Colorful-patterned soft porcelain decoration panel and preparation method thereof

A decorative panel and pattern technology, applied in the field of building decorative materials, can solve the problems of large amount of pigment used, lower production cost, dull color, etc., and achieve the effect of low production cost, long service life and brilliant color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

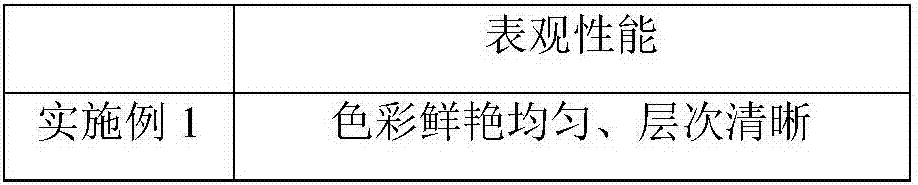

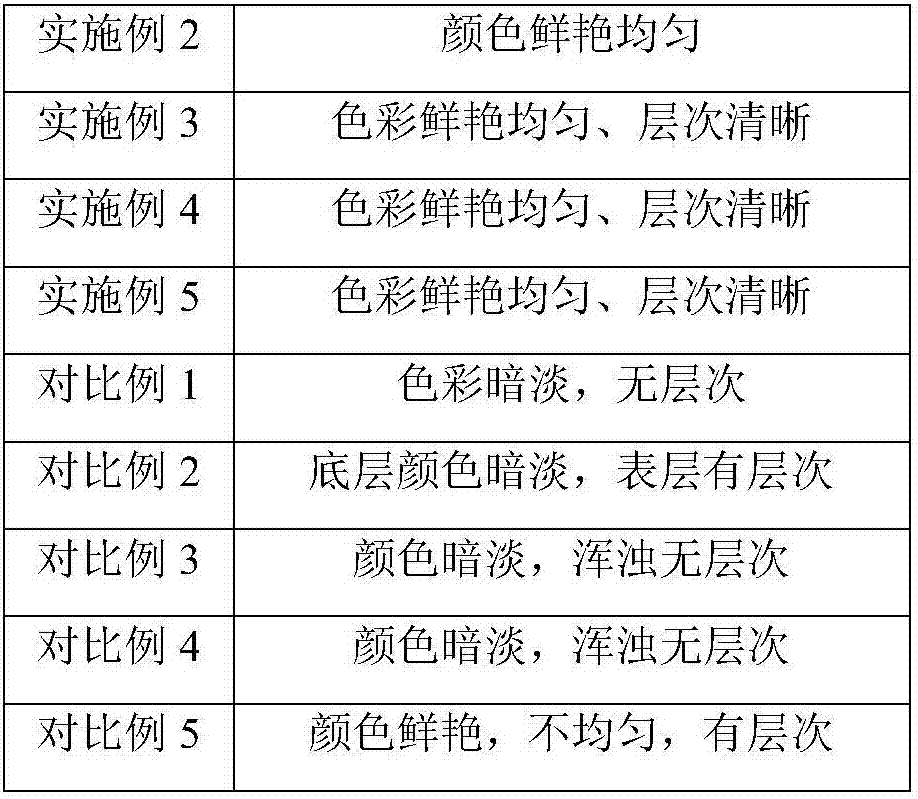

Examples

Embodiment 1

[0030] A method for preparing a soft porcelain decorative panel with colorful patterns, characterized in that:

[0031] Step (1) Preparation of surface color paste: take coupling agent 3, 10 parts of silicon acrylic emulsion, and inorganic pigment 2 and put them into a blender and stir to form silicon acrylic emulsion color paste. The pigments are iron oxide red, iron oxide yellow and titanium white respectively, and three color pastes of red, yellow and white are obtained, and the color pastes are stored separately;

[0032] Step (2) Prepare the bottom layer powder: take 15 parts of cement, 20 parts of quartz sand, 5 parts of phenolic resin, and 2 parts of coupling agent and add them into a kneader and mix evenly to obtain the bottom layer powder;

[0033] Step (3) preparing the mixed material: adding the second mixed powder obtained in step (2) to 15 parts of silicon acrylic emulsion, and stirring to obtain the second bottom mixed material;

[0034] Step (4) making molds, p...

Embodiment 2

[0038] A method for preparing a colorful porcelain decorative material, characterized in that:

[0039] Step (1) Preparation of surface color paste: take coupling agent 3, 10 parts of silicon acrylic emulsion, and inorganic pigment 2 and put them into a blender and stir to form silicon acrylic emulsion color paste. The pigments are iron oxide red, and the color paste is stored separately;

[0040] Step (2) preparation of bottom powder: take 15 parts of cement, 20 parts of quartz sand, 5 parts of phenolic resin, and 2 parts of coupling agent and add them into a kneader and mix evenly to obtain the bottom powder;

[0041] Step (3) preparing the mixed material: adding the second mixed powder obtained in step (2) to 15 parts of silicon acrylic emulsion, and stirring to obtain the second bottom mixed material;

[0042] Step (4) making molds, pouring the bottom layer mixture into the mold, pressing the mold, and pre-drying for 3 minutes;

[0043] Step (5) preparation of colorful s...

Embodiment 3

[0046] A method for preparing a soft porcelain decorative panel with colorful patterns, characterized in that:

[0047] Step (1) Preparation of surface color paste: take coupling agent 3, 10 parts of silicon acrylic emulsion, and inorganic pigment 2 and put them into a blender and stir to form silicon acrylic emulsion color paste. The pigments are iron oxide red, iron oxide yellow, and carbon black respectively, and three color pastes of red, yellow and black are obtained, and the color pastes are stored separately;

[0048] Step (2) preparation of bottom powder: take 15 parts of cement, 20 parts of quartz sand, 5 parts of phenolic resin, and 2 parts of coupling agent and add them into a kneader and mix evenly to obtain the bottom powder;

[0049] Step (3) preparing the mixed material: adding the second mixed powder obtained in step (2) to 15 parts of silicon acrylic emulsion, and stirring to obtain the second bottom mixed material;

[0050] Step (4) making molds, pouring the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com