High-performance water-based polymer drilling fluid system

A water-based polymer, high-performance technology, applied in the field of oil drilling drilling fluids, can solve problems such as weakening of inhibition performance, and achieve the effects of reducing swelling and dispersion, strengthening wellbore collapse, and inhibiting wellbore collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

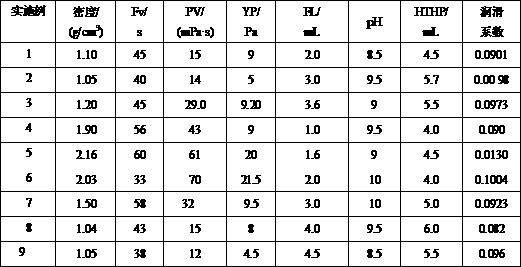

Examples

Embodiment 1

[0018] Example 1: 3% bentonite + 0.6% NH-1 + 0.2% cationic polyacrylamide (cationic degree 3.5%, number average molecular weight 500,000, cation is DA) + 0.5% polyanionic cellulose + 5% cationic glycoside + 0.2 %Xanthan Gum+15%BaSO 4 .

Embodiment 2

[0019] Example 2: 1.5% bentonite + 0.5% polyamine inhibitor + 0.3% cationic polyacrylamide (cationic degree 5%, number average molecular weight 350,000, cation is DMDAAC) + 1.5% sodium carboxymethylcellulose + 4% NH -EPJ extreme pressure lubricant + 0.2% xanthan gum + 0.02% defoamer + 11% BaSO 4 .

Embodiment 3

[0020] Example 3: 3% bentonite + 0.8% NH-1 + 0.2% cationic polyacrylamide (cationic degree 6%, number average molecular weight 800,000, cation is DAC) + 1.0% polyanionic cellulose + 5% methyl glucoside + 0.3% xanthan gum + 0.05% defoamer + 0.3% fungicide + 20% BaSO 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com