Liquid-crystal testing system and method

A test method and test system technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of non-detachable probe test device, increase of defective rate, insufficient test capacity of liquid crystal cell, etc., to solve the problem of insufficient test capacity and improve Test efficiency and eliminate visual fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

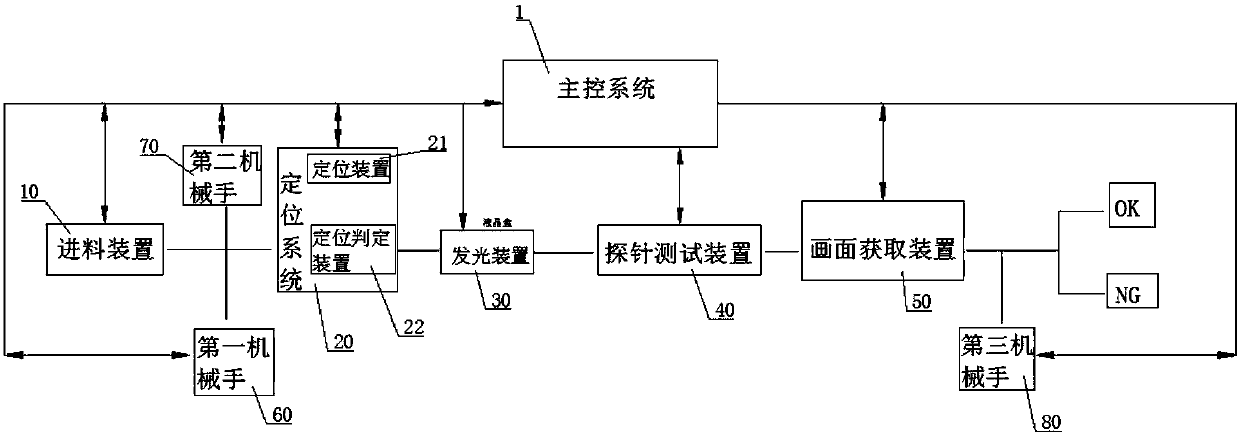

[0029] see figure 1 , the present invention provides a liquid crystal cell testing system, including a main control system 1 and a feeding device 10 connected to the main control system, a positioning system 20, a light emitting device 30, a probe testing device 40, a picture acquisition device 50, a second A manipulator 60, a second manipulator 70, and a third manipulator 80. The feeding device 10 is located on one side of the positioning system 20, and the feeding device 10 is used to place the liquid crystal cell to be tested. The feeding device 10 is provided with a lifting mechanism, and the lifting mechanism includes a pallet. Several layers of trays are placed on the tray, and the liquid crystal cells to be tested are placed on the trays. The positioning system 20 includes a positioning device 21 and a positioning determination devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com