fly-back AC-AC converter static var compensator

A static var compensation and flyback technology, applied in reactive power adjustment/elimination/compensation, AC power input conversion to AC power output, AC network circuits, etc., can solve weak voltage matching, increase device size, Poor reliability of STATCOM devices and other issues, to achieve the effect of reducing the number of inductors and transformer windings, easy modular manufacturing, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

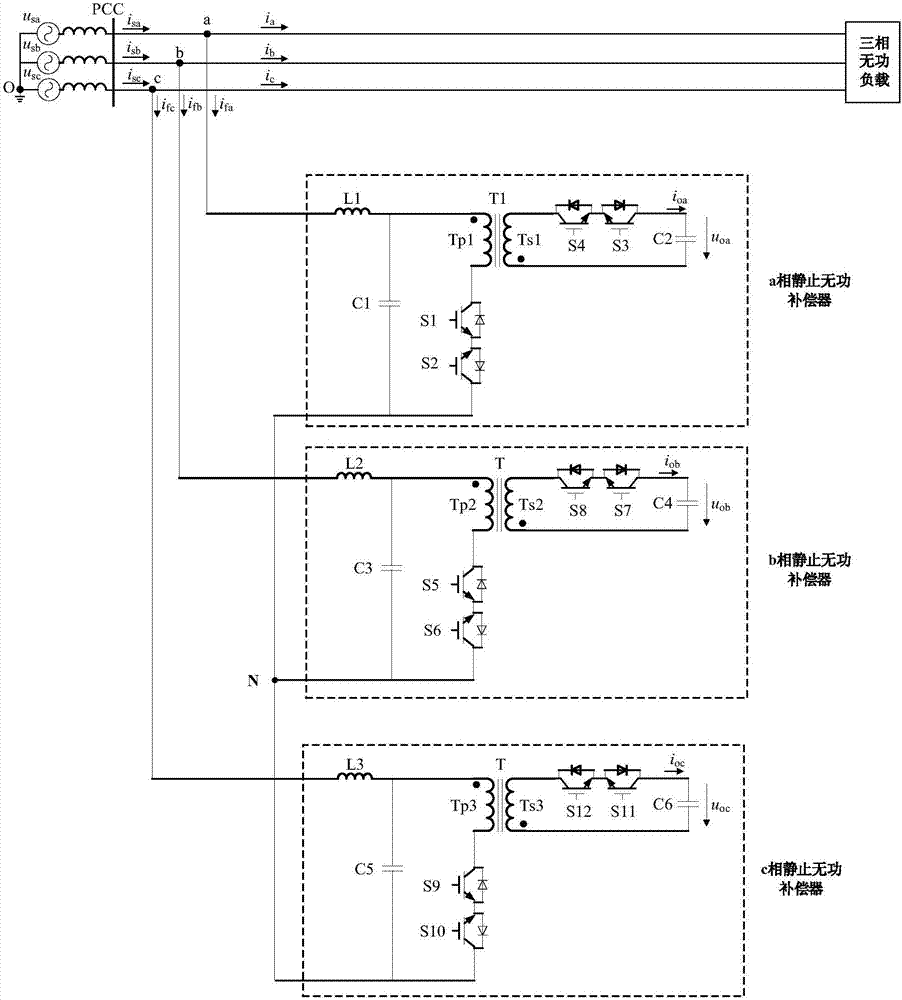

[0044] combine figure 1 As shown, a static var compensator based on a flyback AC-AC converter includes a three-phase static var compensator main power circuit, wherein each single-phase static var compensator main power circuit includes sequentially connected input filter, flyback AC-AC conversion unit and reactive power compensation capacitor. The main power circuit of the three-phase static var compensator includes the main power circuit of the a-phase static var compensator, the main power circuit of the b-phase static var compensator and the main power circuit of the c-phase static var compensator, and the main power circuit of the a-phase static var compensator One end of the main power circuit of the power compensator is connected to the transmission line between the grid side of phase a and the reactive load of phase a, and one end of the main power circuit of the static var compensator of phase b is connected to the grid side of phase b and the reactive load of phase b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com