Soluble fiber, soluble fiber board and preparation method thereof

A fiberboard and fiber technology, which is applied in the field of soluble fiber, soluble fiberboard and its preparation, can solve problems such as poor mechanical properties and limited application, and achieve excellent high-temperature mechanical properties, solving limited use, and good compressive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention has no special limitation on the preparation method of the above-mentioned soluble fiber, and the preparation method of the soluble fiber well-known to those skilled in the art can be adopted. In the present invention, the soluble fiber is preferably prepared according to the following method:

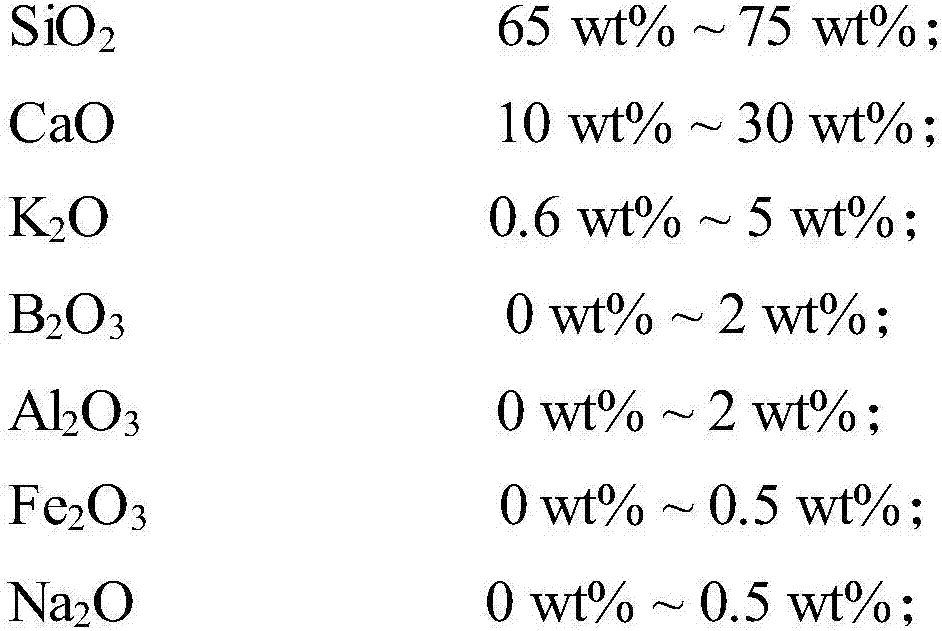

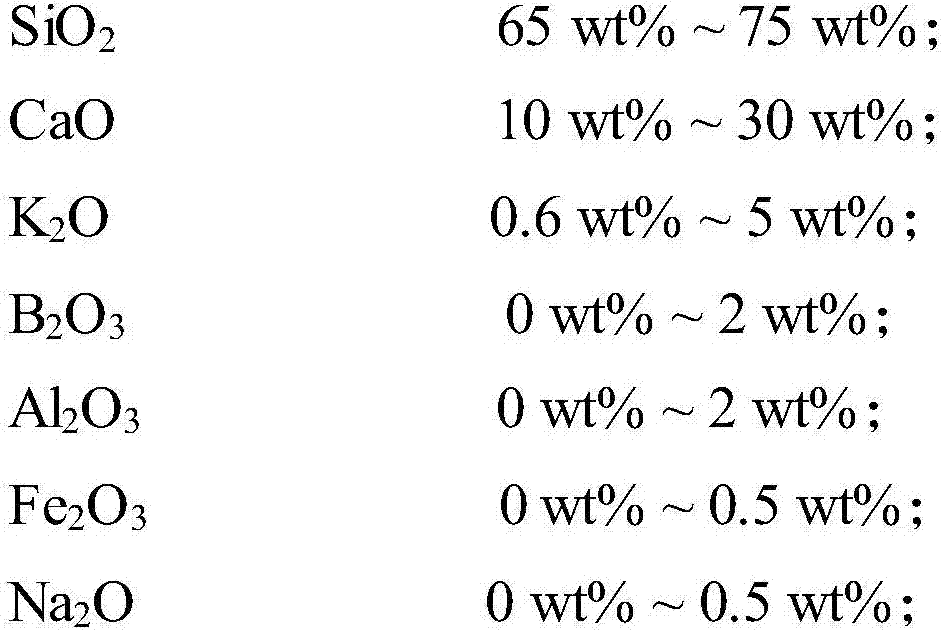

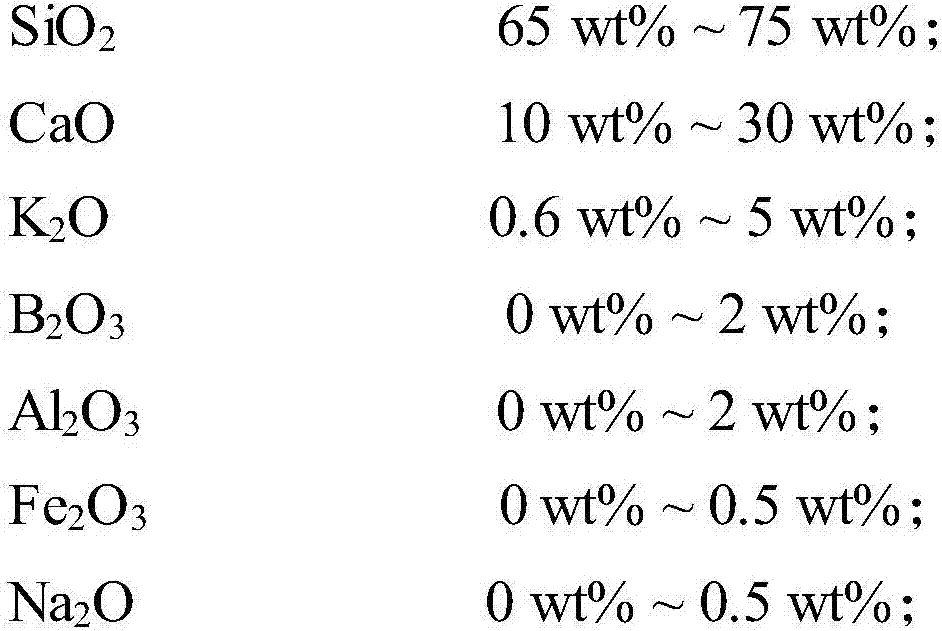

[0040] SiO 2 , CaO, K 2 O.B 2 o 3 、Al 2 o 3 , Fe 2 o 3 and Na 2 O mixing, co-melting and spinning or blowing into fibers to obtain soluble fibers.

[0041] The SiO 2 , CaO, K 2 O.B 2 o 3 、Al 2 o 3 , Fe 2 o 3 and Na 2 The proportioning ratio of O is the same as above, and will not be repeated here.

[0042] The eutectic temperature is preferably 1750-1900°C; in some embodiments of the present invention, the eutectic temperature is 1800°C, 1850°C or 1900°C. The eutectic pressure is preferably 0.101-0.102 MPa, and in some embodiments of the present invention, the eutectic pressure is 0.101 or 0.102 MPa. The eutectic time is preferably 120-3...

Embodiment 1

[0070] 69.28wt% SiO 2 , 27.19wt% CaO, 1.5wt% K 2 O, 0.1 wt% B 2 o 3 , 1.5wt% Al 2 o 3 , 0.13wt% Fe 2 o 3 and 0.3 wt% Na 2 O mixing, at 1800°C, 0.101MPa, co-melting for 180min, then naturally cooling to 1550°C, spinning into fibers to obtain soluble fibers.

[0071] Put 100 parts by weight of the above-mentioned soluble fibers into a hydropulper pre-injected with water, turn on the beater, beat for 30 minutes, and cut the length of the soluble fibers to 3-5 mm;

[0072] Pump the crushed soluble fiber slurry into the stock tank, add water, dilute the crushed soluble fiber slurry to a concentration of 1.0wt% to 2.0wt%, and then remove the slag by screw The slag removal device is used to obtain the soluble fiber slurry after the slag removal;

[0073] The soluble fiber slurry obtained through the above-mentioned treatment is stirred and mixed with the organic binder of 7 parts by weight and the inorganic binder of 10 parts by weight for 20 minutes; the organic binder is t...

Embodiment 2

[0076] 71.2wt% SiO 2 , 24.27wt% CaO, 2.2wt% K 2 O, 0.15 wt% B 2 o 3 , 1.76wt% Al 2 o 3 , 0.14wt% Fe 2 o 3 and 0.28 wt% Na 2 O mixing, at 1850°C, 0.102MPa, co-melting for 240min, then naturally cooling to 1650°C, spinning into fibers to obtain soluble fibers.

[0077] Put 100 parts by weight of the above-mentioned soluble fibers into a hydropulper pre-injected with water, turn on the beater, beat for 30 minutes, and cut the length of the soluble fibers to 3-5 mm;

[0078] Pump the crushed soluble fiber slurry into the stock tank, add water, dilute the crushed soluble fiber slurry to a concentration of 1.0wt% to 2.0wt%, and then remove the slag by screw The slag removal device is used to obtain the soluble fiber slurry after the slag removal;

[0079] The soluble fiber slurry obtained through the above-mentioned treatment is stirred and mixed with the organic binder of 7 parts by weight and the inorganic binder of 10 parts by weight for 20 minutes; the organic binder is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com