Cleansing Oil

A technology of cleansing oil and glycerin, which is applied in the direction of cosmetics, cosmetics, cosmetic preparations, etc., can solve the problems of reduced cleansing power and greasy residue, and achieve the effects of lightening the burden, small emulsified particle size, and excellent rinse performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] [Evaluation of self-emulsifying properties and cleaning power]

[0062] Prepare the cleansing oil of embodiment 1, comparative example 1, 2 according to the prescription of table 1.

[0063] Table 1

[0064] Element

[0065] Polyglyceryl-20 Hexacaprylate: Eicosyl Hexacaprylate

[0066] Polyglyceryl-20 Octaisononanoate: Octaisononanoate Eicosylglyceride

[0067] Diisononanoic Acid BG: 1,3-Butanediol Diisononanoate

[0068] PEG / PPG / polytetramethylene glycol-8 / 5 / 3 glycerin: NOF Corporation WILBRIDE S-753D

[0069] [Self-emulsifying evaluation]

[0070] experiment method

[0071] 0.1 g of the cleansing oil prepared above was gently added dropwise to 100 g of ion-exchanged water, and left to stand overnight to prepare a 0.1% aq test sample.

[0072] The volume average particle diameter of the prepared test object was measured by the dynamic light scattering method using a zeta potential particle diameter measurement system (apparatus name: ELSZ-1000ZS, manufa...

Embodiment 1

[0077] Compared with Comparative Examples 1 and 2, the particle size of Example 1 is smaller.

[0078] In addition, the smaller the particle size, the higher the self-emulsifying property and the better the cleanability.

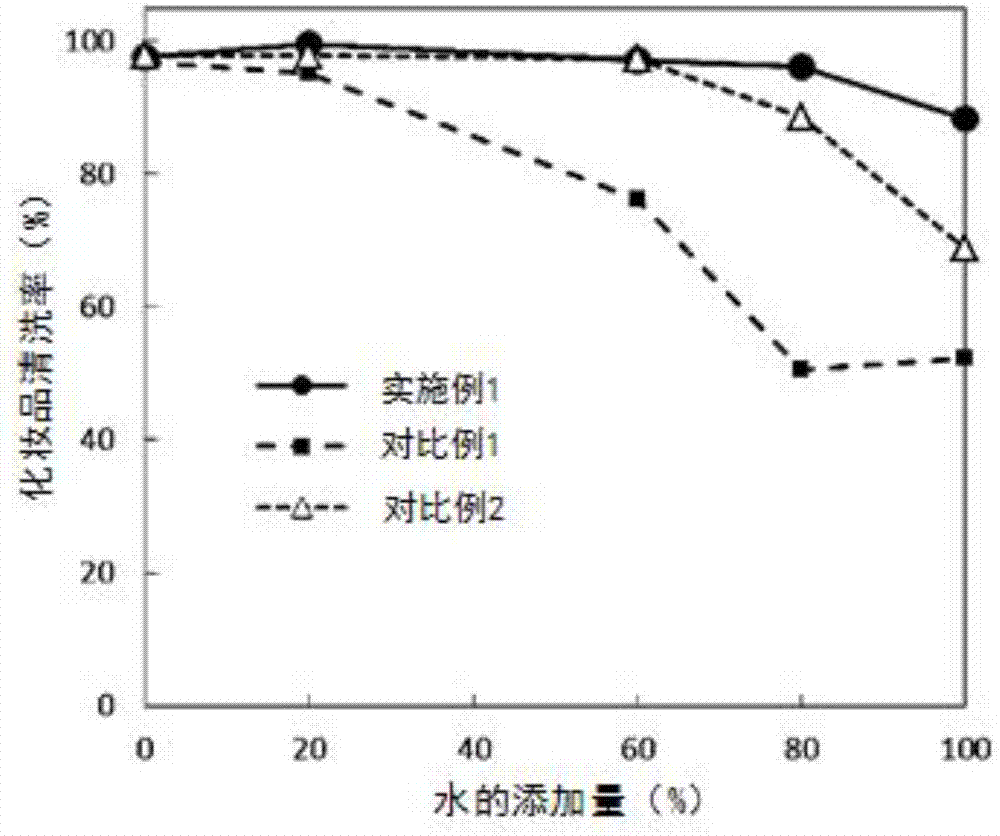

[0079] [evaluation of cleaning power]

[0080] experiment method

[0081] (1) 0.004 g of lipstick (Fancl MoistureRouge P#84 Velvet Red) was applied and dried for 30 minutes within 2 cm x 2 cm of 3 cm x 6 cm white artificial leather. Use it as a test subject.

[0082] (2) The color difference (L1) of the prepared test specimen was measured using a color difference meter (apparatus name: CM-2600d, manufactured by Konica Minolta Co., Ltd.).

[0083] (3) With respect to the weight 100% of the cleansing oil prepared in Example 1 or Comparative Examples 1 and 2, a predetermined amount of water was added to prepare a test sample.

[0084] (4) 0.1 ml of the test sample was added dropwise to the test specimen prepared in the above (1), and rubbed 10 times with a ...

Embodiment 2

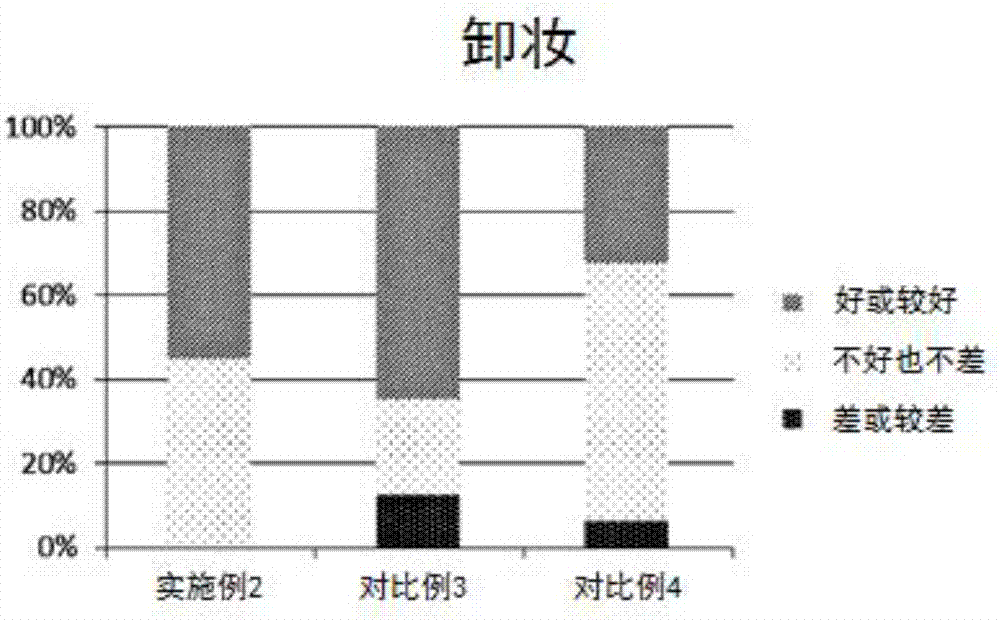

[0113] The makeup remover evaluation result of embodiment 2, comparative example 3,4 is as figure 2 shown.

[0114] The number of answers of "good" and "good" is totaled, and the number of answers of "poor" and "poor" is also totaled, and the ratio of the number of answers is shown in a graph. In Comparative Examples 3 and 4 not containing component D, the ratios of poor or poor makeup removal were 12.9% and 6.5%, respectively, and Example 2 was 0%.

[0115] The method of use by professional judges is not limited, and it is generally expected that water will be mixed during makeup removal. It was confirmed that Example 2, which has a high solubilizing power of water, can stably exert the effect of makeup removal.

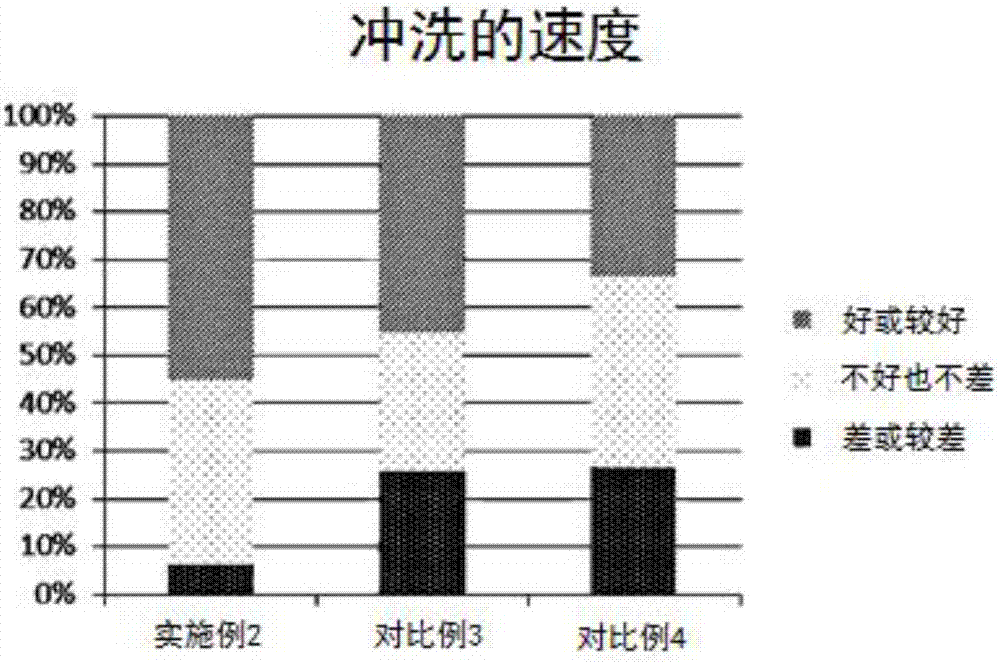

[0116] The evaluation result of the flushing speed of embodiment 2, comparative example 3,4 is as image 3 shown.

[0117] The number of answers of "good" and "good" is totaled, and the number of answers of "poor" and "poor" is also totaled, and the ratio of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com