Floating grinding device for multi-specification castings

A multi-specification, casting technology, applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine, etc., can solve the problems of dangerous operating environment, low efficiency, inconvenient production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

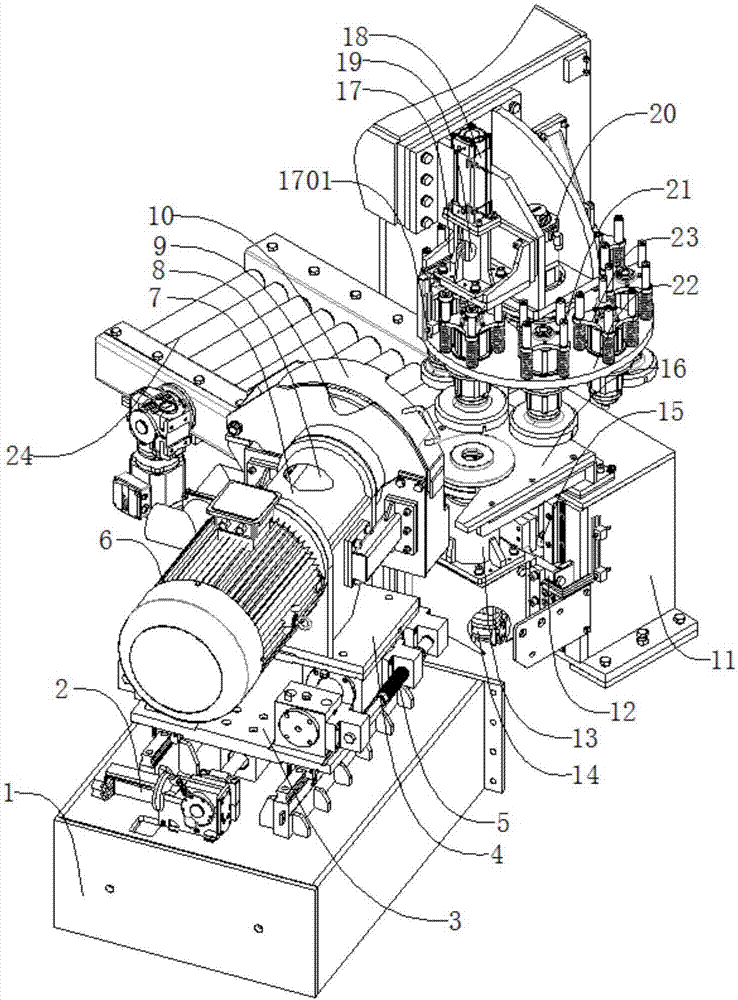

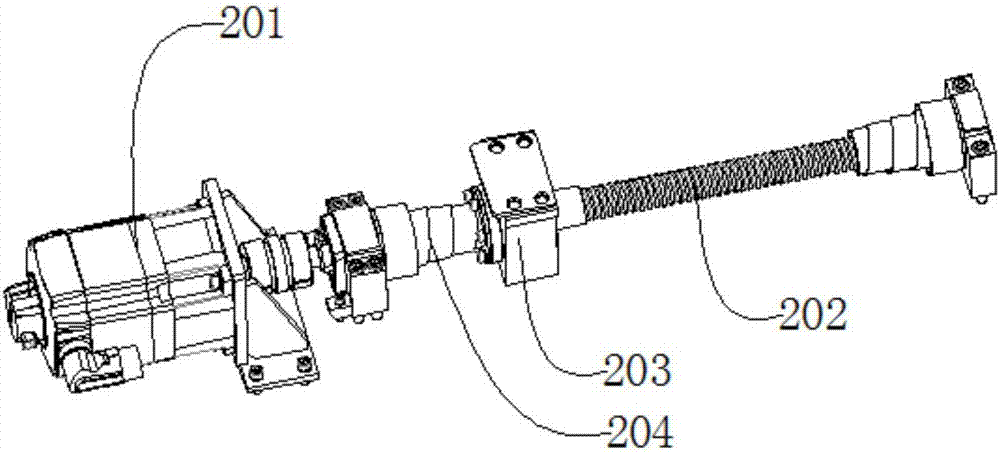

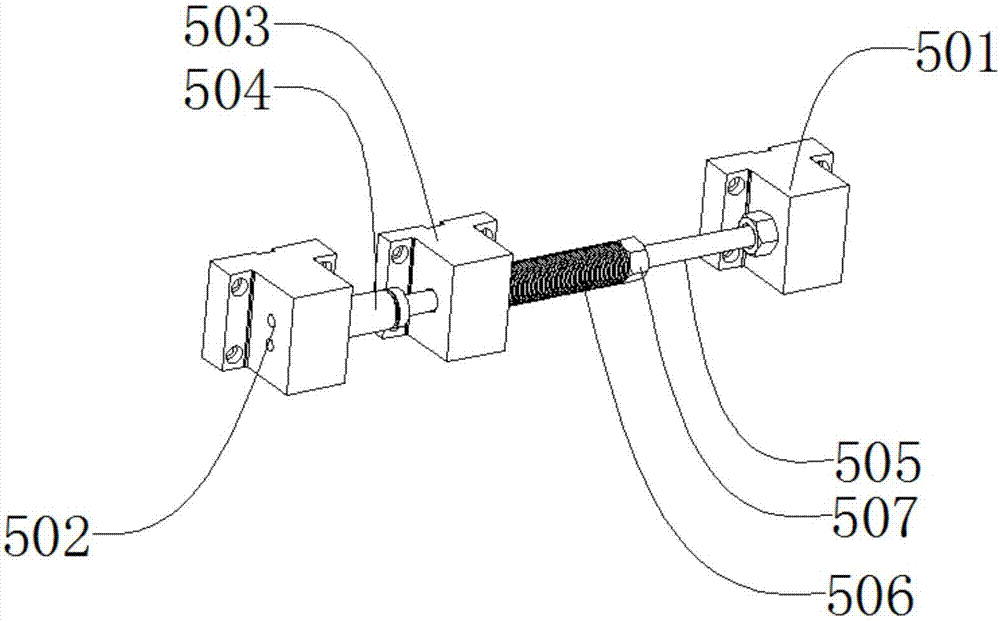

[0025] Such as figure 1 , figure 2 , image 3 ,Such as Figure 4 , Figure 5 , Figure 6 ,Such as Figure 7 , Figure 8As shown, a multi-standard casting floating grinding device includes a first frame 1, a feed mechanism 2, a lower seat 3, an upper slide seat 4, an elastic mechanism 5, a main motor 6, a rotating shaft box 7, a first rotating shaft 8, Grinding wheel 9, dust suction mechanism 10, second frame 11, sliding plate 12, floating mechanism 13, speed regulating motor 14, lifting cylinder 15, transition plate 16, guide seat 17, downward pressure cylinder 18, pressure rod 19, servo Motor 20, reducer 21, wheel disc 22, platen mechanism 23, V-belt conveyor 24, described feed mechanism 2 is positioned at the first frame 1 upper end, described feed mechanism 2 and the first frame 1 is connected by bolts, and the sliding seat 3 is located at the upper end of the feeding mechanism 2 and at the upper end of the first frame 1, and the sliding seat 3 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com