Direct-current motor driving device

A driving device and DC motor technology, which is applied in the direction of DC motor rotation control, excitation or armature current control, etc., can solve the problems of large size, large loss, and serious resource occupation of the main controller port of the motor driver, and achieves low loss, Improve utilization efficiency and reduce volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

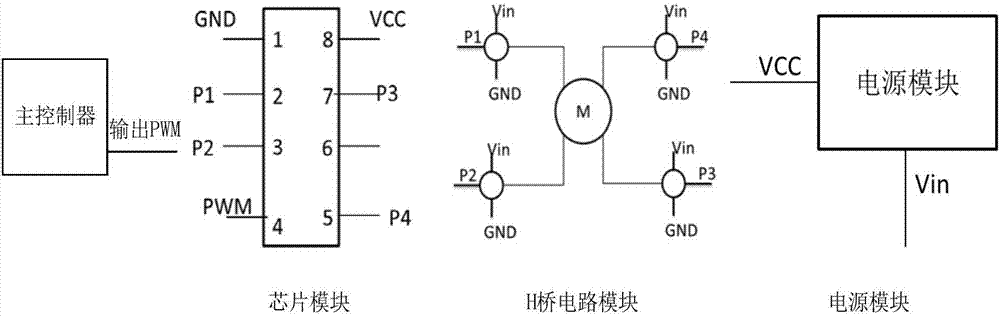

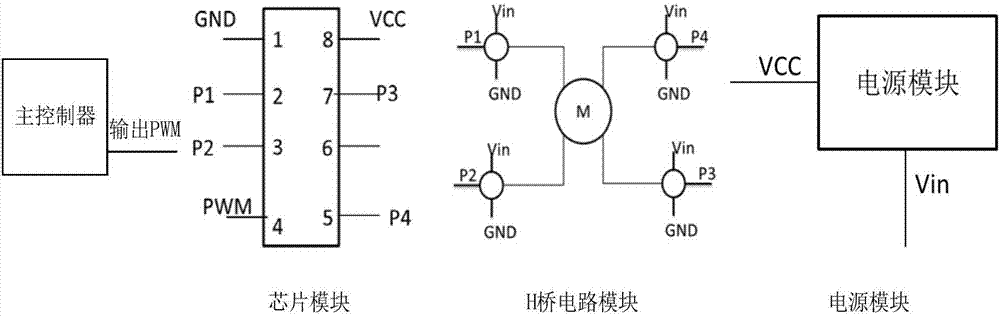

[0022] figure 1 A schematic structural diagram of a DC motor driving device provided in an embodiment of the present invention, wherein a DC motor driving device includes a main controller, a chip module, a power supply module and an H-bridge circuit module.

[0023] The chip module is used to control the output of the output end of the chip module according to the pulse width modulation PWM signal, wherein the chip module includes 8 ports, wherein port 1 is connected to the ground signal, port 2 is the first output port P1, and port 3 is the second output port. The second output terminal P2, the port 4 is the PWM input terminal, the port 5 is the fourth output terminal P4, the port 7 is the third output terminal P3, and the port 8 is the VCC input terminal. The H-bridge circuit module is used to control the forward or reverse rotation of the motor according to the output signal of the output terminal of the chip module; the H-bridge circuit module includes a motor and four co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com