A kind of perovskite solar cell and preparation method thereof

A solar cell and perovskite-type technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of inability to prepare high-quality large-area devices, difficulty in precisely controlling sublimation, and uneven PbI reaction. Effects of short time, reduced film defects, and improved film coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

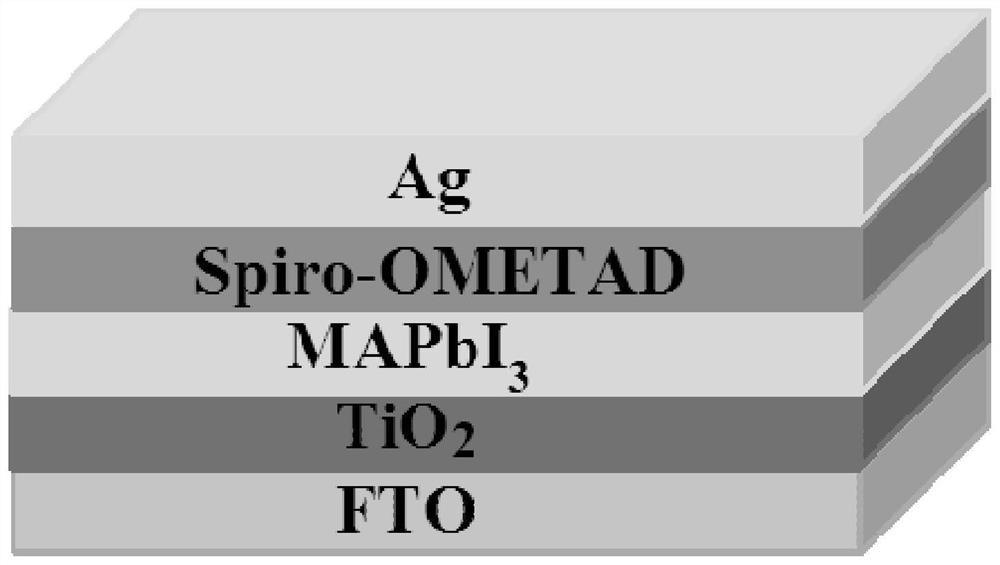

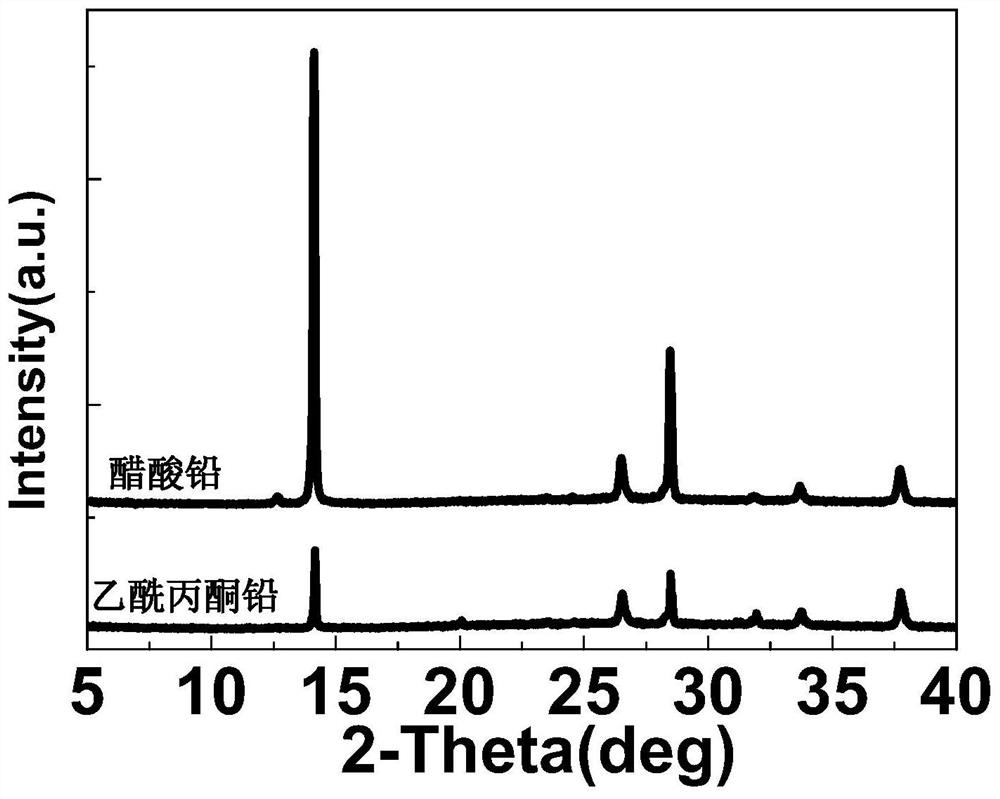

[0040] Example 1. Preparation of perovskite solar cells with lead acetylacetonate as lead source by simple near-space sublimation method

[0041] 1) Preparation of electron transport layer

[0042] Preparation of dense film layer:

[0043]Prepare according to the conventional method, and the compact film layer is prepared according to the method provided by the following documents: LeadIodide Perovskite Sensitized All-Solid-State Submicron Thin Film Mesoscopic Solar Cell with Efficiency Exceeding 9%, H.S.Kim, C.R.Lee, J.H.Im, K.B.Lee, T. Moehl, A. Marchioro, S. J. Moon, R. Humphry-Baker, J. H. Yum, J. E. Moser, M. Gratzel and N. G. Park, Scientific Reports, 2012, 2, 591;

[0044] The specific steps are:

[0045] The titania dense layer was prepared by spin coating, the precursor solution of the dense layer was coated on the surface of the conductive glass, and the film was spun off for 60s at a rotational speed of 2000rpm. Immediately after the end, place the film on a hot ...

Embodiment 2

[0058] Example 2. Preparation of perovskite solar cells with lead acetate as lead source by simple near-space sublimation method

[0059] According to the steps of Example 1, only the lead acetylacetonate used in step 2) was replaced with lead acetate, and the temperature used was 110°C.

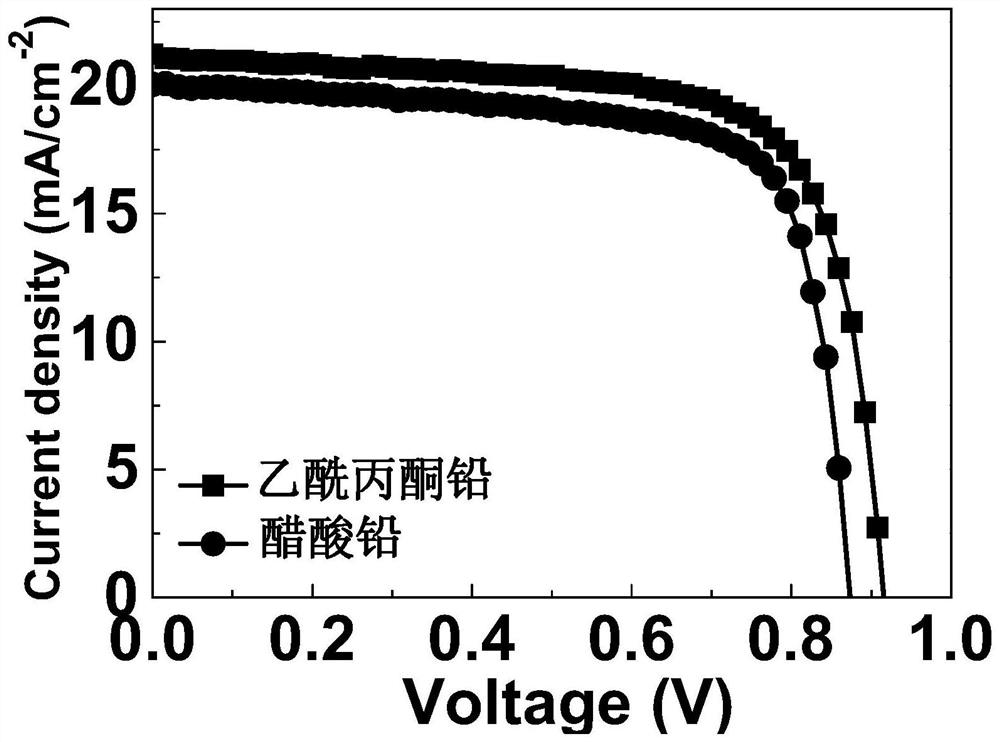

[0060] In AM1.5, 100mW / cm 2 Test the J-V performance curve of the battery with KEITHLEY 4200 under light, such as image 3 As shown in , the short-circuit current density of the battery is 20.05mA / cm 2 , the open circuit voltage is 0.87V, the fill factor is 0.73, and the photoelectric conversion efficiency is 12.95%.

[0061] The preparation of perovskite solar cells by a simple near-space sublimation method can be prepared at low temperature, and the film coverage is greatly improved. It can be used to make large-area devices, providing a feasible method for future industrialization. In conclusion, the present invention can greatly reduce the production cost, which is of great significan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com