Method for manufacturing screen picture with laser

A screen and graphics technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of low screen resolution, screen surface pollution, and difficult line width, etc., to improve graphics accuracy and production rate, improve dimensional accuracy, and reduce the effect of screen waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0013] This embodiment provides a method for making screen graphics by laser, which is specifically carried out in the following steps: 1. Coat the screen that has been stretched with non-photosensitive glue, and then dry it; 2. After the screen is dried, , take out the screen and place it on the picosecond laser engraving processing platform; 3. Import the graphics parameters required by the customer into the laser engraving software, and perform laser graphics engraving operations until the screen graphics are completed; 4. After the finished The screen is cleaned and dried, and the screen production is completed.

[0014] The coating thickness of the non-photosensitive glue described in the first step is 5-100 μm.

[0015] In step 2, the picosecond laser wavelength of the picosecond laser engraving processing platform is 532-1064nm.

[0016] The line width of the screen pattern described in step 3 is 5-100 μm.

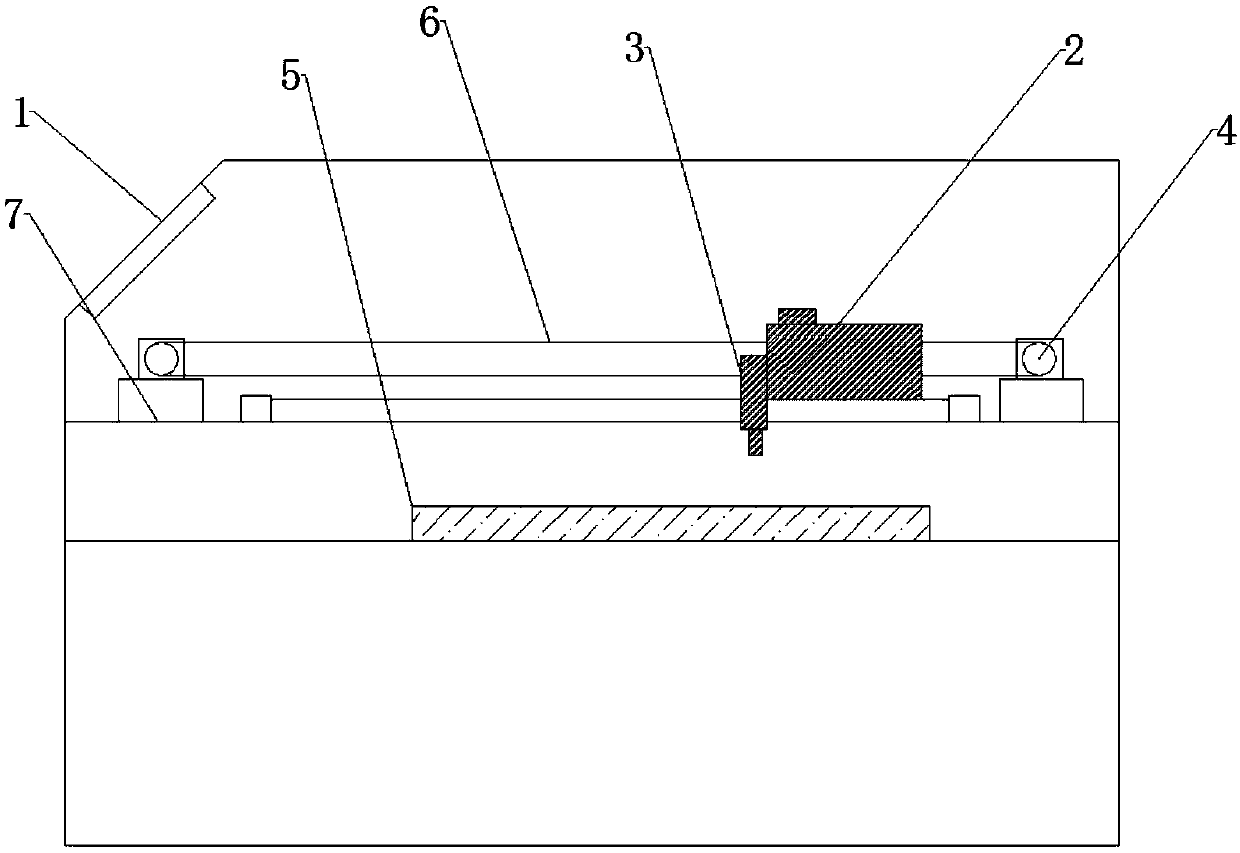

[0017] Such as figure 1 As shown, the picosecond laser engr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com