Special-shaped steel bar, steel bar truss and floor slab hanging mould method system unit

A technology of steel bar trusses and steel bars is applied to the field of steel bars used as upper and lower chord bars of steel bar trusses. Easy, shorten the construction period, and ensure the effect of bearing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0133] In order to help your examiner to understand the technical means and technical features used to achieve the purpose of the present invention, as well as the effects that can be achieved by implementing it in the industry, we only express and describe it in detail in the form of embodiments with schematic drawings. Description, and the accompanying drawings used therein are only for illustration and supplementary description purposes, not the actual proportion, number and configuration of steel bars after the actual implementation of the present invention, which will be described in advance.

[0134] For ease of understanding, elements of the same type in the description of the following embodiments are described with the same symbols.

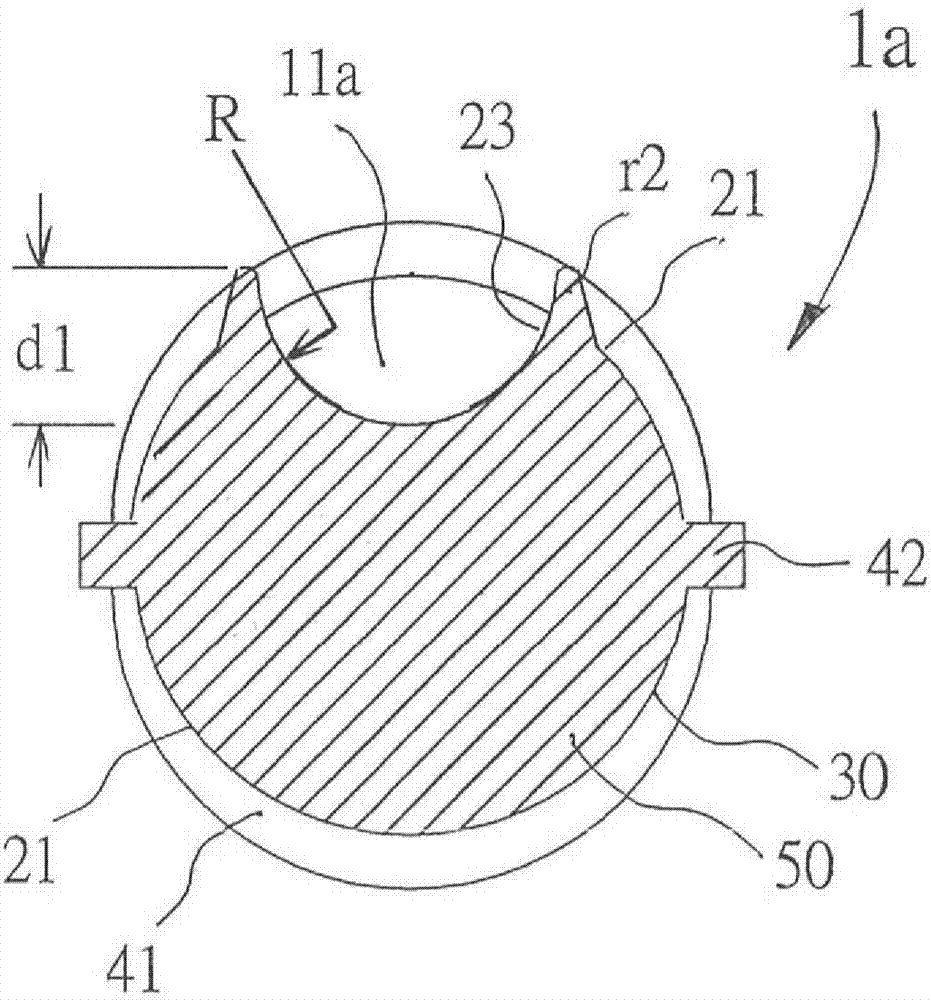

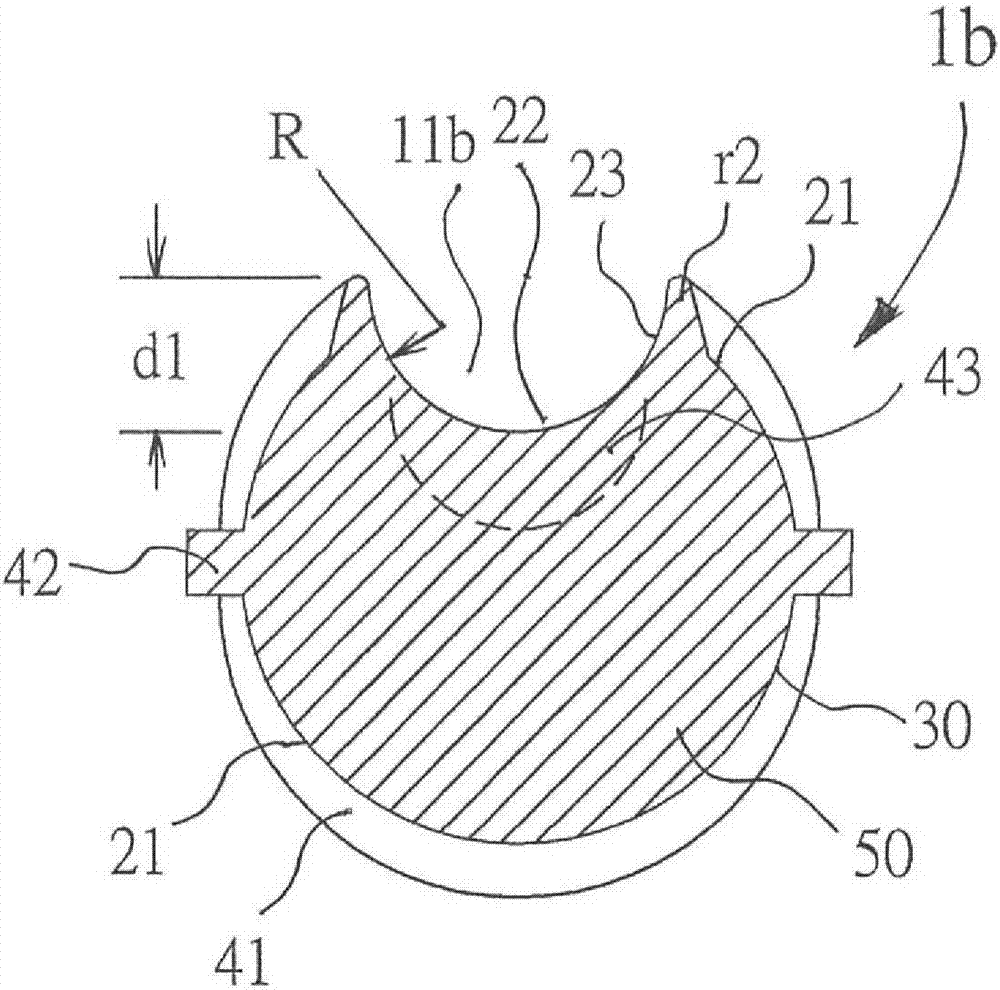

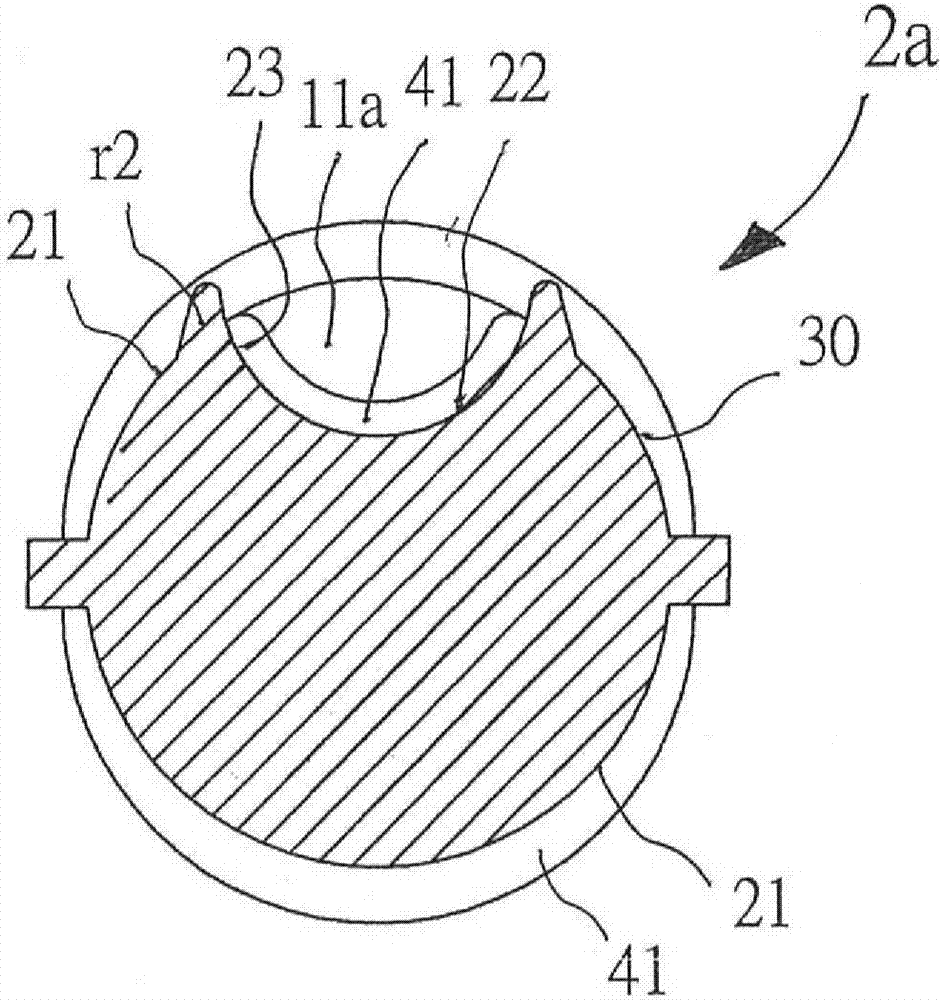

[0135] refer to Figure 6B and Figure 6A , which is a schematic diagram of an embodiment of the special-shaped steel bar of the present invention. in, Figure 6B As shown, with hot rolling and rolling technology, the embodiment of sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com