Flexible epoxy resin adhesive capable of being cured under room temperature

A flexible epoxy resin and room temperature curing technology, which is applied in the field of epoxy resin adhesives and room temperature curing flexible epoxy resin adhesives, can solve the problems of poor flexibility, easy cracking during use, poor peel strength and impact resistance, etc., to achieve Improved impact resistance, good adhesion, good flexibility and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

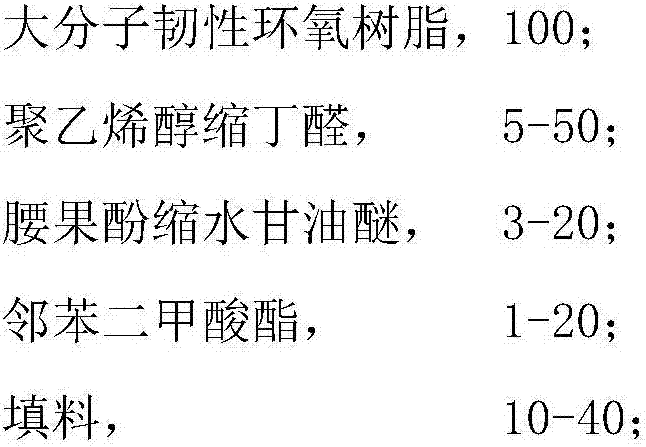

Method used

Image

Examples

Embodiment 1

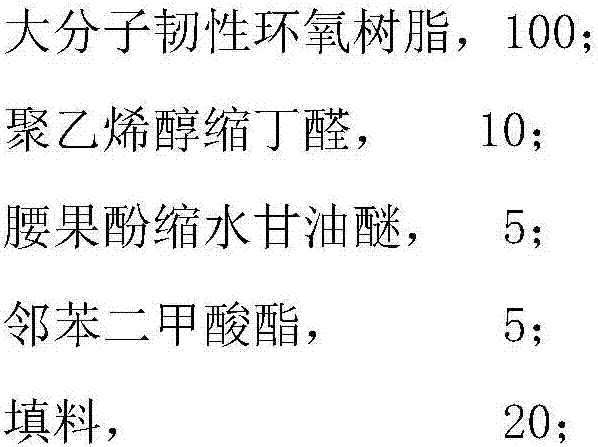

[0023] Component A: 100g epoxy resin, 10g polyvinyl butyral, 5g cardanol glycidyl ether, 5g phthalate, 20g filler. Component B: 100 grams of polyamide 650, 3 grams of KH560, 3 grams of DMP-30.

[0024] In the preparation process of the present invention, each raw material is firstly weighed according to parts by weight, and then put into a container and mixed uniformly for use. The shearing strength of this embodiment can reach 30MPa, and the peeling strength is above 42MPa.

Embodiment 2

[0026] Component A: 100g epoxy resin, 15g polyvinyl butyral, 3g cardanol glycidyl ether, 8g phthalate, 15g filler. Component B: 100 grams of polyamide 650, 3 grams of KH560, 3 grams of DMP-30.

[0027] In the preparation process of the present invention, each raw material is firstly weighed according to parts by weight, and then put into a container and mixed uniformly for use. The shearing strength of this embodiment can reach 32MPa, and the peeling strength is above 45MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com