A five-element high-entropy oxide nanofilm for lithium-ion batteries and its preparation and application

A lithium-ion battery and nano-film technology, which is applied to the five-element high-entropy oxide nano-film of lithium-ion batteries and its preparation and application fields, can solve the problems of low charge-discharge specific capacity, volume expansion, poor cycle stability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

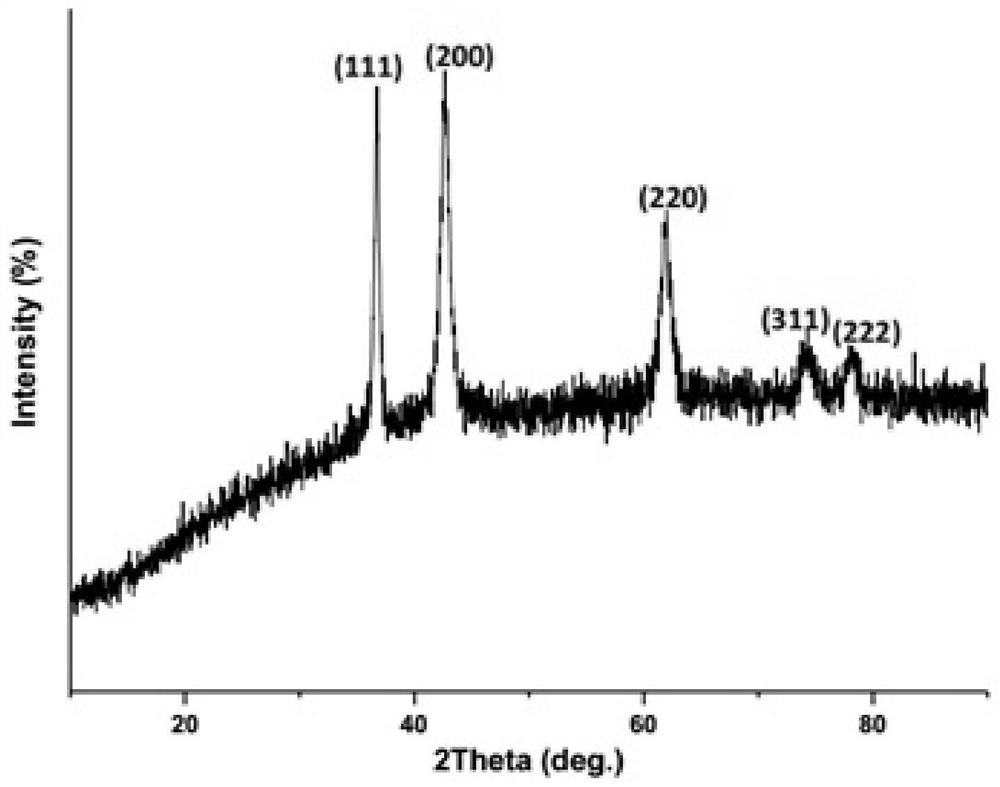

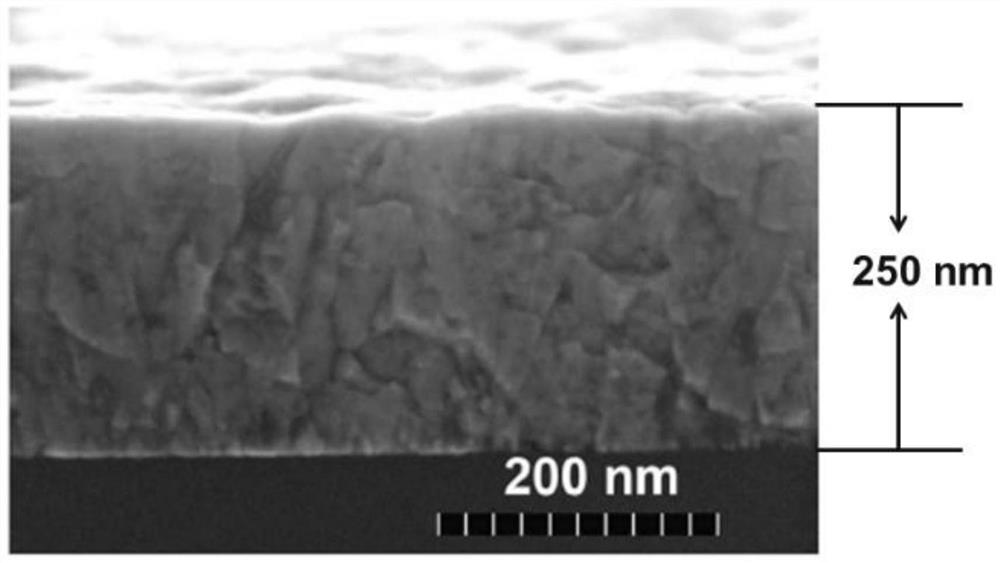

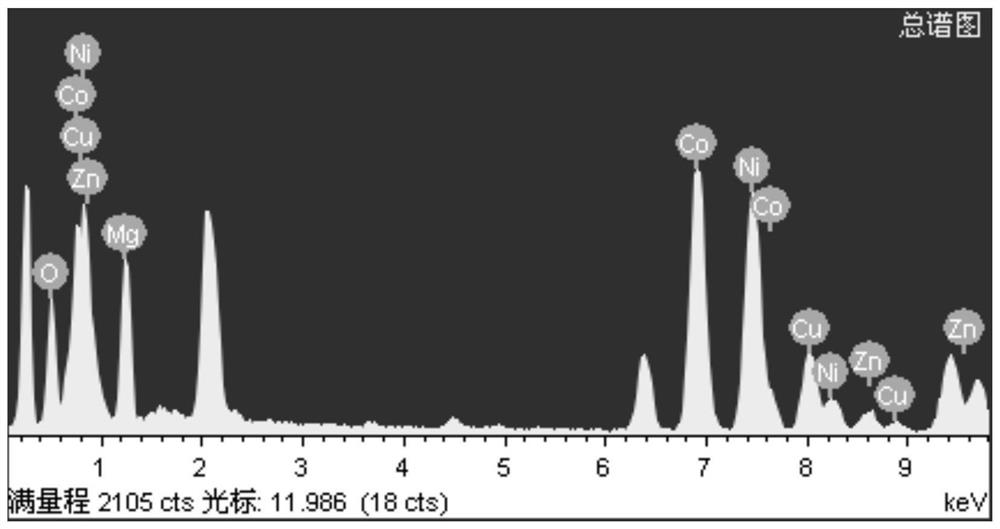

[0028] Adopt laser molecular beam epitaxy deposition technology to prepare high-entropy oxide (Mg 0.2 co 0.2 Ni 0.2 Cu 0.2 Zn 0.2 )O thin film: According to the molar ratio (0.2 / 0.2 / 0.2 / 0.2 / 0.2), magnesium oxide, cobalt oxide, nickel oxide, copper oxide and zinc oxide are high-energy ball milled for 10-15 hours, mixed evenly and pressed into tablets to make laser molecules The target used for beam epitaxy deposition, the 1064nm fundamental frequency generated by the neodymium-doped yttrium aluminum garnet laser is tripled to obtain a 355nm pulsed laser, the laser beam is incident on the above target after being focused by the lens, the target and the substrate The distance is 30mm, high vacuum (1.0×10 -6 (Mg 0.2 co 0.2 Ni 0.2 Cu 0.2 Zn 0.2 )O thin film, in which the substrate is made of high-purity platinum, and the substrate temperature is 700°C.

[0029] The deposition time of the film is determined by the film thickness requirements, generally 1 to 2 hours. The t...

Embodiment 2

[0033] The high-entropy oxide (MgO) as the negative electrode material for lithium ion battery according to the present invention is prepared by laser molecular beam epitaxy deposition technology 0.25 Co 0.15 Ni 0.2 Cu 0.2 Zn 0.2 )O thin film: According to the molar ratio (0.25 / 0.15 / 0.2 / 0.2 / 0.2), high-energy ball milling of magnesium oxide, cobalt oxide, nickel oxide, copper oxide and zinc oxide for 10-15 hours, mixed evenly, and pressed into sheets to make laser molecules The target used for beam epitaxy deposition, the 1064nm fundamental frequency generated by the neodymium-doped yttrium aluminum garnet laser is tripled to obtain a 355nm pulsed laser, the laser beam is focused by a lens and then incident on the above target, the distance between the target and the substrate 20mm, 1.0×10 in high vacuum -6 (Mg) deposited on the substrate under Pa 0.25 Co 0.15 Ni 0.2 Cu 0.2 Zn 0.2 )O film, wherein the substrate is made of stainless steel, and the substrate temperature ...

Embodiment 3

[0038] The high-entropy oxide (MgO) as the negative electrode material for lithium ion battery according to the present invention is prepared by laser molecular beam epitaxy deposition technology 0.2 Co 0.2 Ni 0.3 Cu 0.15 Zn 0.15 )O thin film: According to the molar ratio (0.2 / 0.2 / 0.3 / 0.15 / 0.15), high-energy ball milling of magnesium oxide, cobalt oxide, nickel oxide, copper oxide and zinc oxide for 10-15 hours, mixed evenly, and pressed into sheets to make laser molecules The target used for beam epitaxy deposition, the 1064nm fundamental frequency generated by the neodymium-doped yttrium-aluminum garnet laser is tripled to obtain a 355nm pulsed laser, and the laser beam is focused by a lens and incident on the above target. The distance is 40mm, and the high vacuum degree is 1.0×10 -6 (Mg) deposited on the substrate under Pa 0.2 Co 0.2 Ni 0.3 Cu 0.15 Zn 0.15 )O thin film, wherein the substrate is a gold-coated monocrystalline silicon wafer, and the substrate tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com