Structure for PCCP bell and spigot joint, pipeline and construction method

An epoxy coating, high toughness technology, applied in the sewer system, waterway system, water supply device and other directions, can solve the problem that the polysulfide sealant is not tightly combined with the interface ring, the base surface is clean and difficult to achieve, and the construction quality is difficult to achieve. hidden dangers and other problems, to achieve the effect of excellent anti-backwater pressure capability, simple construction and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

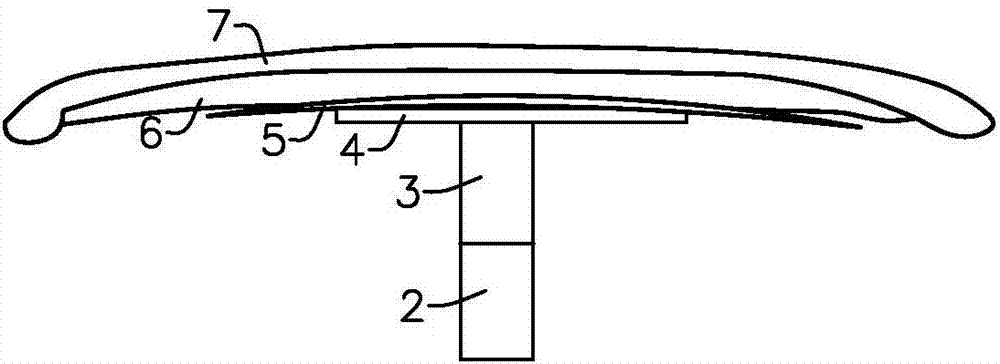

[0046] The pipeline formed by the PCCP pipe connection of this embodiment includes a plurality of end-to-end PCCP pipes, and the position of the socket between two adjacent PCCP pipes forms a seam, the seam has a filling structure, and the filling structure includes primer, plastic Sealing material 2, epoxy putty 3, isolation layer 4, bottom high-toughness epoxy coating 5, dipped glass fiber tape 6 and surface high-toughness epoxy coating 7, wherein the primer is used to brush on the joints On the inner wall, plastic sealing material 2, epoxy putty 3, isolation layer 4, bottom high-toughness epoxy coating 5, dipped glass fiber tape 6 and surface high-toughness epoxy coating 7 are arranged in sequence.

[0047] Wherein, the extension direction of the filling structure is the same as that of the PCCP pipe, and the primer, plastic sealing material 2, and epoxy putty 3 are arranged on the inner side of the joint, and the isolation layer 4, the bottom high-toughness epoxy coating 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com