Control system and method for condenser and water chilling unit

A control system and chiller technology, applied in the condenser control system and chiller field, can solve the problems of high operating cost, complex control system structure, poor control effect, etc., and achieve the effect of saving operating cost and improving capacity and energy efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

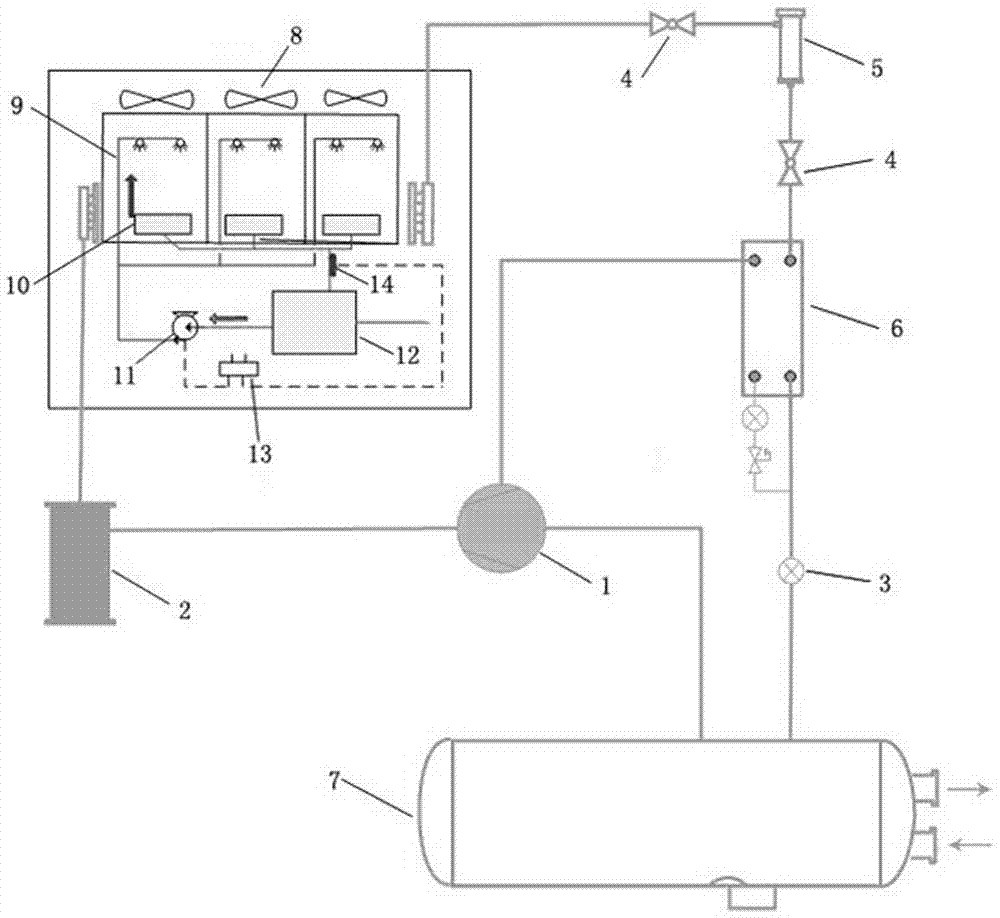

[0029] Such as figure 1 As shown, the evaporative cooling chiller includes a compressor 1 , an oil separator 2 , a condenser 9 and an expansion valve 3 connected in sequence. A dry filter 5 and an economizer 6 are also arranged between the condenser and the expansion valve. Refrigerant flow direction:

[0030] Compressor 1—oil separator 2—condenser 9—ball valve 4—dry filter 5—ball valve 4—economizer 6—expansion valve 3—shell and tube evaporator 7—compressor 1.

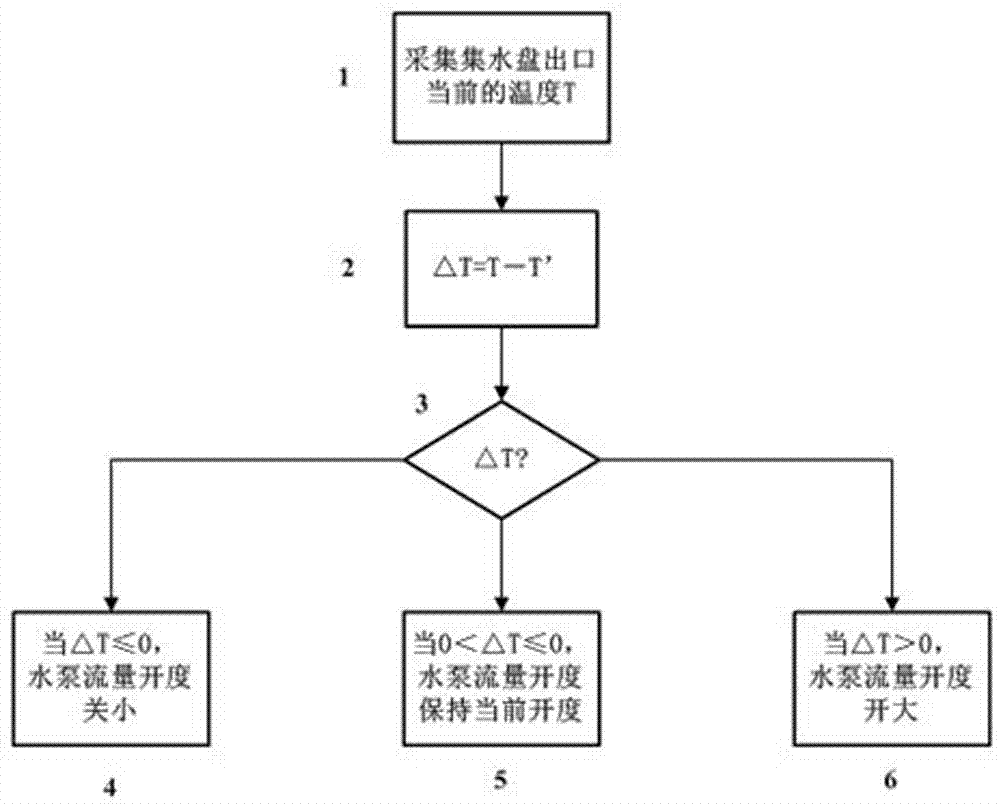

[0031] The condenser 9 adopts a tower-type evaporative condenser. When the water supply is insufficient, the temperature of the water coming out of the water collecting tray 10 will increase, and the outlet water temperature can be effectively reduced by appropriately increasing the cooling water supply.

[0032] In this embodiment, the condenser 9 includes three spray cooling towers, and a water c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com