Dual-cavity type electric energy storage heating system

A heat supply system and heat storage furnace technology, which is applied in the field of electric heating equipment, can solve the problems of poor heat preservation effect, small heat storage, and low heat storage temperature, and achieve the effects of enhanced heat preservation effect, controllable power, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described below.

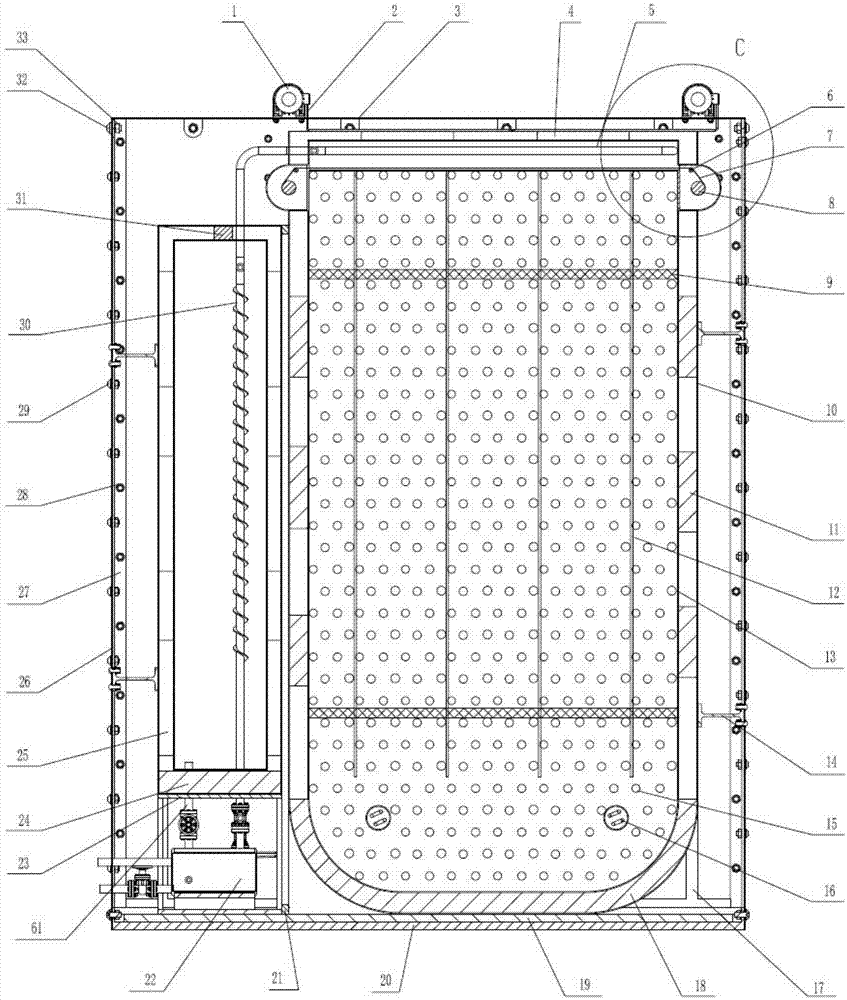

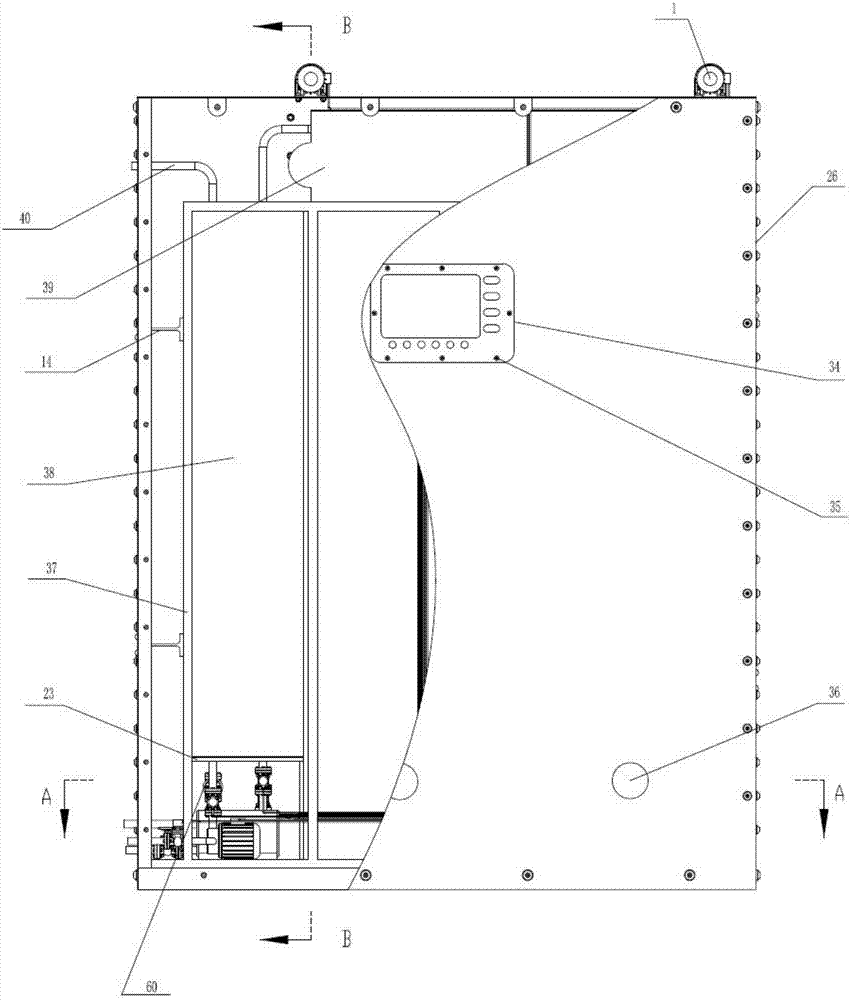

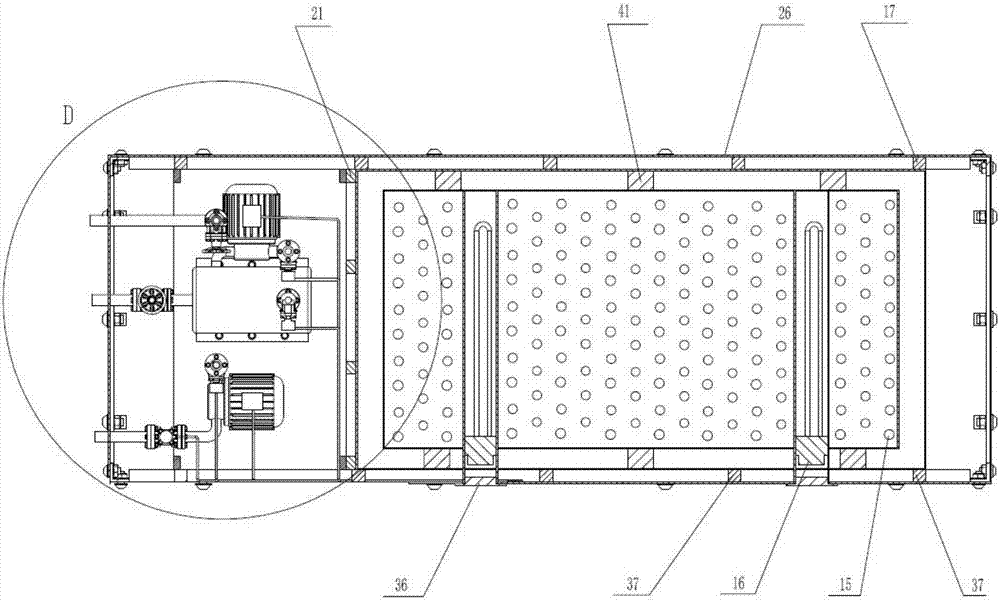

[0028] like figure 1 , figure 2 As shown, the double-chamber electric energy storage heating system includes a box shell 26 with a control panel 34, the control panel 34 is fixed on the outer surface of the box shell 26 by the third round head screw 35, and the box shell 26 The top is affixed to the upper cover 3 of the box body through the second round head screw 32 and the second welded hexagon nut 33. The bottom cover 20 of the box body is arranged at the bottom of the box body shell 26, and the outside of the regenerative furnace is arranged inside the box body shell 26. Liner 10, a regenerative furnace liner 13 is set inside the regenerative furnace outer liner 10, a hollow layer is formed between the regenerative furnace outer liner 10 and the regenerative furnace liner 13, and the first asbestos strip is installed on the top of the hollow layer 4. Install the second asbestos strip 11 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com