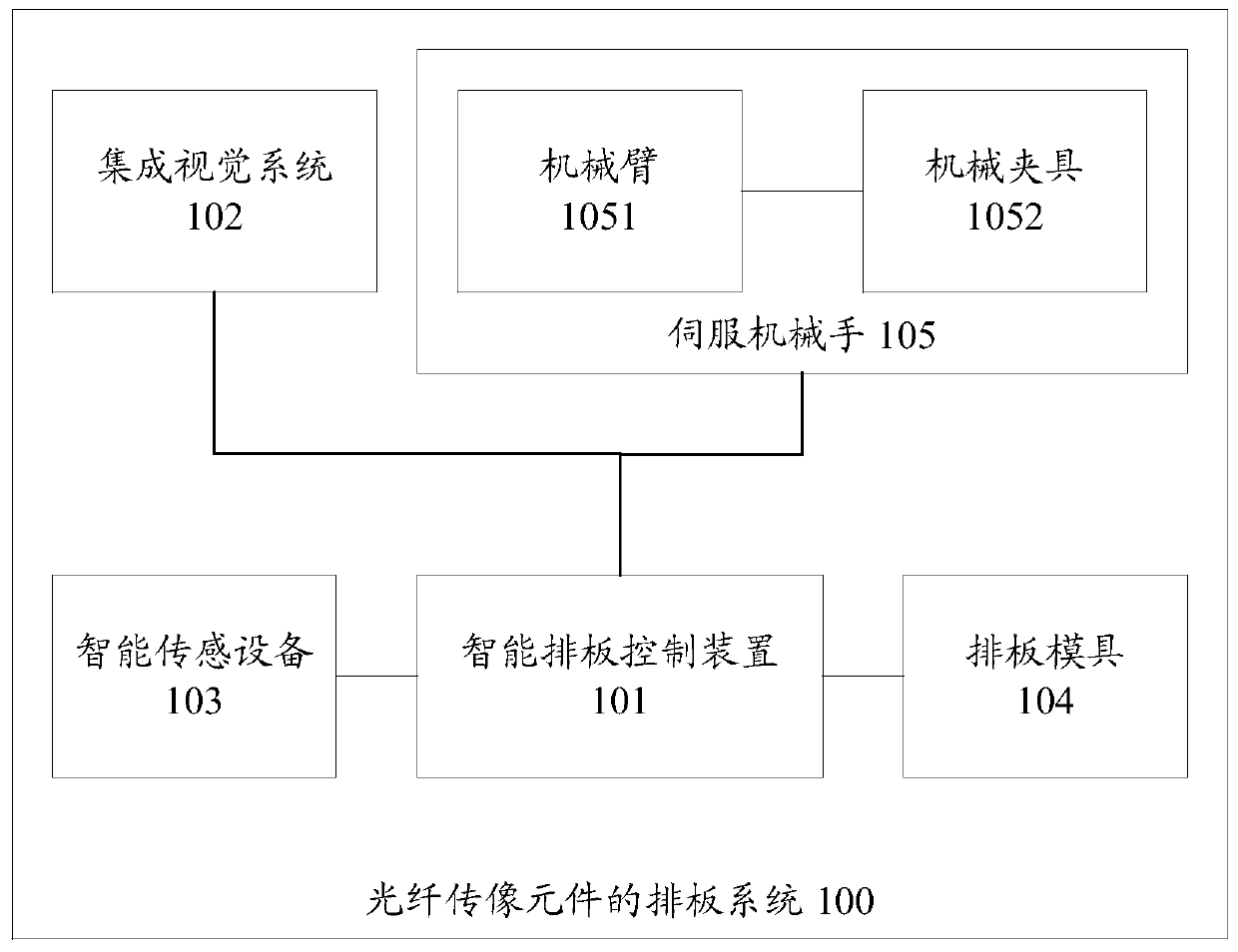

A system for arranging optical fiber imaging components

A technology of optical fiber image transmission and board arrangement, which is applied to optical components, clad optical fibers, optics, etc. Problems such as the component layout system can achieve the effect of improving labor productivity, reducing damage, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

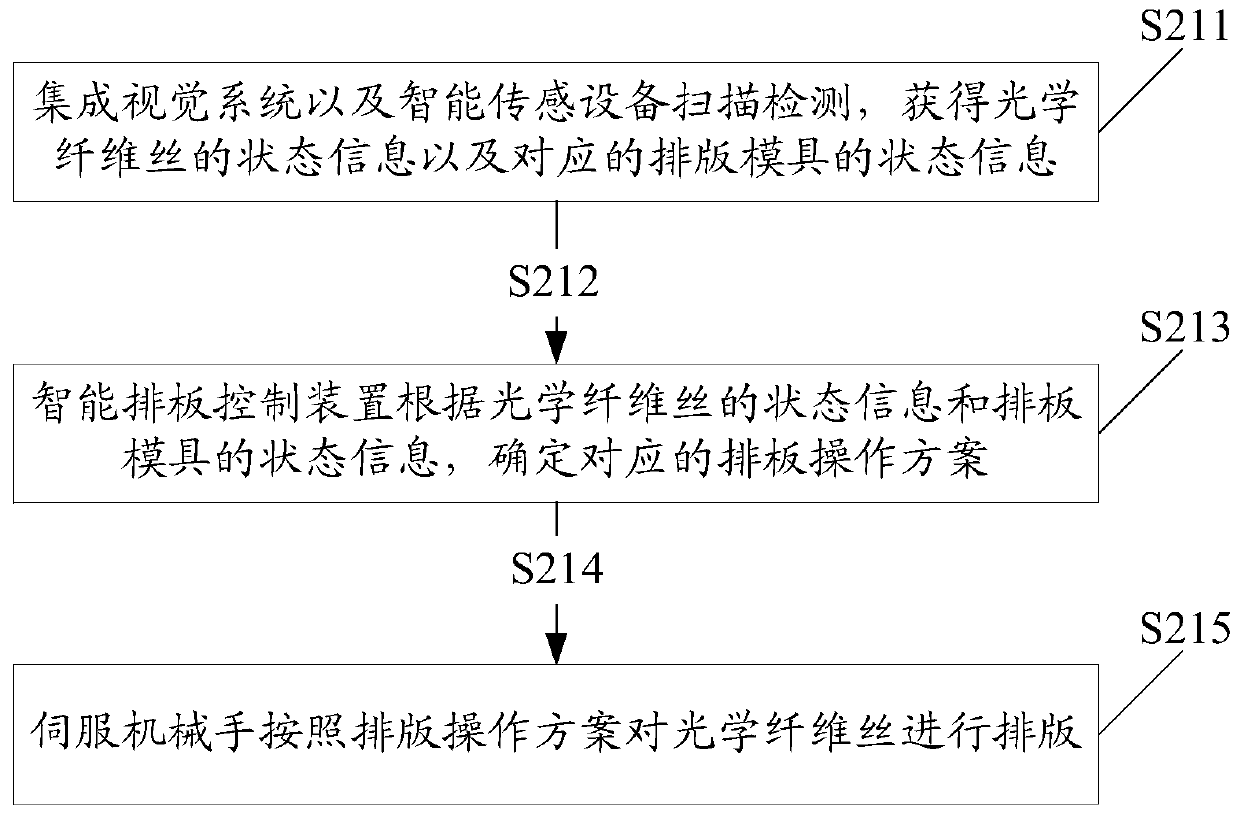

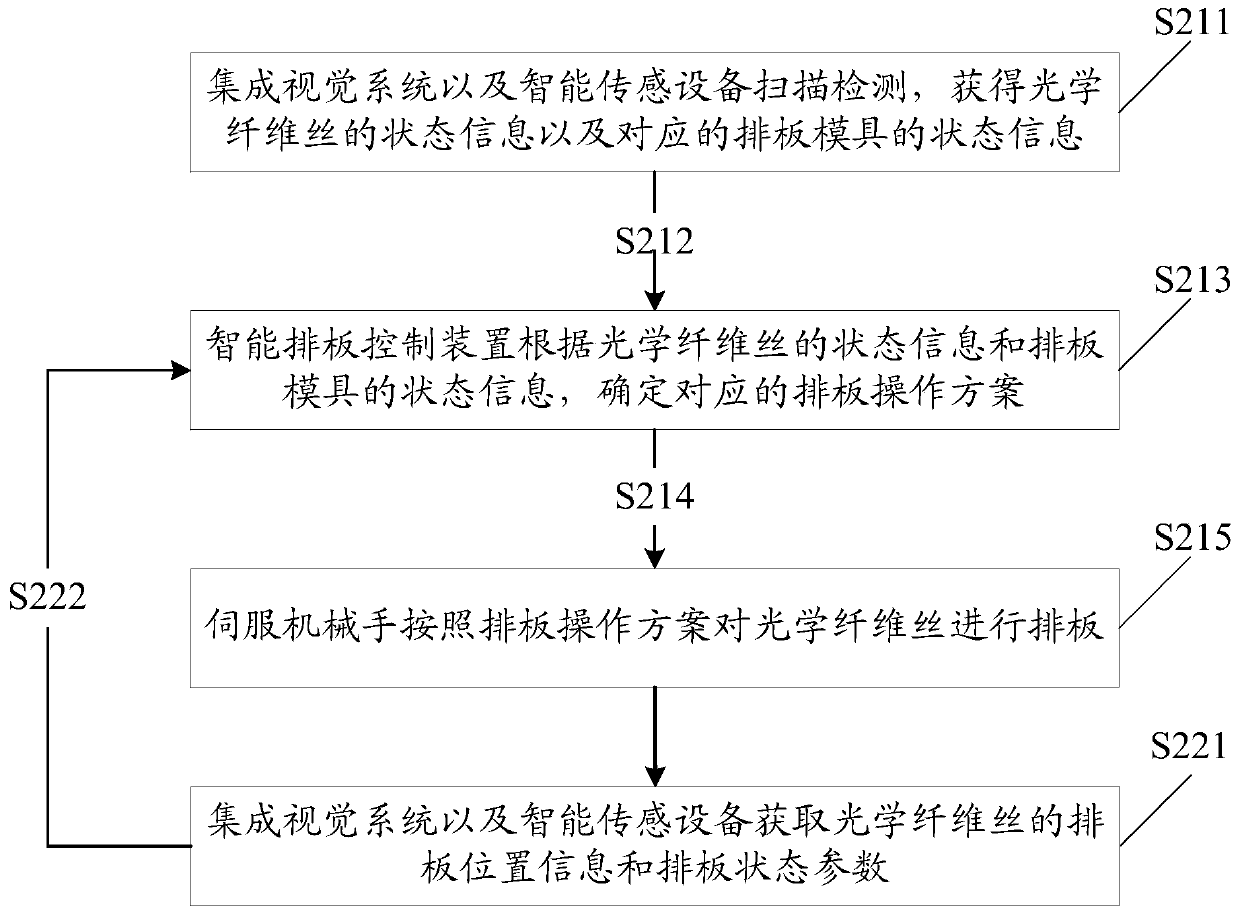

[0041] Example 1: The intelligent layout control device can pre-store the position information of the standard layout of the optical fiber filament on the preset layout mold, so that after the servo manipulator picks up the optical fiber filament, it can set the position according to the pre-stored layout, Determine the current board status of the fiber optic filament.

example 2

[0042] Example 2: The intelligent board arrangement control device pre-stores the corresponding relationship between the arranged standard optical fiber board section and the board mould, as well as the position information of each wire, so that after the optical fiber wire board is picked up by the servo manipulator, through Query the status information of the fiber optic board section, and confirm the board arrangement status of the fiber optic board section.

[0043] The above S211 to S212 are wire picking steps, the purpose of which is to pick out the unqualified optical fiber wires for size and apparent quality defects of the optical fiber wires used for board arrangement, and record the spatial position information and attribute information of these optical fiber wires . In this way, if there is a pit on the surface of a certain optical fiber filament, if it is prepared into an optical fiber image transmission component, it will seriously affect the internal quality of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com