Low-frequency sound absorber allowing passing of fluid

A sound absorber and fluid technology, applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., can solve the problems of occupying a large area, permanent deformation of the film, and non-environmental protection, so as to avoid creep permanent deformation, Thickness requirements are reduced and the effect of reducing low-frequency noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0045] The present invention will be described in detail below with reference to the accompanying drawings and examples.

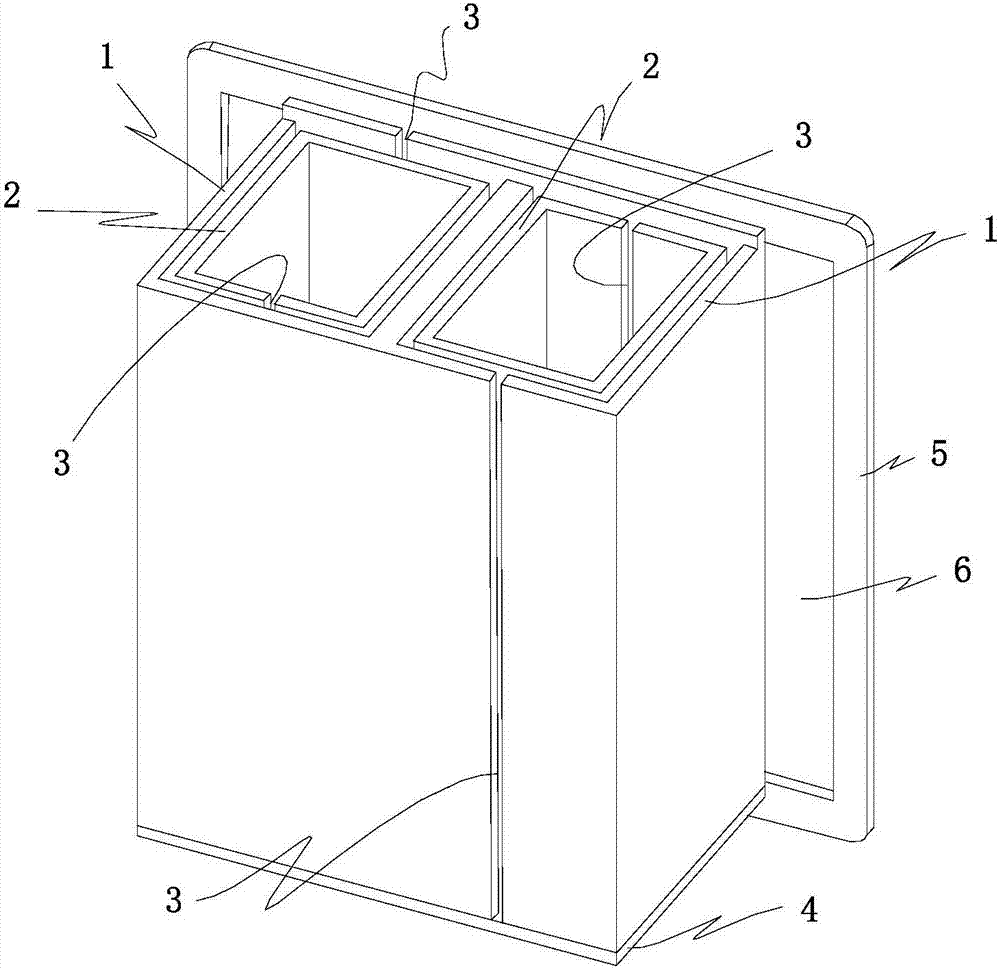

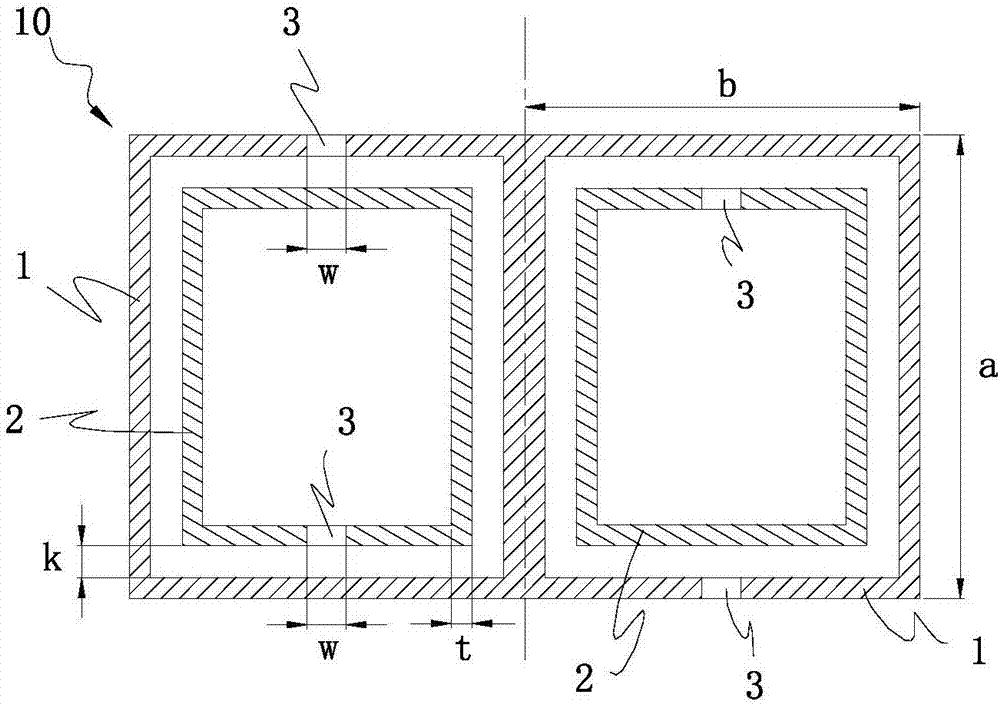

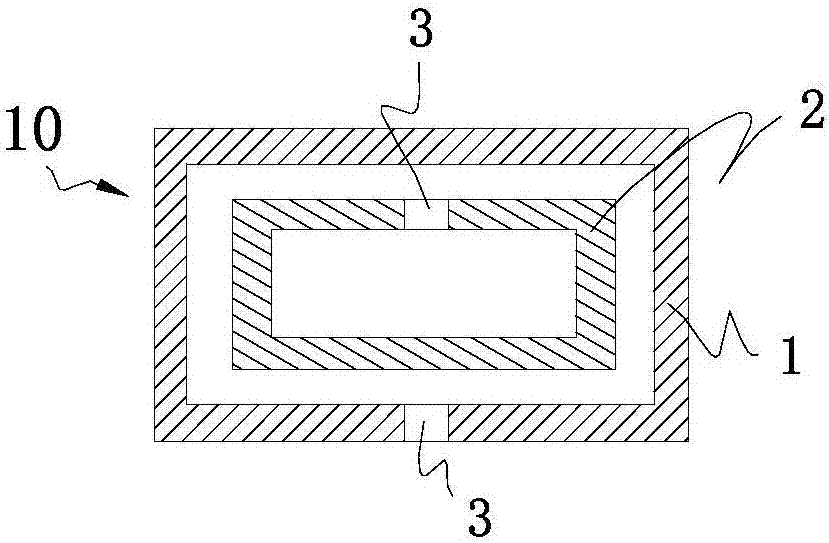

[0046] This embodiment relates to a low-frequency sound absorber that allows fluid to pass through (hereinafter referred to as "low-frequency sound absorber"). gap, and the sound-absorbing unit specifically includes a hollow pipe body, and plates respectively arranged at both ends of the pipe body to close the two ends of the pipe body. At the same time, the side wall of the pipe body is also provided with Open your mouth.

[0047] When working, the low-frequency sound absorber of this embodiment can allow the fluid to pass through the low-frequency sound absorber through the setting of the gap between the sound-absorbing units, and through the setting of the pipe body with openings and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com