Preparation method for PDMS variable period annular microfold structure

A variable period and wrinkle technology, which is applied in the field of preparation of PDMS variable period annular micro-wrinkle structures, can solve the problems of difficult to control the regularity and ordering of surface wrinkles, and achieves short cycle, low production cost and simple process flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and implementation.

[0023] A method for preparing a PDMS variable-period annular micro-fold structure, the steps are as follows:

[0024] (1) Preparation of PDMS soft film. Mix the PDMS prepolymer and curing agent at a ratio of 10:1, stir evenly, place in a vacuum drying oven, and keep vacuuming until the liquid has no bubbles. Then pour the vacuumed PDMS liquid on the surface of the glass substrate, heat and solidify at 100°C for 2 hours, and then cool it down. After cooling, the PDMS was peeled off from the glass substrate, and then cut into circular PDMS for later use.

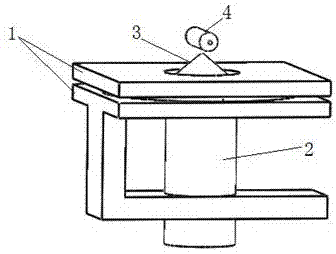

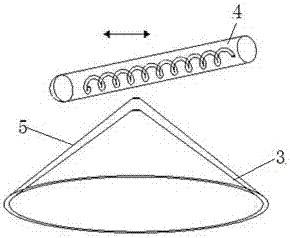

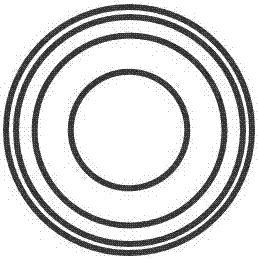

[0025] (2) The fabricated circular PDMS membrane is stretched. Fix the circular PDMS membrane in a fixture with a circular hole 1 ( figure 1 ), and then push the circular PDMS membrane 3 from the hole to form a cone-shaped structure with a pre-specified angle cone top 2 .

[0026] (3) Treat the taper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com