Halogen-free flame retardant hot-melt adhesive film used on high-frequency transmission wire rod

A high-frequency transmission, hot-melt adhesive film technology, applied in the direction of heat-activated films/sheets, adhesives, film/sheet-like adhesives, etc. Influence of transmission performance, low temperature resistance and scratch resistance, etc., to achieve good halogen-free flame retardant insulation and high temperature resistance, stable structure, and improved scratch resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

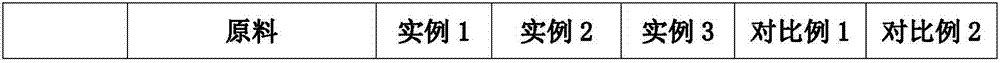

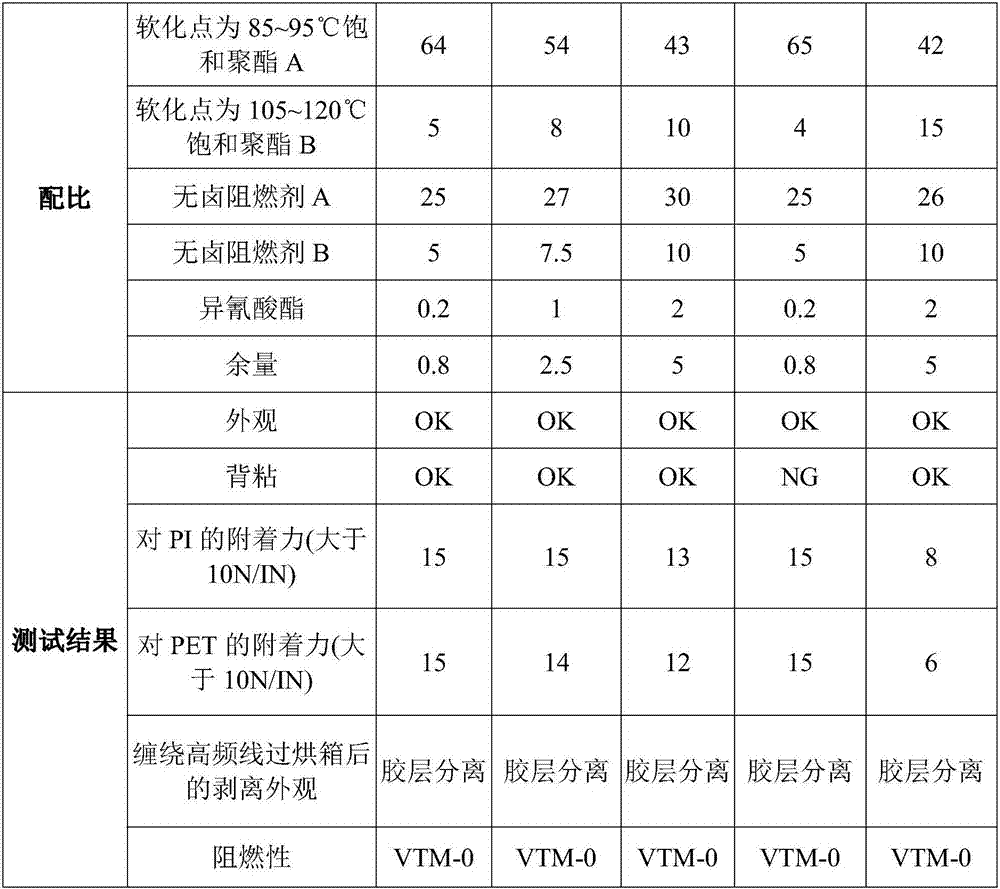

[0019] Example - a halogen-free flame-retardant hot-melt adhesive film used on high-frequency transmission wires, the adhesive layer is prepared according to the different raw material components and proportions in the following table, and then the adhesive layer is coated on the insulating film Layer to obtain different halogen-free flame-retardant hot-melt adhesive films; and conduct the following performance tests:

[0020] (1) Appearance

[0021] After the adhesive layer is coated on the surface of the insulating film layer, check whether there are bubbles, pinholes, or particles on the adhesive layer.

[0022] (2) back adhesive

[0023] Use the adhesive layer of the finished adhesive film that has been coated on the PET surface or the PI surface to be evenly pasted on the non-corona surface of PET or the non-corona surface of PI. The size of the sample is 50mmX200mm, here Place a 5kg weight flatly on the sample, and test the peeling force of the sample after placing it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com