Modified film for packaging alcohol and drink and preparation method of modified film

A film preparation and beverage technology, which is applied in applications, household utensils, flat products, etc., can solve problems that need to be further improved, and achieve the effects of uniform vertical and horizontal shrinkage, cheap price, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

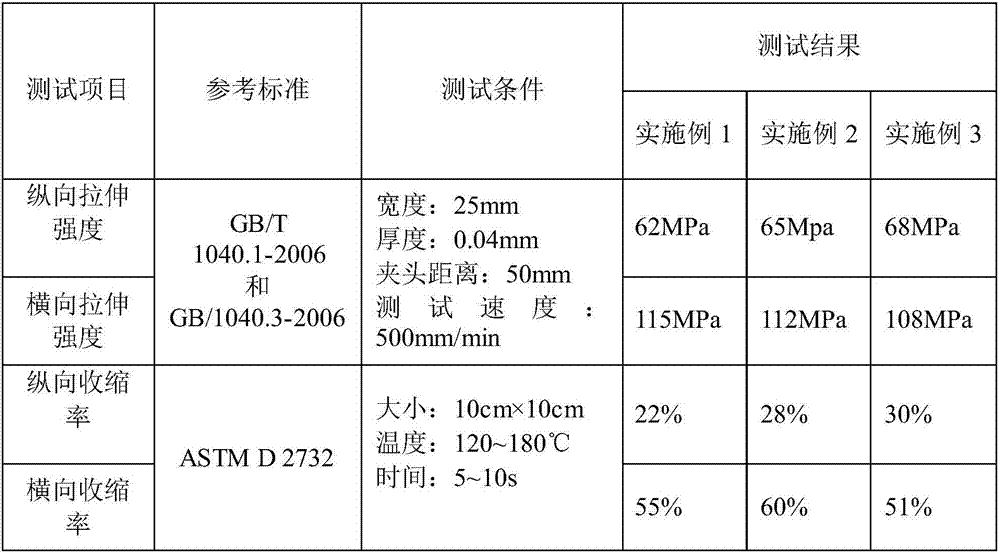

Examples

Embodiment 1

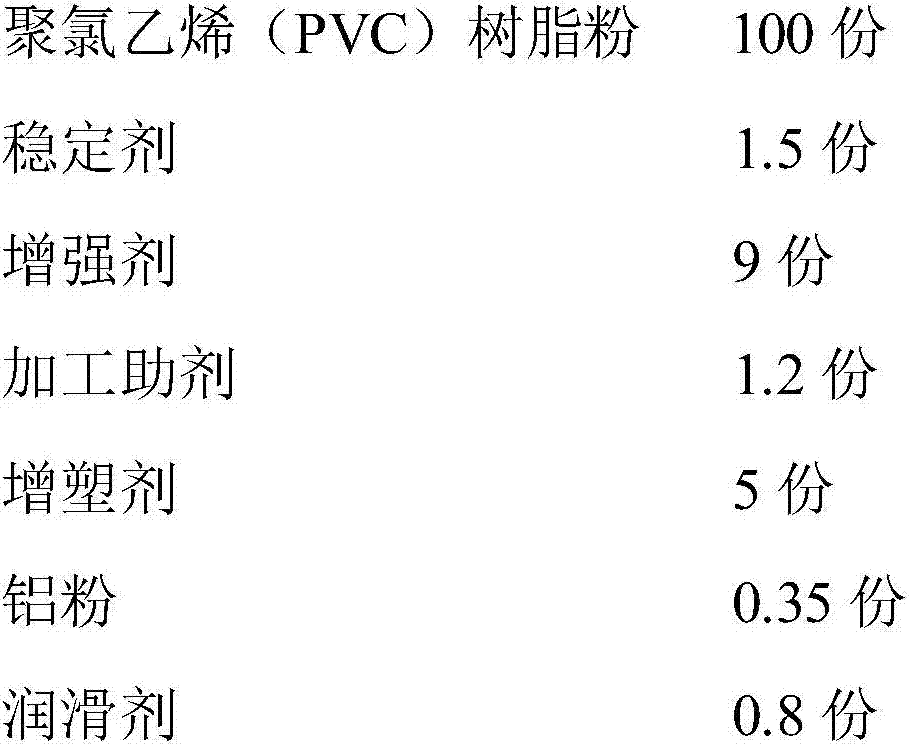

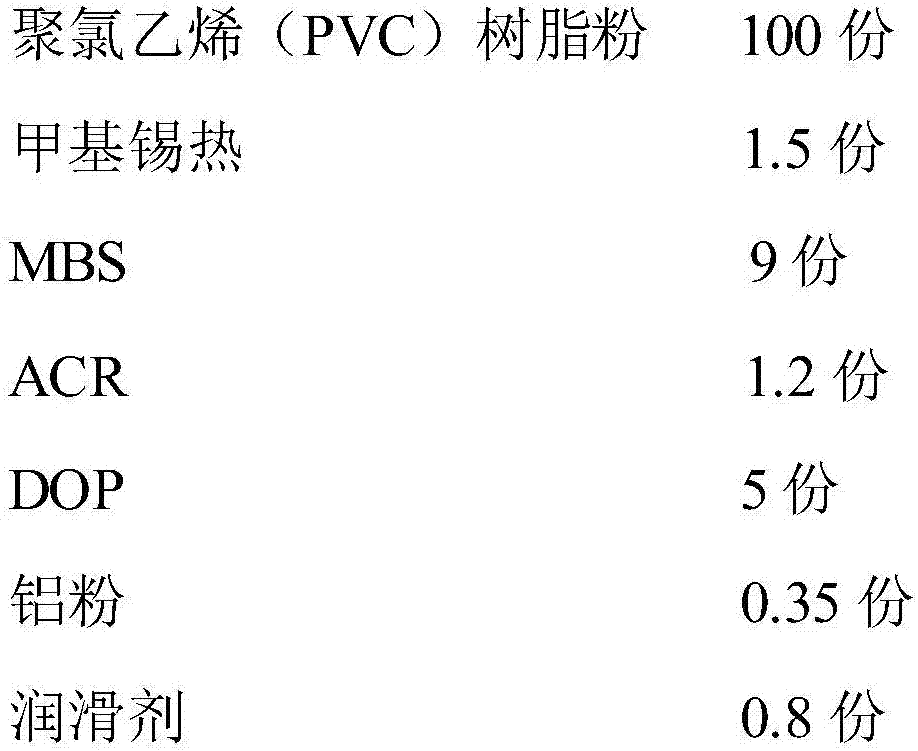

[0031] A modified film used for the packaging of alcoholic beverages, which consists of the following components in weight percentage:

[0032]

[0033] The lubricant is one or a mixture of two or more of oxidized polyethylene wax, homopolymer lubricant or fatty acid complex grease.

[0034] Described a kind of modified film preparation method for packaging of alcoholic beverages comprises the following steps:

[0035] Step 1. Production of finished powder

[0036] 1) Put the polyvinyl chloride resin powder into a high-speed mixer with cold mixing and stir, and the polyvinyl chloride resin powder generates heat by friction during the stirring process;

[0037] 2) Add stabilizer (methyl tin heat stabilizer), lubricant and plasticizer (DOP) at 60°C;

[0038] 3) Add enhancer (MBS), processing aid (ACR) and aluminum powder at 110°C;

[0039] 4) Finish mixing at 125°C, put it into a cold mixing pot for forced cooling;

[0040] Step 2, film production

[0041] 1) Put the coo...

Embodiment 2

[0047] A modified film used for the packaging of alcoholic beverages, the formula components are the same as those in Example 1.

[0048] Described a kind of modified film preparation method for packaging of alcoholic beverages comprises the following steps:

[0049] Step 1. Production of finished powder

[0050] 1) Put the polyvinyl chloride resin powder into a high-speed mixer with cold mixing and stir, and the polyvinyl chloride resin powder generates heat by friction during the stirring process;

[0051] 2) Add stabilizer (methyl tin heat stabilizer), lubricant and plasticizer (DOP) at 65°C;

[0052] 3) Dosing enhancer (MBS), processing aid (ACR) and aluminum powder at 90°C;

[0053] 4) Finish mixing at 125°C, put it into a cold mixing pot for forced cooling;

[0054] Step 2, film production

[0055] 1) Put the cooled finished product powder obtained in step 1 into the screw of the calendering tablet machine for melting. The screw is a planetary screw, and the screw pa...

Embodiment 3

[0061] A modified film used for the packaging of alcoholic beverages, the formula components are the same as those in Example 1.

[0062] Described a kind of modified film preparation method for packaging of alcoholic beverages comprises the following steps:

[0063] Step 1. Production of finished powder

[0064] 1) Put the polyvinyl chloride resin powder into a high-speed mixer with cold mixing and stir, and the polyvinyl chloride resin powder generates heat by friction during the stirring process;

[0065] 2) Add stabilizer (methyl tin heat stabilizer), lubricant and plasticizer (DOP) at 70°C;

[0066] 3) Add enhancer (MBS), processing aid (ACR) and aluminum powder at 100°C;

[0067] 4) Finish mixing at 125°C, put it into a cold mixing pot for forced cooling;

[0068] Step 2. Film production

[0069] 1) Put the cooled finished product powder obtained in step 1 into the screw of the calendering tablet machine for melting. The screw is a planetary screw, and the screw part i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com