Condenser of distillation wine brewing apparatus

A technology for condensers and equipment, applied in the field of distillation and brewing equipment, can solve the problems of complex structure of condensers and inconvenient assembly, and achieve the effects of omitting the sealing process, improving the cooling effect, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

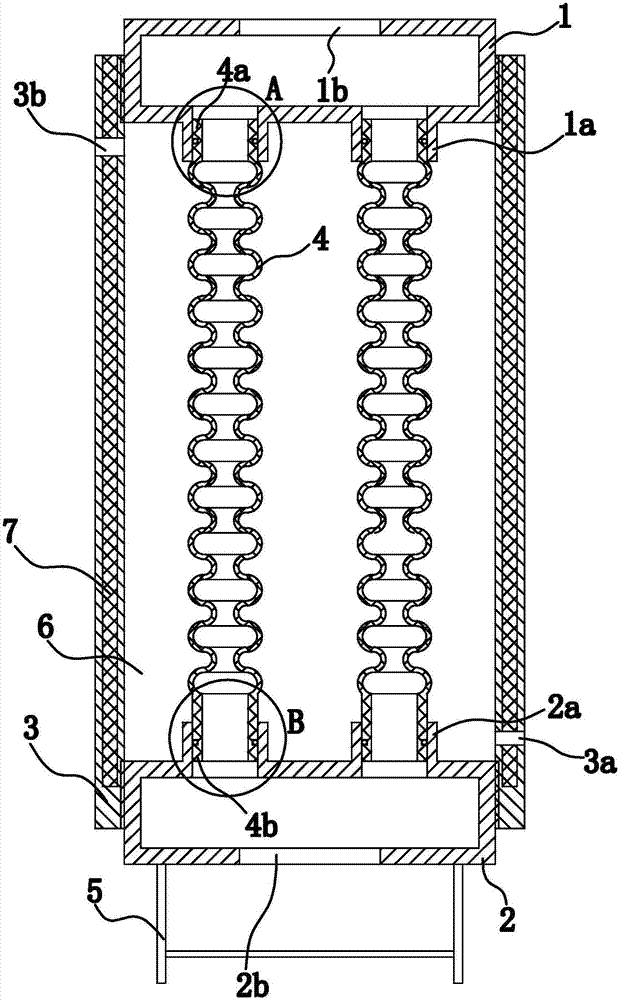

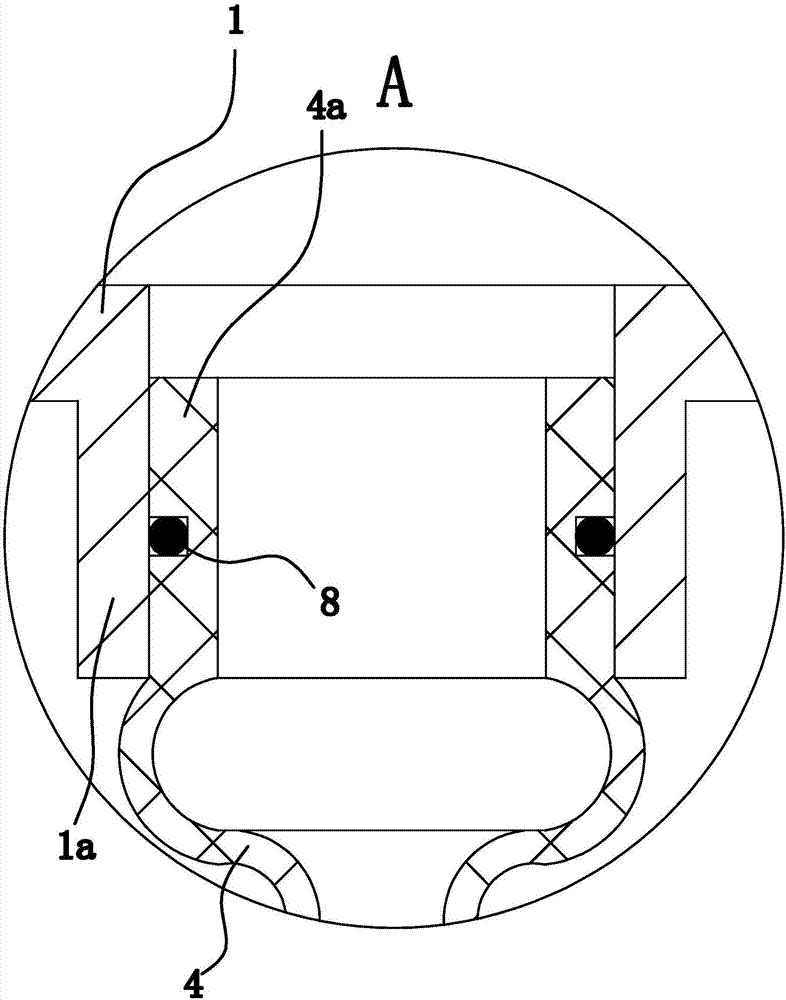

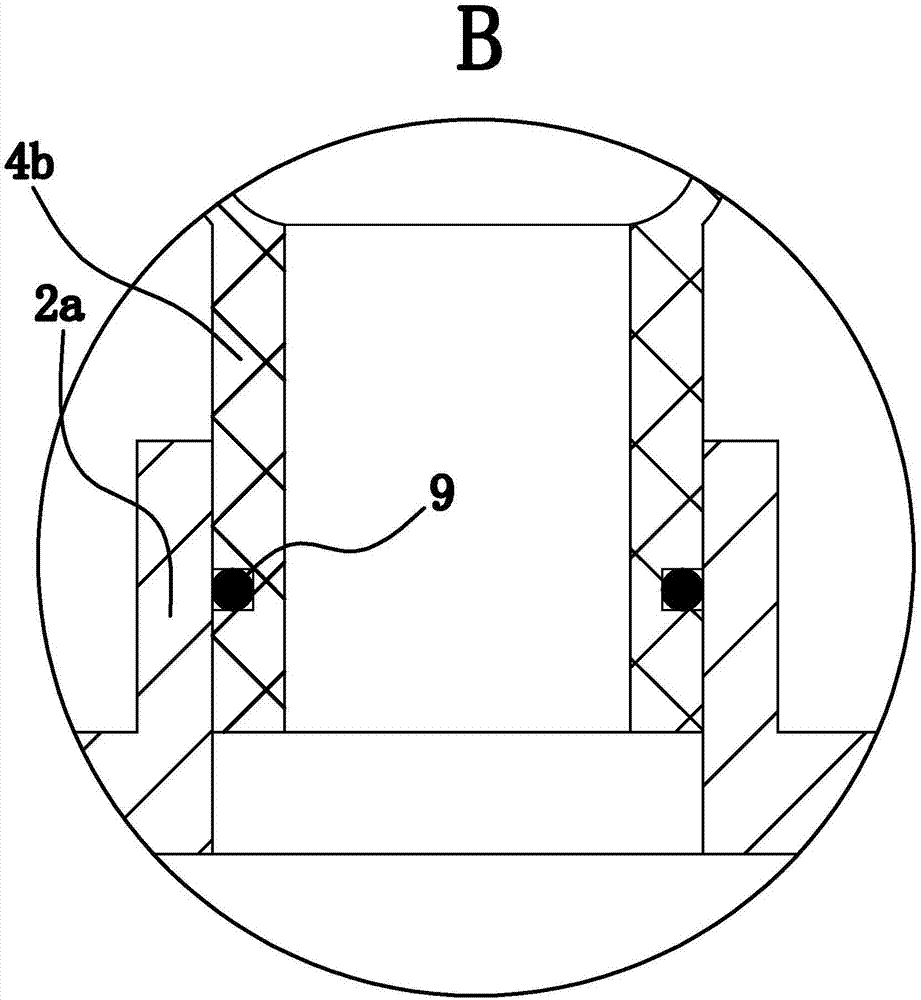

[0029] Such as figure 1 As shown, the condenser of the distilling and brewing equipment is composed of an upper casing 1, a lower casing 2, a connecting cylinder 3, a bellows 4, and the like. Wherein, the corrugated pipe 4 is made of heat-conducting material, and the heat-conducting material can be brass, stainless steel and the like. The upper box body 1, the lower box body 2 and the connecting cylinder 3 are all made of brass material.

[0030] Specifically, the upper box body 1 is located above the lower box body 2, and the two positions are facing each other. Both the upper box 1 and the lower box 2 have closed inner cavities, and the outer surfaces of the upper box 1 and the lower box 2 are cylindrical. In this embodiment, both the upper box body 1 and the lower box body 2 are composed of a plurality of boards. A bracket 5 is installed at the bottom of the lower box body 2 for supporting the entire condenser.

[0031] Such as figure 1 As shown, the connecting cylinde...

Embodiment 2

[0037] The structure and principle of this second embodiment are basically the same as that of the first embodiment, except that the upper box body 1 and the lower box body 2 are fixed to the connecting cylinder 3 by welding, and the connection between the upper box body 1 and the connecting cylinder 3 A seal ring 1 is provided between the two to connect and seal, and a seal ring 2 to connect and seal the two is provided between the lower box body 2 and the connecting cylinder 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com