Cellar-stored raw wine and production method thereof

A production method and cellaring technology, applied in the field of cellaring raw wine and its production, can solve problems such as the need to improve the homogeneity of wine quality and the poor quality of liquor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

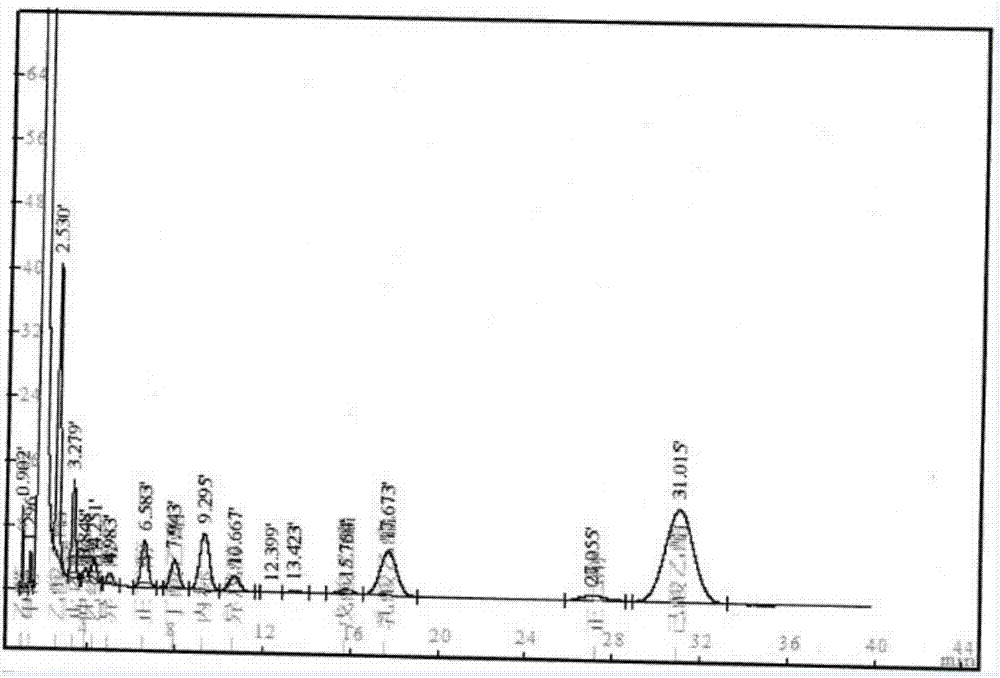

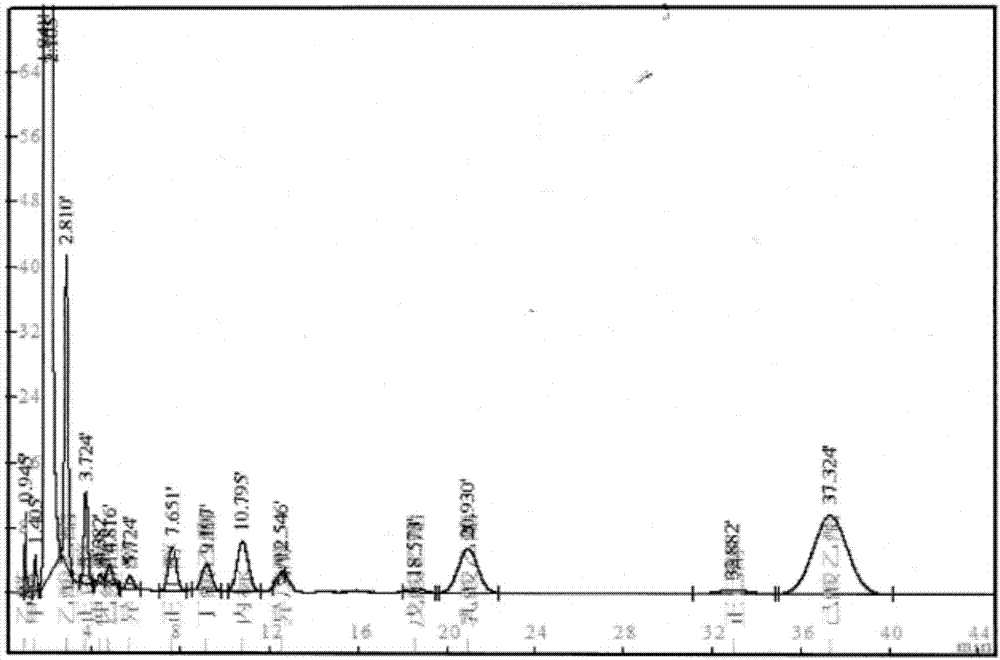

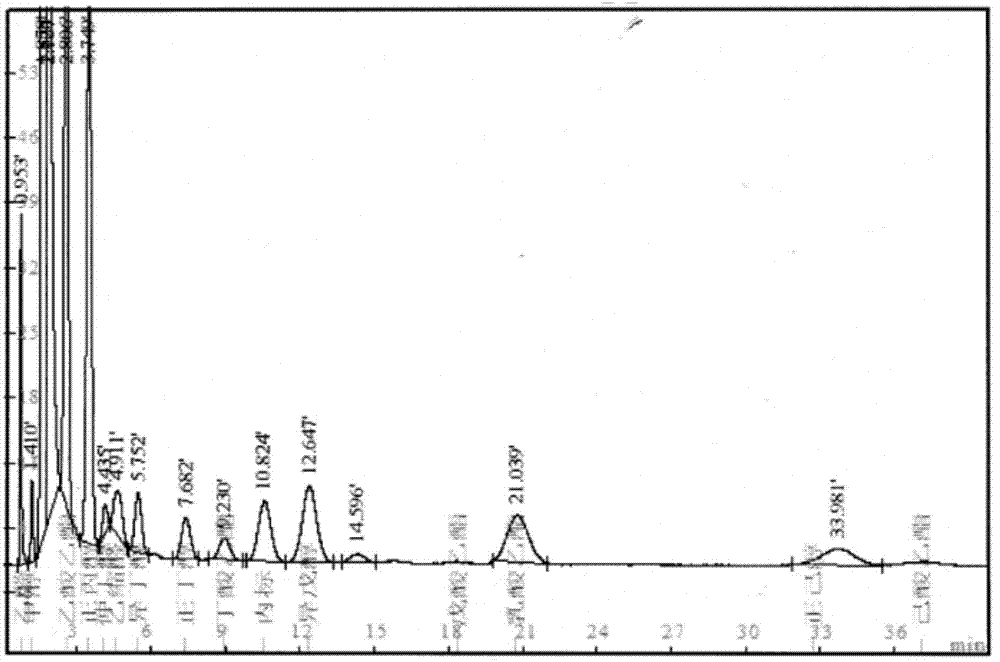

Image

Examples

Embodiment 1

[0043] The present embodiment provides a kind of production method of cellaring former wine, and it comprises:

[0044] Take a 1000ml beaker, put 500ml of distilled water into it, and dissolve 20g of peptone, 5g of beef extract, and 5g of sodium chloride in the water. Adjust the pH value to about 7.2 with 10% sodium hydroxide solution, and set the volume to 1000ml. These liquids were divided into 10 Erlenmeyer flasks, each containing 100ml. Among them, put the chopped agar into five Erlenmeyer flasks, each 3.5g, and add cotton plugs to all ten Erlenmeyer flasks, and wrap them with newspaper. Put the wrapped Erlenmeyer flask into a sterilizer for sterilization for ten minutes. After the time is up, take out the Erlenmeyer flask, pour it into a container, and get a nutrient agar plate after it cools down.

[0045] Select 4 evenly distributed sampling points on the diagonal of Qu Pharmacy, place the nutrient agar plate at the 4 sampling points, and use the impact type air micr...

Embodiment 2

[0049] This embodiment provides a production method for cellaring raw wine, which is basically the same as in Example 1, the difference being that the components of the nutrient agar medium in the nutrient agar plate are different. In this embodiment, the composition of the nutrient agar medium The components include: peptone 20g, beef extract 5g, sodium chloride 2g, agar 15g and distilled water 1000ml.

Embodiment 3

[0051] This embodiment provides a production method for cellaring raw wine, which is basically the same as in Example 1, the difference being that the components of the nutrient agar medium in the nutrient agar plate are different. In this embodiment, the composition of the nutrient agar medium The components include: peptone 30g, beef extract 1g, sodium chloride 8g, agar 20g and distilled water 1000ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com