Optimized slow slag cooling field automatic spraying system

An automatic spraying and slow cooling technology, applied in general control systems, control/regulation systems, comprehensive factory control, etc., can solve problems such as increased engineering costs, difficulties, inconveniences, etc., to reduce energy consumption, improve efficiency, and ensure operations. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

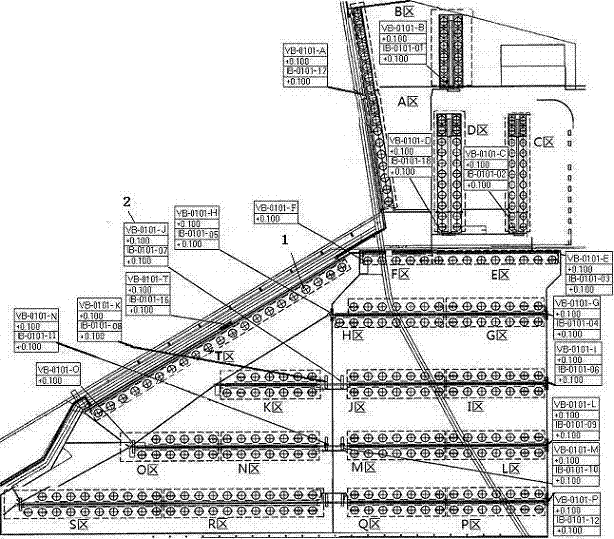

[0019] Such as figure 2 As shown, there are a total of 302 slag bags in the slag slow cooling field, correspondingly there are 302 pneumatic cut-off diaphragm valves, which are divided into 20 groups, and data acquisition devices are installed near each valve group on site. Each data acquisition device can access about 20 valve measuring point signals, and the signal type is DI or DO. Corresponding to the recombination of each valve group, configure the bus module, a total of 17 sets of signal acquisition devices, the signal acquisition devices are set in the communication box, numbered IB-0101-01~17. The positions of each valve, valve group box and communication box are as follows: figure 2 shown. The specific configuration is as follows:

[0020]

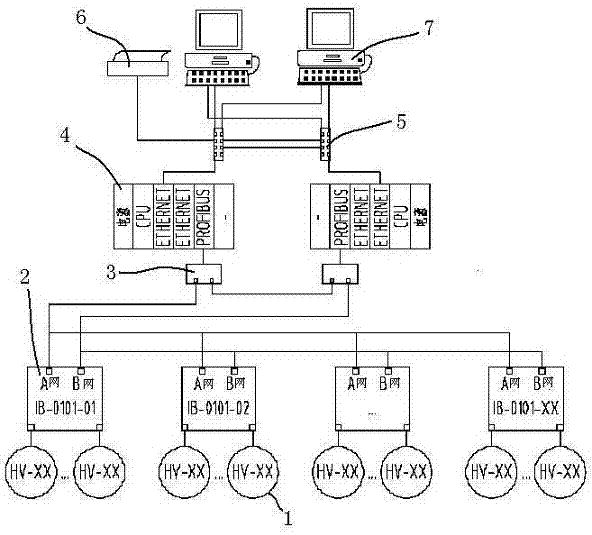

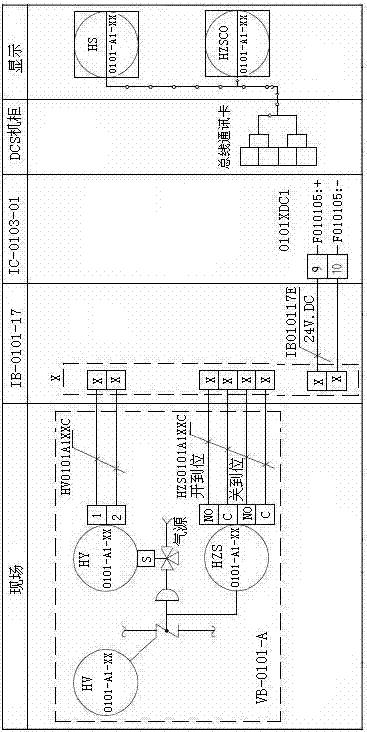

[0021] The network configuration and the internal configuration diagram of the valve group are as follows: image 3 shown. Configure dual-network communication interfaces on the acquisition device to form A-network and B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com