Hot-melting welding device of plastic composite pipe of steel wire framework

A hot-melt welding, steel wire skeleton technology, applied in the direction of tubular items, other household appliances, household appliances, etc., can solve the problems of asymmetric axial pressure, slow progress, uneven heating, etc., to save time, tight contact, Economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

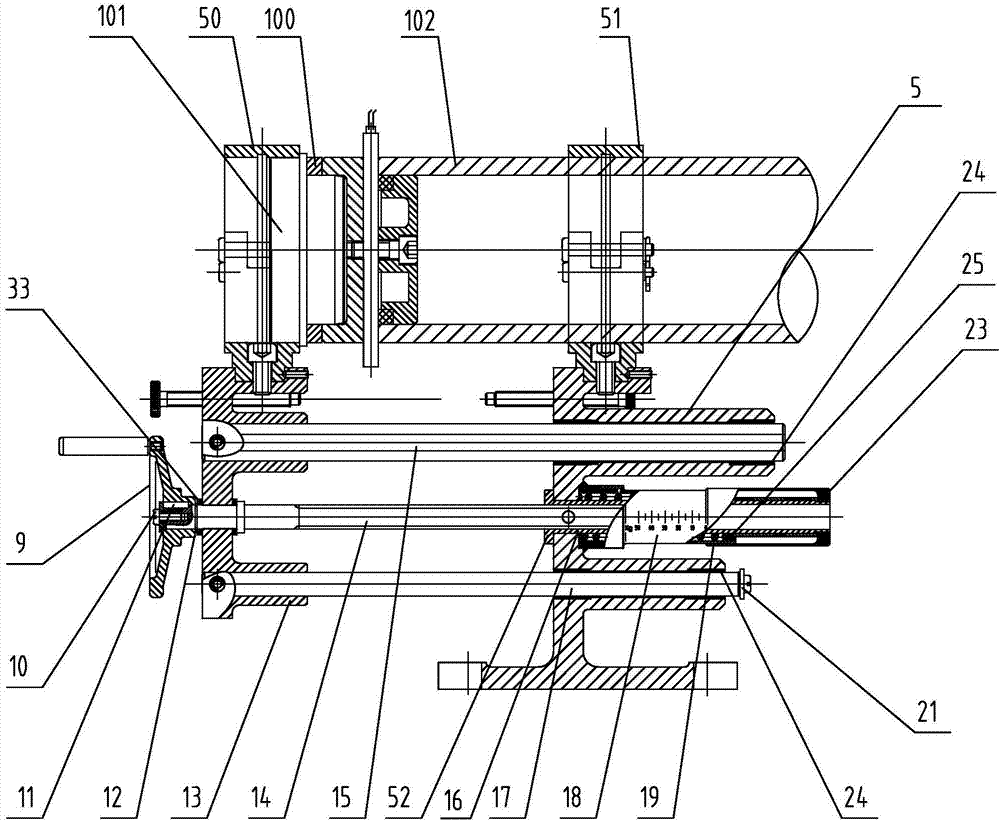

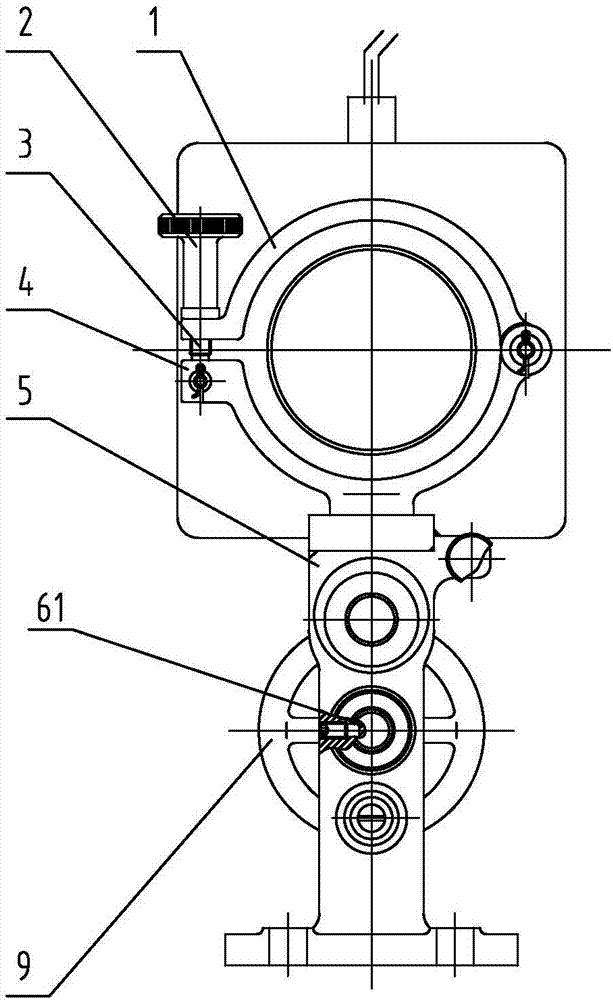

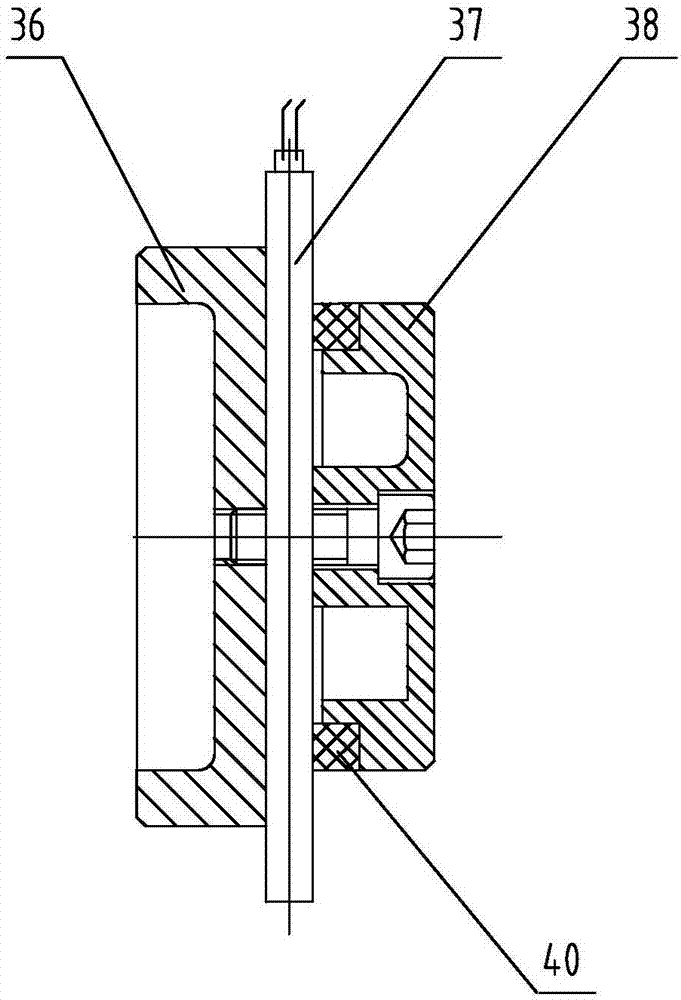

[0021] Specific implementation mode one: combine Figure 1 to Figure 4 Description of this embodiment, a steel wire skeleton plastic composite pipe hot-melt welding device, which includes a moving assembly, a clamping assembly and a heating device, the moving assembly includes a guide body 5, a moving body 13, a handle 9, a screw sleeve 16, a scale The pipe 18, the pipe cover 23, the lead screw 14 and two guide rods arranged horizontally respectively, the guide body 5 and the moving body 13 are arranged vertically and juxtaposed from left to right, wherein the lower part of the guide body 5 is horizontally fixed on the working table , the screw sleeve 16 is mounted on the guide body 5, and the screw sleeve 16 is limited in the circumferential direction by the screw fixed on the guide body 5. The screw 14 is worn on the moving body 13 and the screw sleeve in turn from left to right. 16, threaded connection between the screw sleeve 16 and the lead screw 14, the lead screw 14 is ...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the screw sleeve 16 is in clearance fit with the guide body 5 , and the left end of the screw sleeve 16 is fixedly connected to the limiting ring 52 . Designed in this way, the clearance fit between the screw sleeve 16 and the guide body 5 facilitates the movement of the screw sleeve 16 in the guide body 5, and the limit ring 52 limits the limit displacement of the screw sleeve 16 to the right, preventing the screw sleeve 16 from moving due to the action of the spring 19. Detach guide body 5. Other compositions and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0029] Specific implementation mode three: combination figure 1 , 2Describe this embodiment, two guide rods are first guide rod 15 and second guide rod 17 respectively, and first guide rod 15 is positioned at the top of lead screw 14, and second guide rod 17 is positioned at the bottom of lead screw 14, two guide rods The left ends of the rods are respectively worn on the mobile body 13 and are fixedly connected with the mobile body 13 . In such a design, the guide rod will guide the moving body 13, and at the same time support the moving part and the mold 101. Therefore, the left end of the guide rod is installed in the moving body 13 to increase the distance between the guide rod and the moving body 13. connection stability, even if the connection between the guide rod and the moving body 13 is stronger. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com