Determination method of anti-pull strength resistance of embedded parts in railway fastening system

A railway fastener and pullout strength technology, which is applied in the field of determining the pullout strength resistance of embedded parts in the railway fastener system, can solve the problems of damage to nylon sleeves and sleepers, increase the workload of track maintenance, and achieve safety assurance , prolong life, and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The first embodiment mainly illustrates the method for determining the pullout strength and resistance of PANDROL pre-embedded iron seat type boltless fasteners.

[0030] (1) Stress analysis on the spring bar:

[0031] Pandrol fast clip fastening system Each set of fastenings consists of two clips that are fastened on both sides of the rail foot respectively, and the fastening force of each clip is marked as F c , then the vertical restraint resistance F of the fastener system x is the buckle pressure F of a single clip c 2 times of , namely:

[0032] f x = 2F c (1)

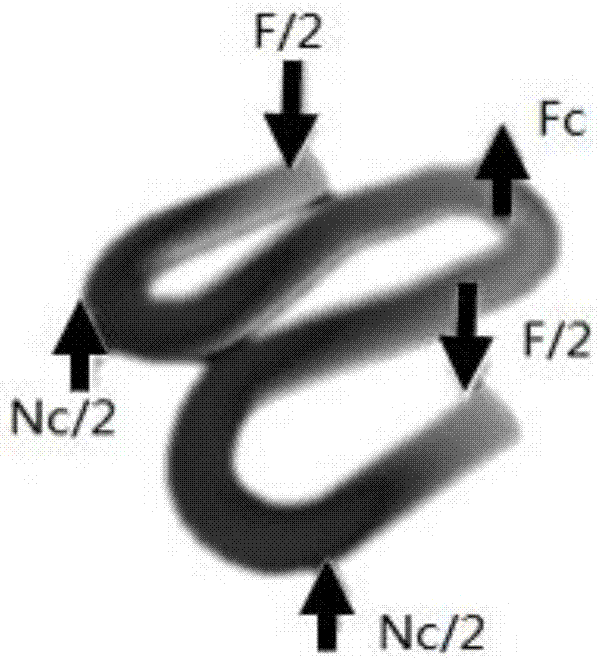

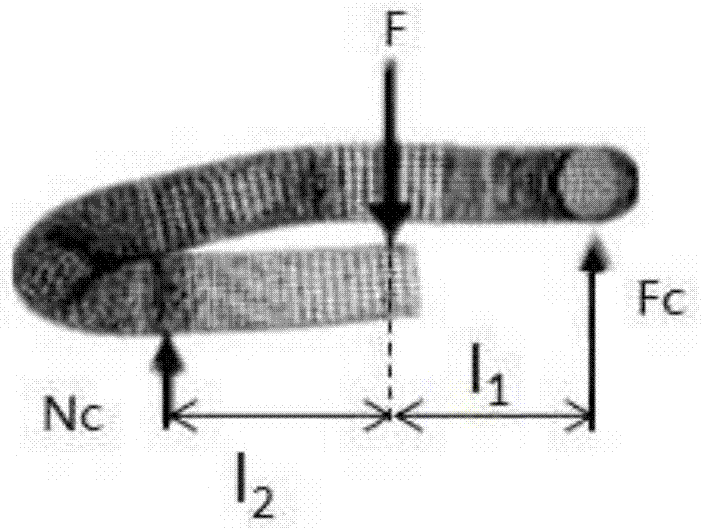

[0033] The force of the spring bar is as figure 1 and figure 2 As shown, the buckle point of the elastic strip is subjected to the upward force and the buckle force is F c The size is equal and the direction is opposite, and the heel of the elastic bar is supported by the elastic bar seat N c / 2, the restraining force of the outer branch of the spring bar F / 2, F in the state of force balance c ...

Embodiment 2

[0057] The second embodiment is a method for determining the pullout strength and resistance of Vossloh bolt fasteners.

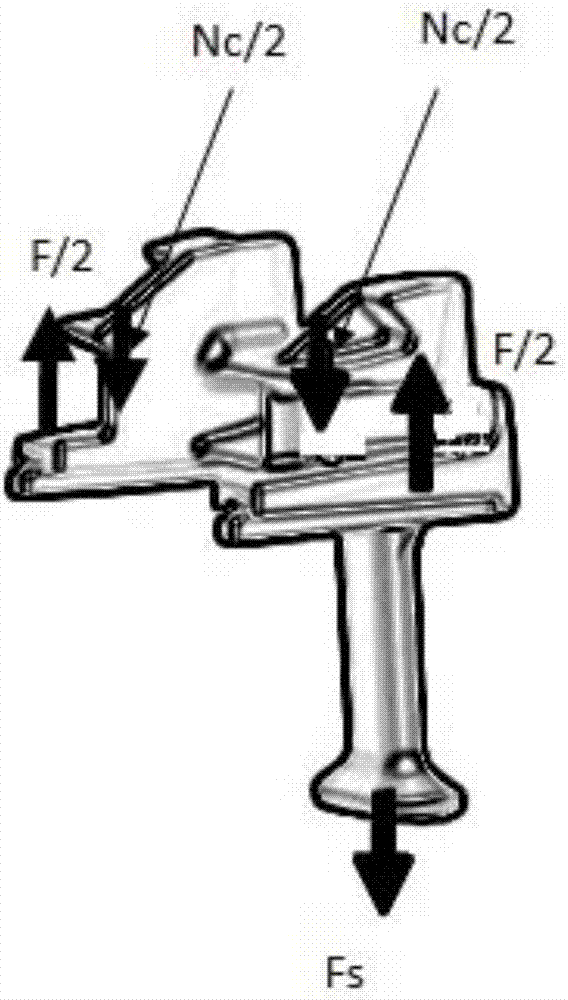

[0058] The same as the method for stress analysis of a pair of fasteners in the embodiment, the fastening pressure of each elastic strip on both sides of the rail foot is F c , the force of the spring bar is as Figure 5 As shown, the buckle point of the elastic strip is subjected to the upward force and the buckle force is F c The size is equal and the direction is opposite, and the heel of the elastic bar is supported by the elastic bar seat N c / 2, the binding force of the outer branch of the spring bar F / 2, the pulling force of each embedded casing F s / 2, F in the state of force balance c , N c and the relation of F is:

[0059] f c +N c =F b (8)

[0060] f c ·s 1 =N c ·s 2 (9)

[0061] N c – The total bearing force of the heel of the elastic seat elastic;

[0062] f b – clamping force of clip bolts;

[0063] the s 1 – the lateral ...

Embodiment 3

[0077] 1) The method for determining the pullout strength and resistance of the embedded part of the bottom plate fastener in the third embodiment.

[0078] Since the bottom plate rigidly connects the crimping system on both sides of the rail, it effectively balances the crimping pressure and various restraint resistances, such as the crimping force of the spring bar and the reaction force from the cushion under the rail to the rail surface; the supporting force of the spring bar base and the elastic bar limit constraints, etc. The pullout strength resistance of the bottom plate fastener is usually connected in series by two parts, the elastic strip system and the anchor bolt system. The design of the anchor bolt system needs to ensure the constraints and strength requirements of the fastener system with six degrees of freedom in three directions. In order to ensure that the vertical resistance is usually not less than the buckle pressure of the elastic strip, the pretightenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com