Vehicle-mounted mobile constant-temperature liquid cooling source device

A technology of cold source device and constant temperature liquid, used in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of difficult troubleshooting, unfavorable factors in the service life of compressors, and large space occupation, so as to reduce energy consumption and compression. machine failure rate, improve transportation reliability, easy maintenance and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

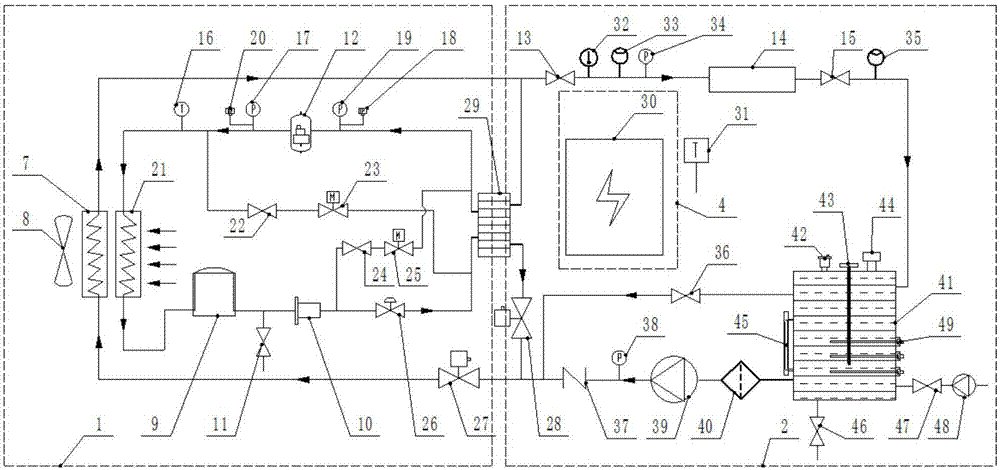

[0026] As shown in the figure, a vehicle-mounted mobile constant temperature liquid cooling source device includes a refrigeration unit 1, a water cooling unit 2, a frame 3 and an electrical control unit 4, and the refrigeration unit 1, the water cooling unit 2 and the electrical control unit 4 are arranged in the frame 3 , the frame 3 is placed in the vehicle-mounted shelter, and shock absorbers are arranged at the bottom and back of the frame 3 .

[0027] The refrigeration unit 1 includes two refrigeration routes to ensure that the water cooling unit 1 outputs constant-temperature refrigerant water, namely, the route for cooling and outputting refrigerant water through the compressor 12 in cooperation with the plate evaporator 29 and the route for cooling and outputting refrigerant water directly through the conventional heat exchanger 7 using ambient air cooling route. The route of the compressor 12 and the plate evaporator 29 in the refrigeration unit 1 is controlled by th...

Embodiment 2

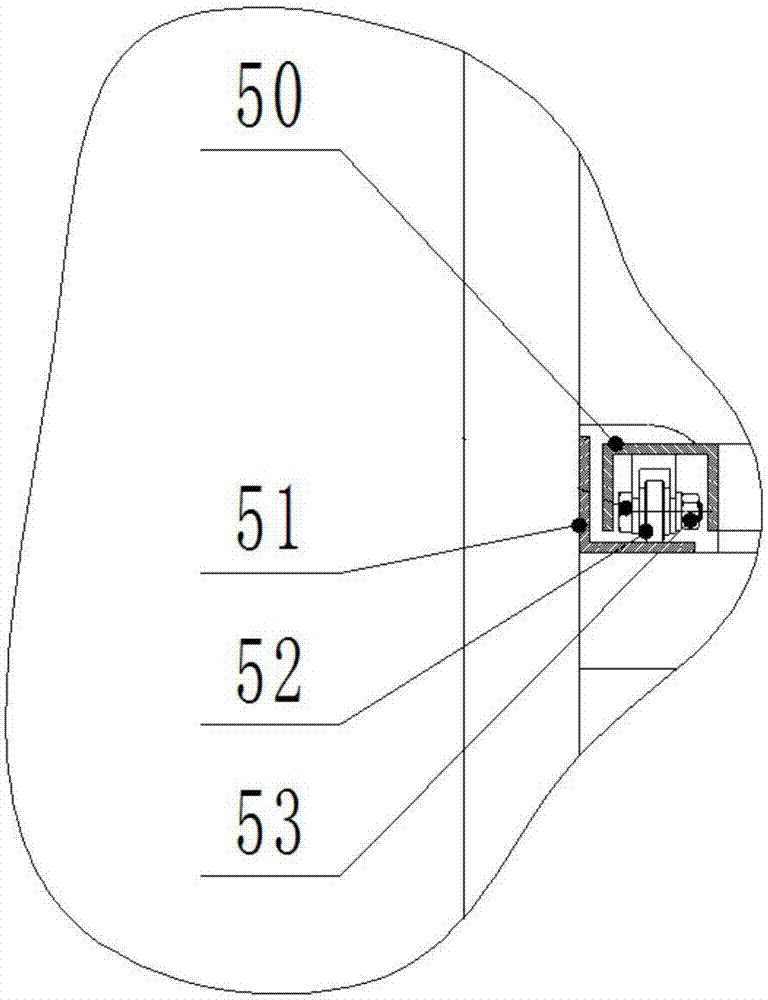

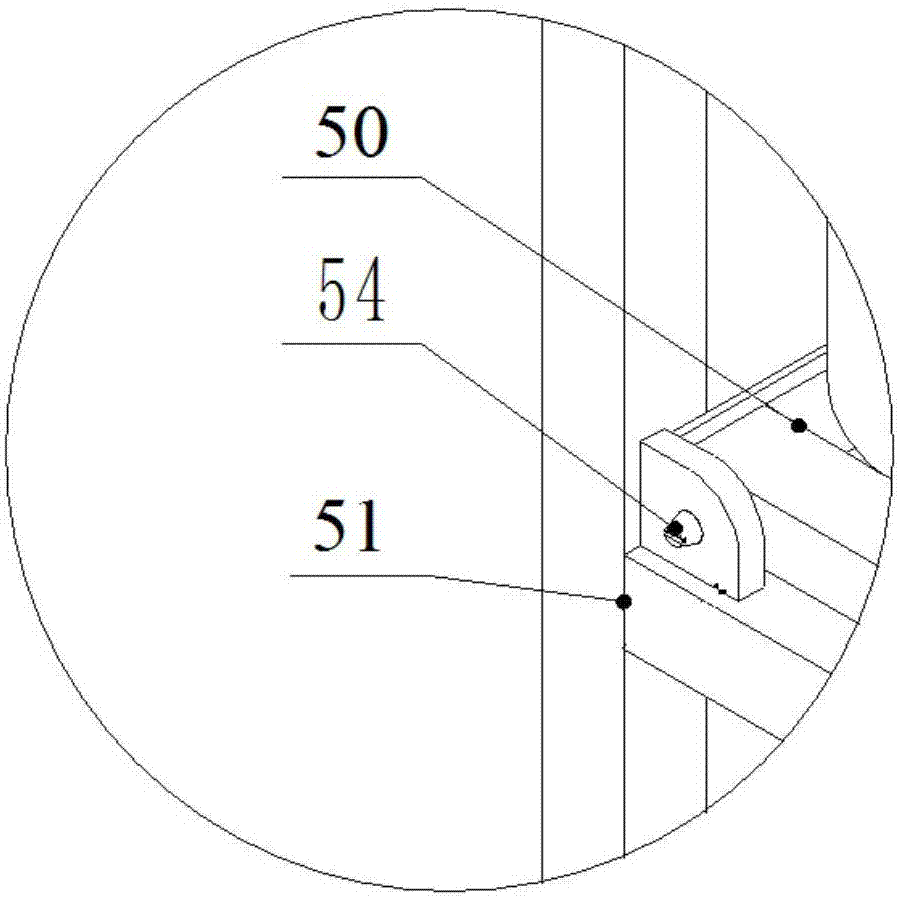

[0032] Embodiment 2 On the basis of Embodiment 1, a frame beam 51 is set in the middle of the frame 3, and the frame 3 is divided into upper and lower parts. The refrigeration unit 1 is installed on one side of the upper part of the frame 3, and the electrical appliance is installed on the other side of the upper part of the frame 3. The control unit 4, the water cooling unit 2 is installed on the lower part of the frame 3. During the installation process, the refrigeration unit 1 and the water-cooling unit 2 are placed on two independent frame modules respectively, and the frame module beam 50 is set at the bottom of the two frame modules, and a positioning pin 54 is set at one end of the frame module beam 50, and a locking block is set at the other end 62. Roller installation shaft 55 and roller 52 are installed at the bottom. The roller 52 is installed in the installation shaft 55 through the nut 53. The two frame modules are respectively pushed to the appropriate position o...

Embodiment 3

[0034] Embodiment 3 On the basis of Embodiments 1 and 2, shock absorbers are provided on the bottom and back of the frame 3 , and the liquid cooling source frame 3 is connected to the vehicle-mounted shelter 6 through the shock absorber 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com