Liquid epoxy resin composition

A liquid epoxy resin, epoxy resin technology, applied in the direction of epoxy resin glue, adhesive type, adhesive, etc., can solve the problems of high water absorption, poor moisture resistance reliability, etc., to achieve no damage to reliability and adhesion. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0083] Method for preparing the composition

[0084] The liquid epoxy resin composition of the present invention can be prepared, for example, by the method shown below.

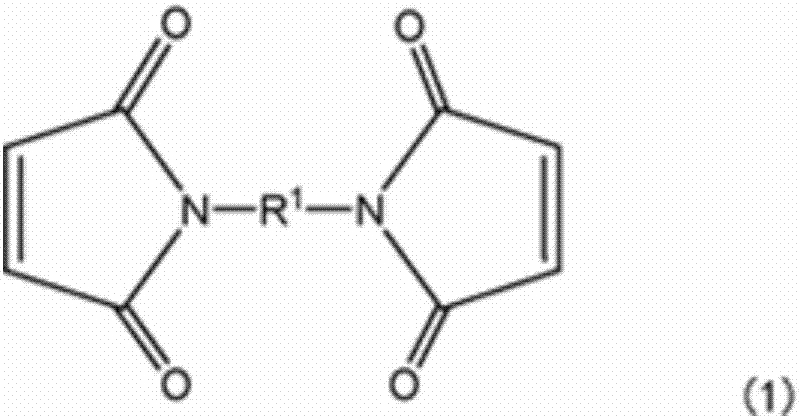

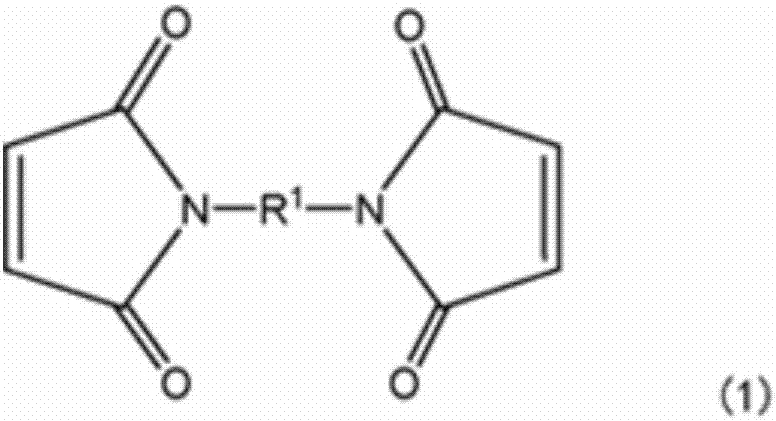

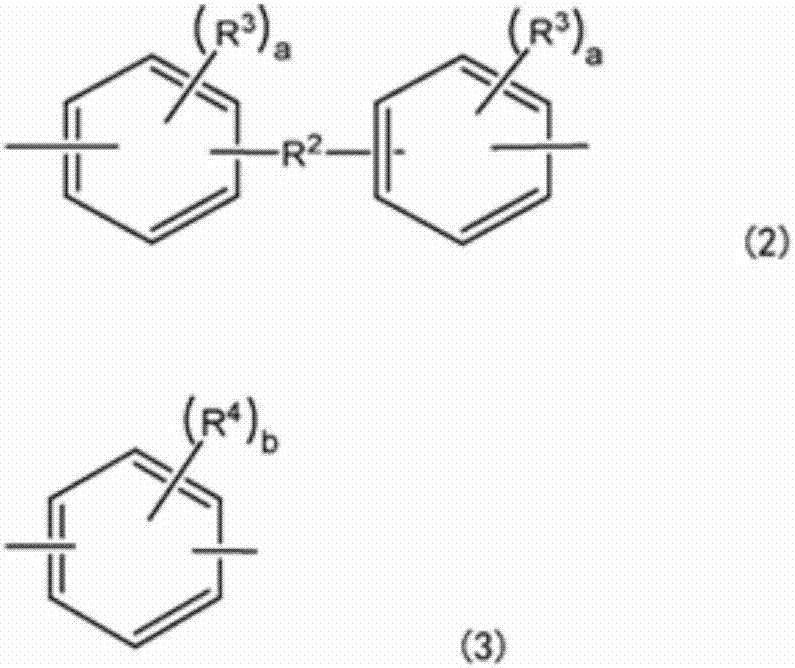

[0085]For example, the (A) component epoxy resin, (B) component imidazole-based curing accelerator, and (C) component maleimide compound are heat-treated, while simultaneously or separately mixing and stirring, and further dissolving and / or disperse to obtain a mixture of (A) component, (B) component and (C) component. It is also possible to add and mix at least one of the other additives of the (D) component of the inorganic filler, mold release agent, flame retardant, and ion trapping agent to the (A) component, (B) component, and (C) component. in the mixture of ingredients. Each component of (A) component - (D) component may be used individually by 1 type, and may use 2 or more types together.

[0086] The preparation method of the composition and the equipment for mixing, stirring and dispersing are ...

Embodiment

[0088] The composition shown in Table 1 was mixed with a planetary mixer at 25° C. and the components shown below were mixed, and then kneaded and mixed using a three-roll mill to prepare a liquid epoxy resin composition.

[0089] In addition, in Table 1, the quantity is shown as a mass part. The molecular weight is the weight average molecular weight (Mw) measured by GPC.

[0090] The prepared compositions were evaluated by the following evaluation methods. The results are shown in Table 1.

[0091] About Examples 1-11 and Comparative Examples 1-7, the composition shown in Table 1 mix|blended each component shown below, and prepared the liquid epoxy resin composition. This liquid epoxy resin composition was further molded under the conditions of 100° C.×2 hours and 150° C.×4 hours to obtain respective cured products.

[0092] (A) epoxy resin

[0093] (1) Epoxy resin (A1): bisphenol A type epoxy resin (YD-8125: manufactured by Tohto Chemical Co., Ltd.)

[0094] (2) Epoxy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com