A constant ratio production system and process of heat-curing furan resin

A furan resin and production system technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of rough proportioning and uneven mixing, and achieve the effect of improving mixing uniformity and accuracy of proportioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

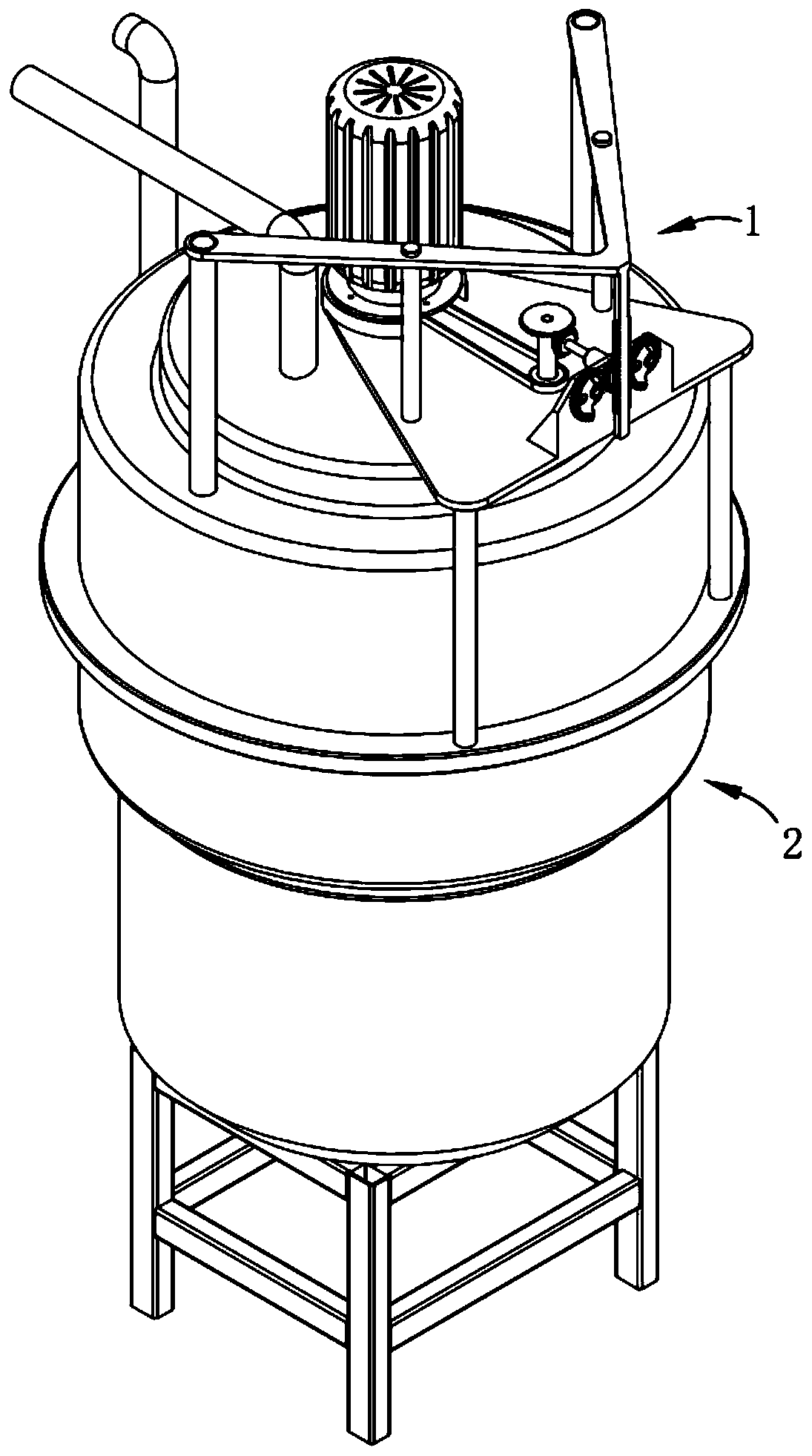

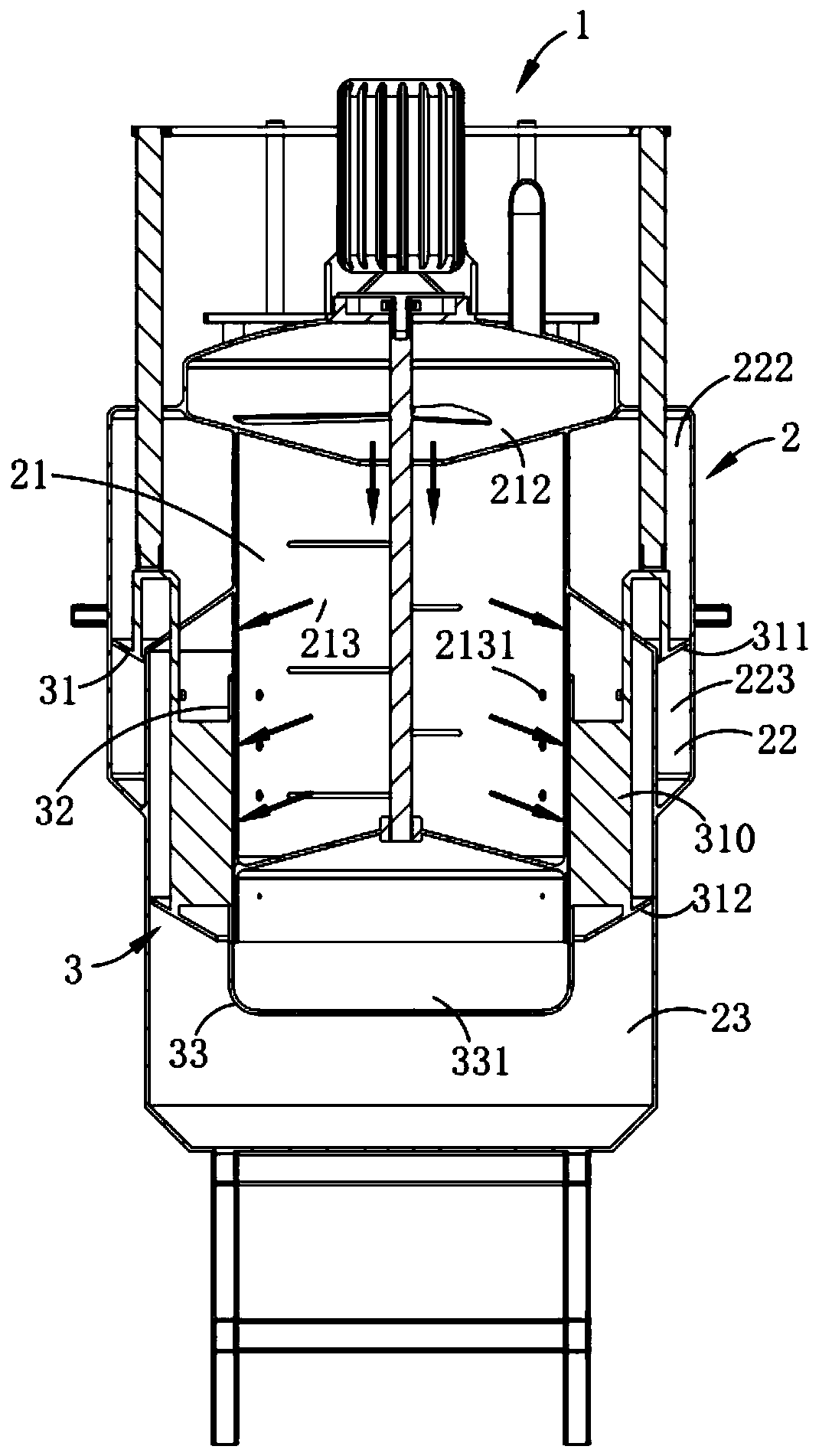

[0044] Such as figure 1 , 2 , 3, 4, 5 and 6, a heat-cured furan resin ratio production system, comprising a power mechanism 1, comprising:

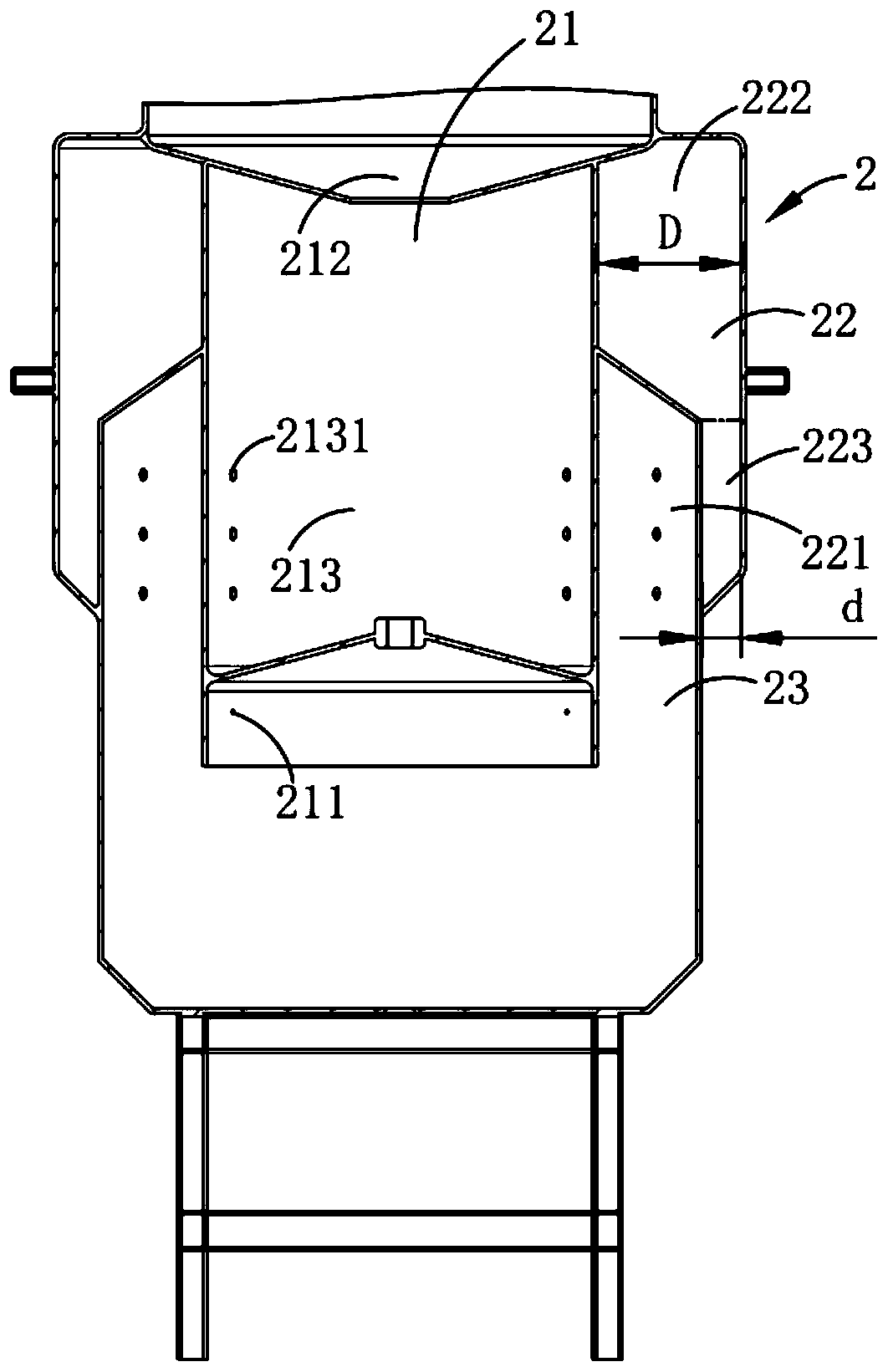

[0045] A buffer mechanism 2, the buffer mechanism 2 includes a main material buffer bin 21, an auxiliary material temporary storage bin 22 and a mixing space 23 arranged between them;

[0046] The output mechanism 3, the output mechanism 3 includes a compression assembly 31, a barrier assembly 32 connected to the compression assembly 31 and cooperatingly arranged on the main material buffe...

Embodiment 2

[0053] Such as figure 2 , 4 and 6, wherein the same or corresponding parts as in the first embodiment adopt the corresponding reference numerals with the first embodiment, for the sake of simplicity, only the differences from the first embodiment are described below; the second embodiment is different from the first embodiment The difference is that: the catalyst output assembly 33 includes a catalyst buffer chamber 331 arranged below the main material buffer chamber 21, a plurality of Catalyst spout 332, the catalyst spout 332 is intermittently connected with the through hole 211 fixedly arranged below the main material buffer bin 21, the catalyst spout 332, the introduction part 221 and the output part 321 are in the same vertical plane In this embodiment, there are preferably three catalyst injection ports 332 and through holes 211 , which are uniformly distributed along the circumferential direction of the catalyst buffer chamber 331 and the main material buffer bin 21 ....

Embodiment 3

[0058] Such as image 3 and 9 As shown, the parts identical or corresponding to those in the second embodiment adopt the reference numerals corresponding to the second embodiment. For the sake of simplicity, only the differences between the second embodiment and the second embodiment are described below; the difference between the third embodiment and the second embodiment The difference is that the output mechanism 3 also includes a main material mixing assembly 34 that is rotatably arranged inside the main material buffer bin 21, and the main material mixing assembly 34 includes a first stirring part 341 and is located below the first stirring part 341. The second stirring part 342, the first stirring part 341 is provided with an oblique propeller structure, the second stirring part 342 includes a number of stirring rods 3421 uniformly distributed around its axis, and between adjacent stirring rods 3421 The upper and lower phases are staggered; a plurality of stirring rods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com