Removal method of pentone in C5 fraction

A C5 fraction, medium isoprene technology, applied in chemical instruments and methods, hydrocarbon, hydrocarbon purification/separation, etc., can solve the problem of increasing energy consumption, reducing isoprene yield, and improving operation severity and other problems, to achieve the effect of reducing energy consumption, reducing operational severity, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

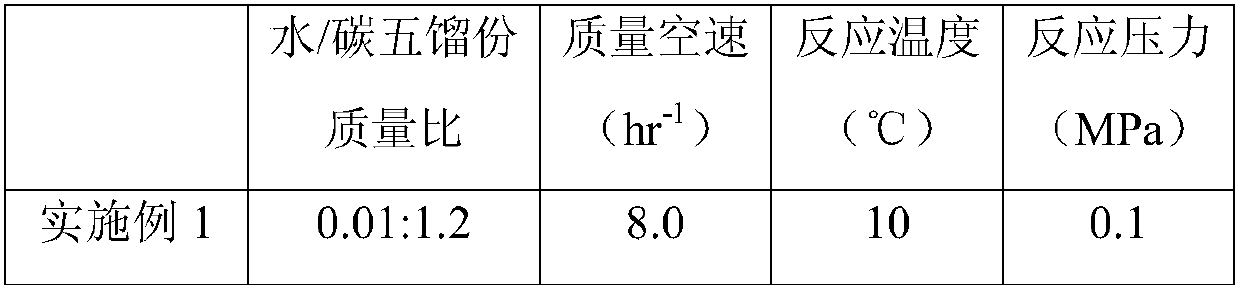

[0022] 1. Raw material of C5 distillate

[0023] The C5 fractions used in Examples 1 to 10 come from a part of the material produced by the C5 separation device when producing isoprene. The components of the C5 fraction are shown in Table 1.

[0024] Table 1. C5 Fraction Composition

[0025] components

C5 fraction

Total C4,%

0.02

3-Methylbutene-1,%

0.01

1.4-Pentadiene,%

0.02

2-Butyne,%

0.17

Isopentenyne,%

2.25

2-Methylbutene-1,%

0.02

Isoprene,%

96.56

2-Methylbutene-2,%

0.06

0.00

0.00

Other C5,%

0.00

0.35

pH

10

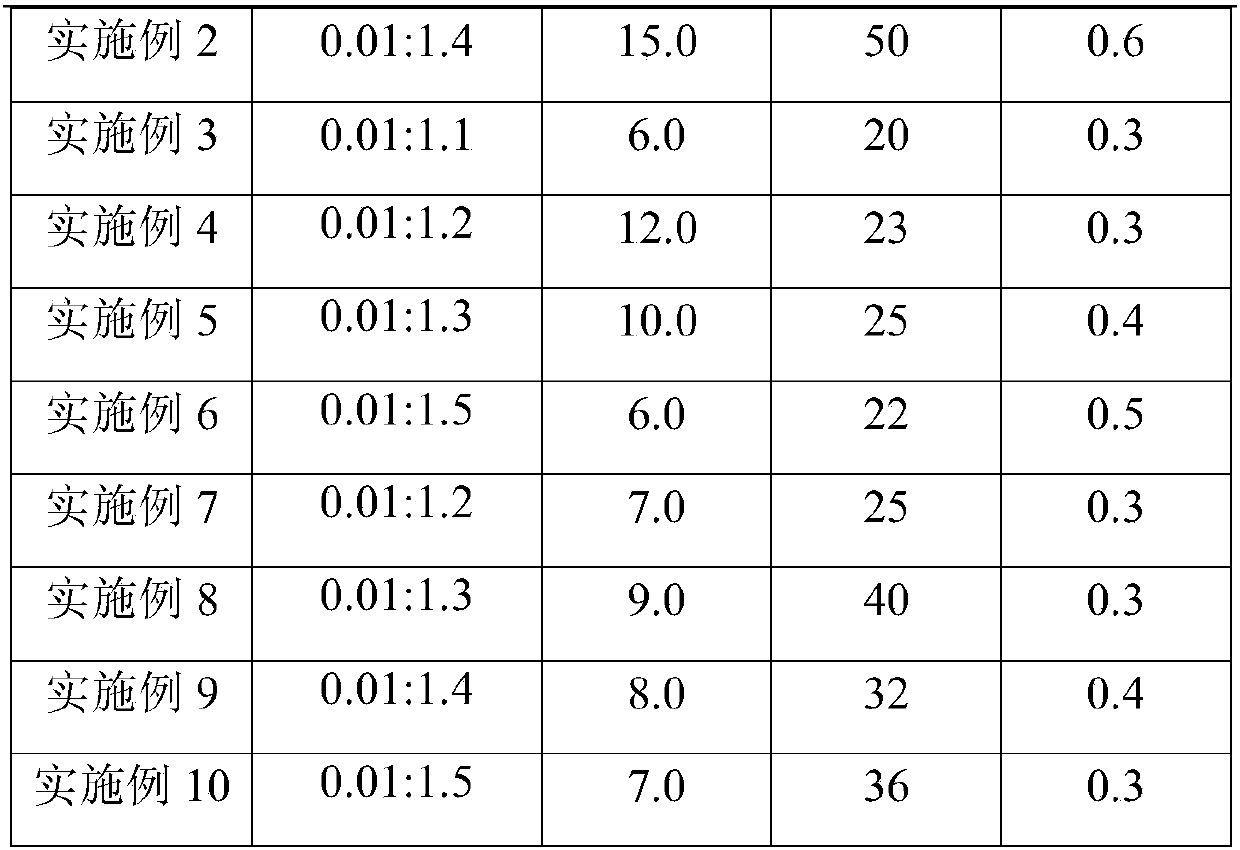

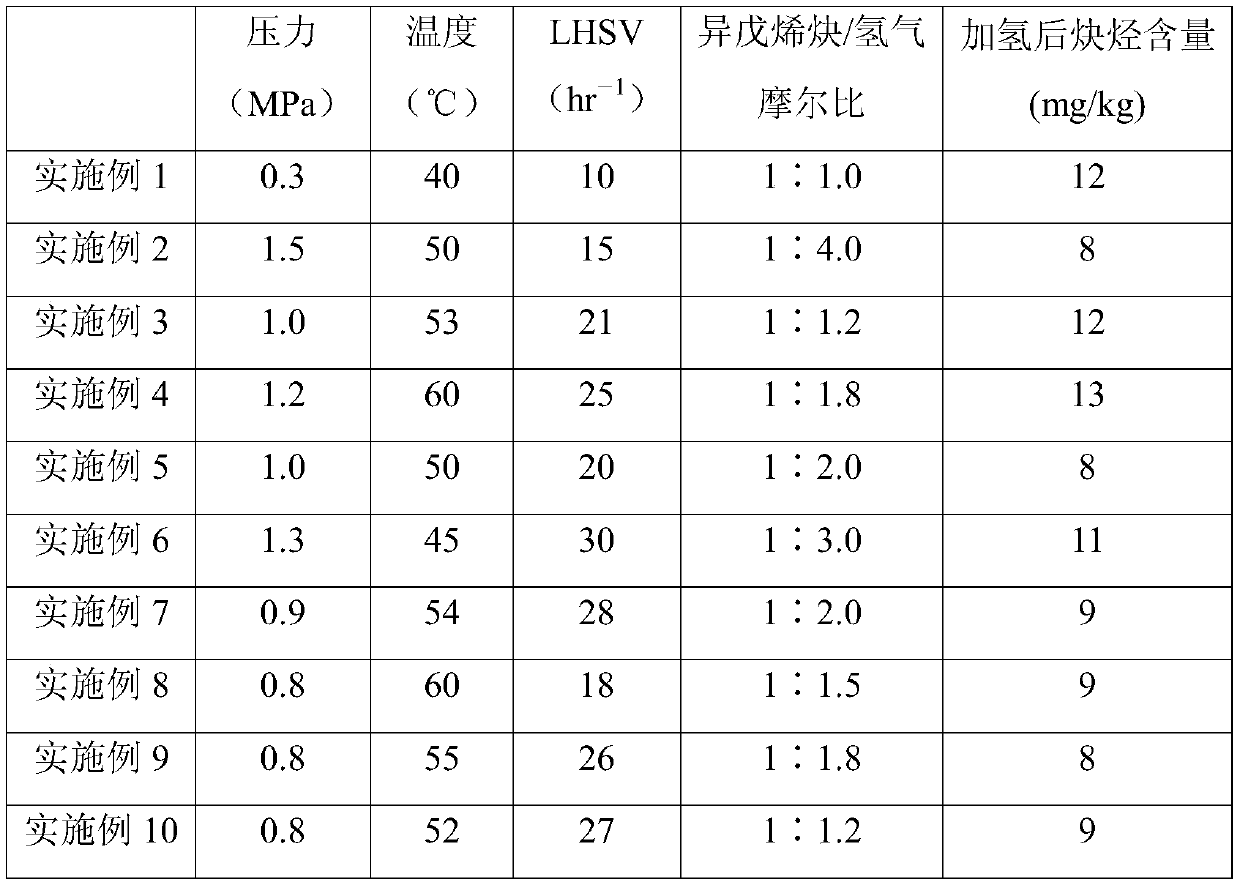

[0026] 2. Dimethylamine removal of C5 fraction

[0027] The size of the water washing tower for removing dimethylamine from the carbon five fraction is It is carried out in a stainless steel tube, and 100 grams of spherical sulfonic acid-based cation exchange resin cataly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com