Novel multi-motor axis alignment detection device of numerical control machine tool

A CNC machine tool and axis alignment technology, which is applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of long time consumption, complicated operation, and high skill requirements of operators, and achieve the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and examples of implementation.

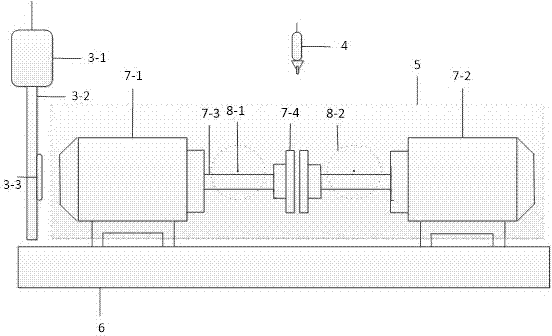

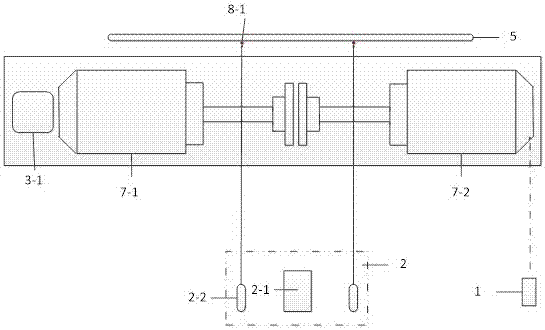

[0016] Use the motor coupling (7-4) to connect the two tested motors and place them on the conveyor belt (6).

[0017] The ultrasonic transmitter (1) continuously sends detection sound waves. When the measured object on the conveyor belt (6) enters the preset range, the ultrasonic module will feed back the "discovery" signal of the measured object to the fence controller (3 -1), then the fence controller (3-1) extends the control fence (3-2).

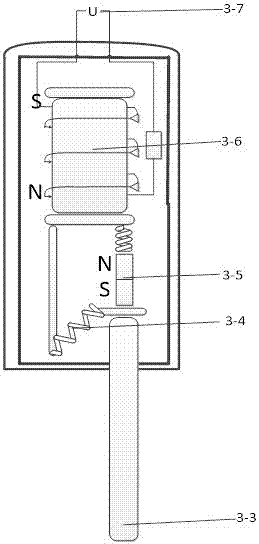

[0018] The fence controller (3-1) sends out a signal to energize the power supply (3-7) of the fence device (3), and under the action of the coil (3-6), a magnetic field is generated around, and the magnetic poles of the same name repel each other, and the magnetic force will The bar magnet (3-5) is repelled downward by the spring, and then the stretchable intelligent fence (3-2) is pulled downw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com