Method for comprehensive utilization of cyanide tailings and device

A technology for cyaniding tailings and tailings, which is applied in the direction of chemical instruments and methods, sulfur compounds, nitrogen and non-metallic compounds, etc., can solve the problems of low recycling rate of cyanided tailings and non-recycling, and achieve favorable Purification and reuse, enhanced strength, high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

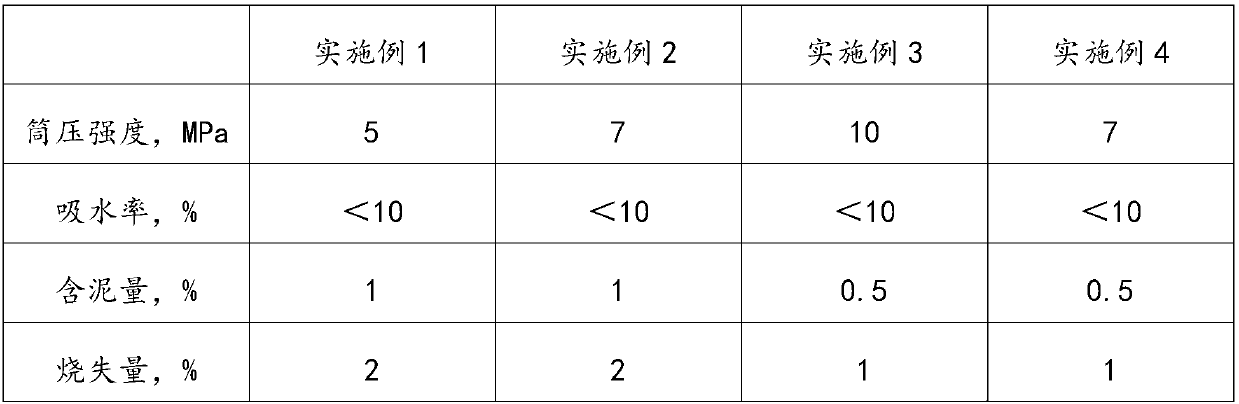

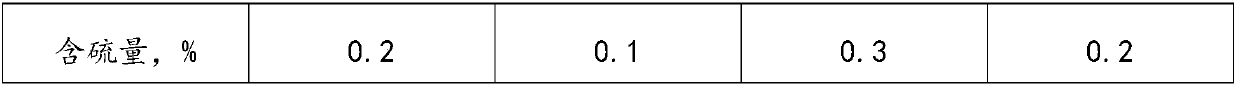

Embodiment 1

[0059] This embodiment provides a method for comprehensive utilization of cyanide tailings, comprising the following steps:

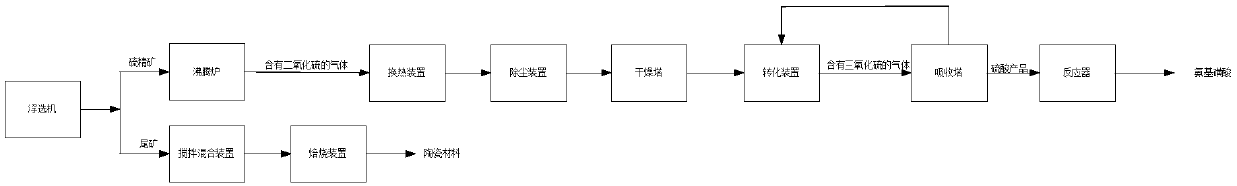

[0060] Such as figure 1 as shown,

[0061] (1) mixing the cyanide tailings with water to prepare the first slurry whose mass concentration of the cyanide tailings is 40%;

[0062] Adding concentrated sulfuric acid with a mass concentration of 98% to the first slurry, adjusting the pH value of the first slurry to 4, and then adding water to dilute it into a second slurry with a mass concentration of cyanidation tailings of 30%;

[0063] The second slurry is transported to the flotation machine, and the amount of 400g butyl sodium xanthate is added to the second slurry per ton, and butyl sodium xanthate is added to the second slurry; 50g No. 2 oil is added to the second slurry per ton The amount, add No. 2 oil in the second slurry;

[0064] Use an air pump to ventilate the second slurry, and the flotation machine starts screening to obtain sulfur conce...

Embodiment 2

[0082] This embodiment provides a method for comprehensive utilization of cyanide tailings, comprising the following steps:

[0083] (1) mixing the cyanide tailings with water to prepare the first slurry whose mass concentration of the cyanide tailings is 50%;

[0084] Adding concentrated sulfuric acid with a mass concentration of 98% to the first slurry, adjusting the pH value of the first slurry to 5, and then adding water to dilute it into a second slurry with a mass concentration of cyanidation tailings of 30%;

[0085] Add 500g butyl sodium xanthate to the second slurry in the amount of 500g per ton of the second slurry, add butyl sodium xanthate to the second slurry; add 60g No. 2 oil to the second slurry in the amount of No. 2 Oil;

[0086] Ventilating into the second slurry, flotation to obtain sulfur concentrate with a sulfur content greater than or equal to 46% and tailings with a sulfur content less than 46%;

[0087] One-stage screening of tailings and three-stag...

Embodiment 3

[0105] This embodiment provides a method for comprehensive utilization of cyanide tailings, comprising the following steps:

[0106] (1) mixing the cyanide tailings with water to prepare the first slurry whose mass concentration of the cyanide tailings is 60%;

[0107] Adding concentrated sulfuric acid with a mass concentration of 98% to the first slurry, adjusting the pH value of the first slurry to 5, and then adding water to dilute it into a second slurry with a mass concentration of cyanidation tailings of 30%;

[0108] Add 450g butyl sodium xanthate to the second slurry in the amount of 450g per ton of the second slurry, add butyl sodium xanthate to the second slurry; add 55g No. 2 oil to the second slurry in the amount of 2 Oil;

[0109] Ventilating into the second slurry, flotation to obtain sulfur concentrate with a sulfur content greater than or equal to 46% and tailings with a sulfur content less than 46%;

[0110] (2) Preparation of sulfuric acid product:

[0111...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com