Permanent magnet brushless direct current motor for automobile window

A permanent magnet brushless DC and car window technology, which is applied in the direction of magnetic circuits, electromechanical devices, electrical components, etc., can solve the problems of electric sparks, low efficiency, and large volume, and achieve long life, high efficiency, and small volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

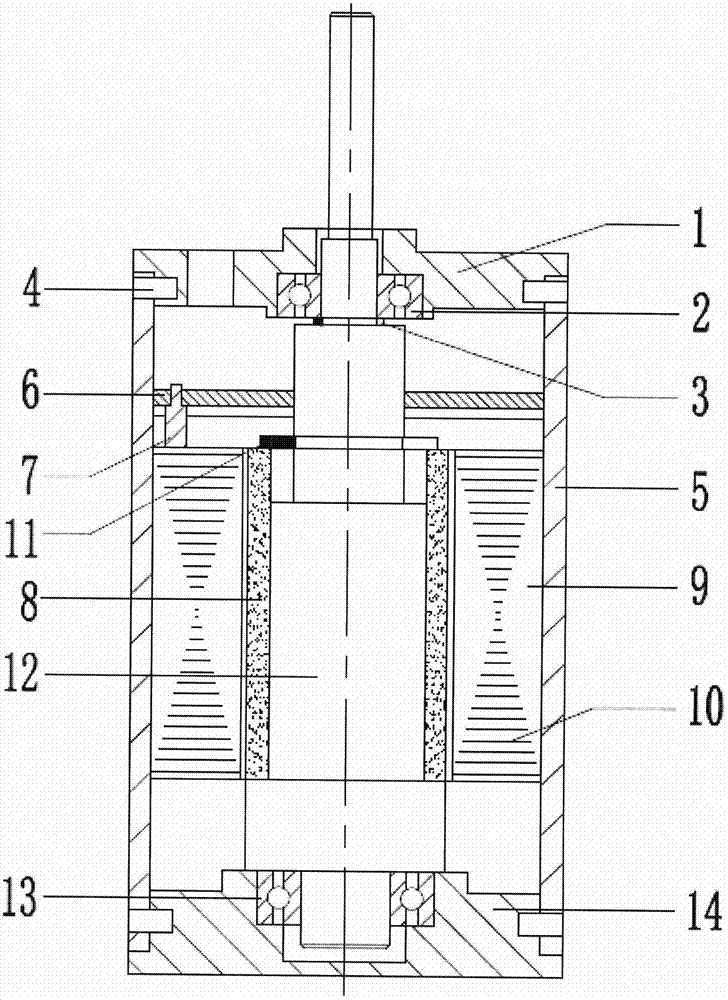

[0028] The present invention as Figure 1 to Figure 13 Shown, the specific embodiment of the present invention is described below in conjunction with accompanying drawing:

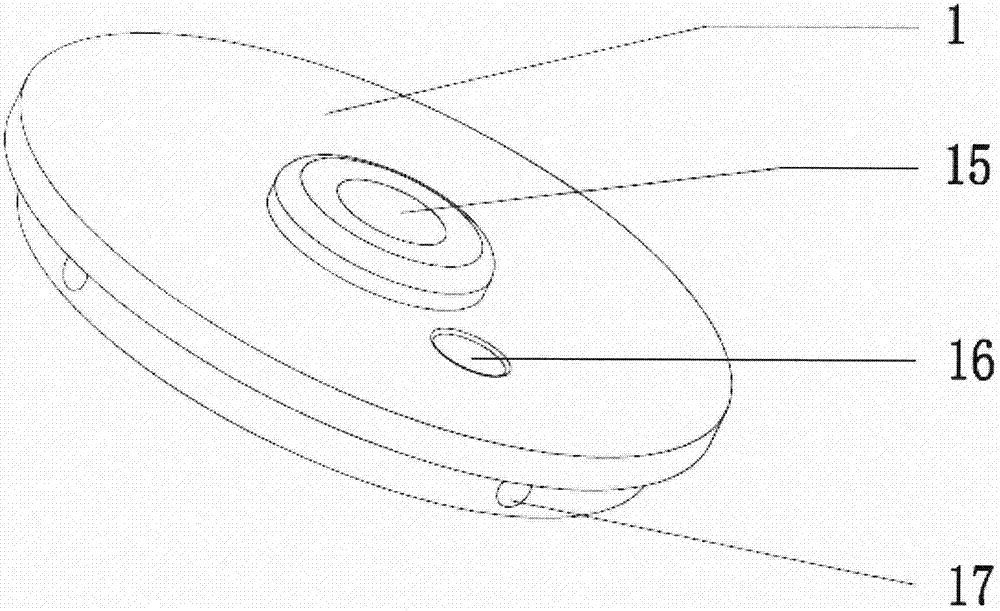

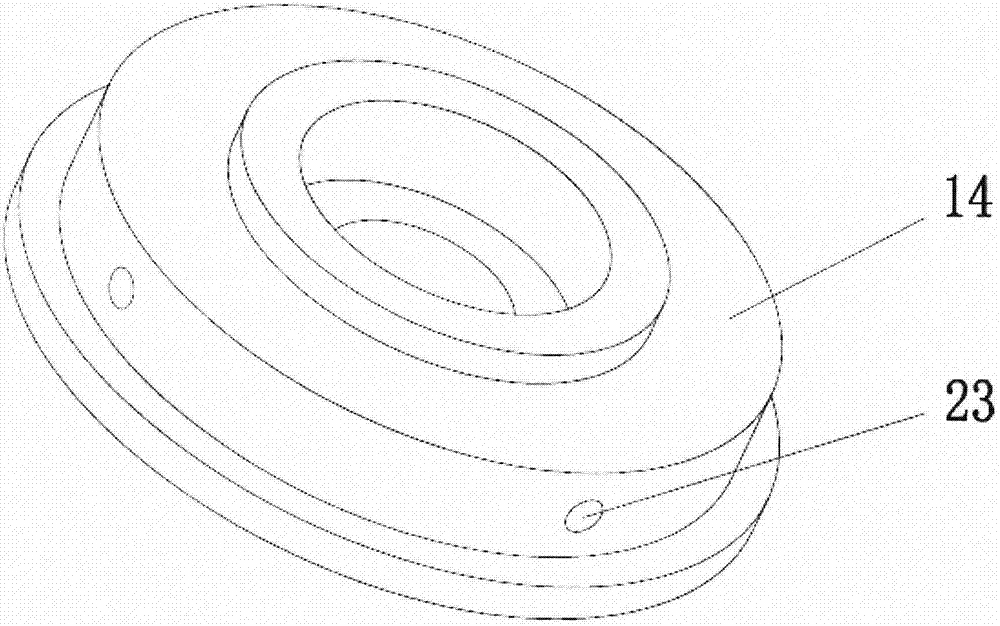

[0029] Such as figure 1 As shown, the permanent magnet brushless DC motor for automobile windows includes: an upper end cover (1), a lower end cover (14), a casing (5), bearings (2, 13), retaining springs (3, 11), Fixed pin (4), mounting plate (6), support frame (7), permanent magnet (8), stator core (9), coil package (10), rotor core (12). in, figure 2 upper end cap (1) shown and image 3 The lower end cover (14) shown is all a hollow cylinder formed by stamping, and the upper end cover (1) has a cylindrical step of stamping support bearing (2) inside, and the center of the upper surface is drilled with a shaft outlet hole (15), and there is an outlet hole ( 16), there are 4 holes (17) fixed to the casing (5) on the side, and there are cylindrical steps for stamping the support bearing (13) inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com