Automatic production method and production equipment of H-shaped steel beam components

A production method and production equipment technology, applied in the field of construction steel structure and automation, can solve the problems of inability to produce H-shaped steel beams, inability to perform high-frequency welding, thick web flanges, etc., to solve aging problems and save labor Cost, the effect of increasing production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

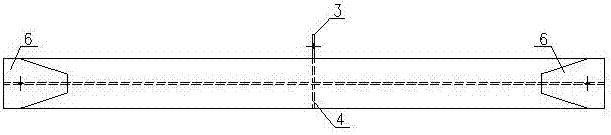

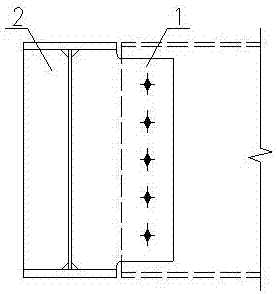

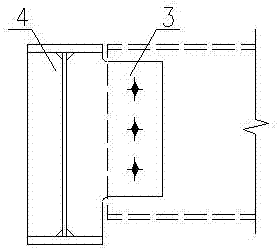

[0055] Classify the H steel beam members according to the size of the cross-section. In each type of H steel beam members, a connection plate and a stiffener with a larger cross-section are used as the reference connection plate (1) and reference stiffener (2);

[0056] When producing H-shaped steel beam members matched with the reference connecting plate (1) and the reference stiffener (2), control the positioning welding device to perform the reference connecting plate (1) or the reference connecting plate (1) in each connecting node and reference stiffener (2), to be positioned and welded;

[0057] When producing H-shaped steel beam members whose cross-section does not match the reference connecting plate (1) and reference stiffener (2), control the cutting device to check the reference connecting plate (1), or the reference connecting plate (1) and reference stiffening plate ( 2), cut to obtain the connecting plate (3) and stiffener (4) matching the H-shaped steel beam mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com