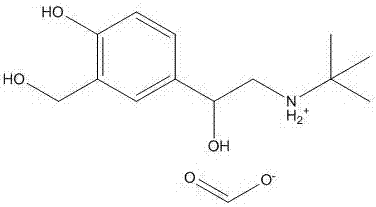

Novel salbutamol drug salt-salbutamol formate and preparation method thereof

A kind of technology of albuterol and formic acid, which is applied in the new albuterol pharmaceutical salt-salbutamol formate and the preparation field thereof, and can solve the problems such as no reports of albuterol formate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

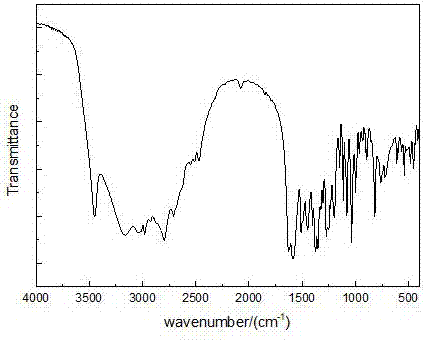

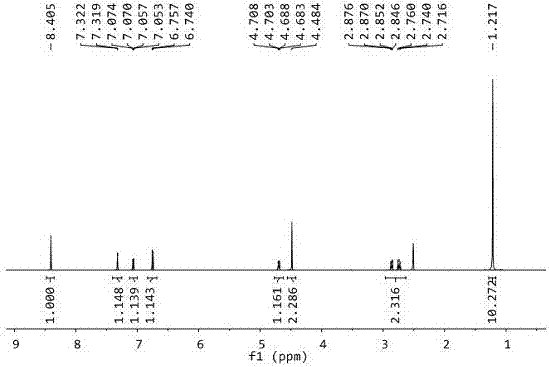

Method used

Image

Examples

Embodiment 1

[0023] Add the methanol solution containing 0.46g of formic acid dropwise to the methanol solution containing 2.40g of the salbutamol raw material under magnetic stirring. After the dropwise addition is complete, continue the magnetic stirring reaction for 4h, then pour the reaction solution into a 100ml beaker. The solvent was naturally evaporated, and when a large amount of crystals were formed, the crystals were recovered by filtration, and then recrystallized twice with ethanol, and the yield was calculated after vacuum drying at 65°C for 24 hours, and the yield was 70%.

Embodiment 2

[0025] Add the methanol solution containing 0.23g of formic acid dropwise to the methanol solution containing 1.20g of salbutamol raw material under magnetic stirring. After the dropwise addition is complete, continue the magnetic stirring reaction for 3h, then pour the reaction solution into a 100ml beaker, and The solvent was naturally evaporated, and when a large amount of crystals were formed, the crystals were recovered by filtration, and then recrystallized twice with ethanol, and the yield was calculated after vacuum drying at 65°C for 24 hours, and the yield was 68%.

Embodiment 3

[0027] Add the ethanol solution containing 0.92g of formic acid dropwise to the ethanol solution containing 4.80g of salbutamol raw material under magnetic stirring, after the dropwise addition is complete, continue the magnetic stirring reaction for 4h, then pour the reaction solution into a 100ml beaker, and The solvent was naturally evaporated, and when a large amount of crystals were formed, the crystals were recovered by filtration, and then recrystallized twice with ethanol, and the yield was calculated after vacuum drying at 65°C for 24 hours, and the yield was 64%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com