Brown paper wick candle and preparation method thereof

A technology for oil vellum paper and candles, applied in the field of candles, can solve the problems of inability to adjust the size, no visual impact, etc., and achieve the effects of less residue, reasonable structure, and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

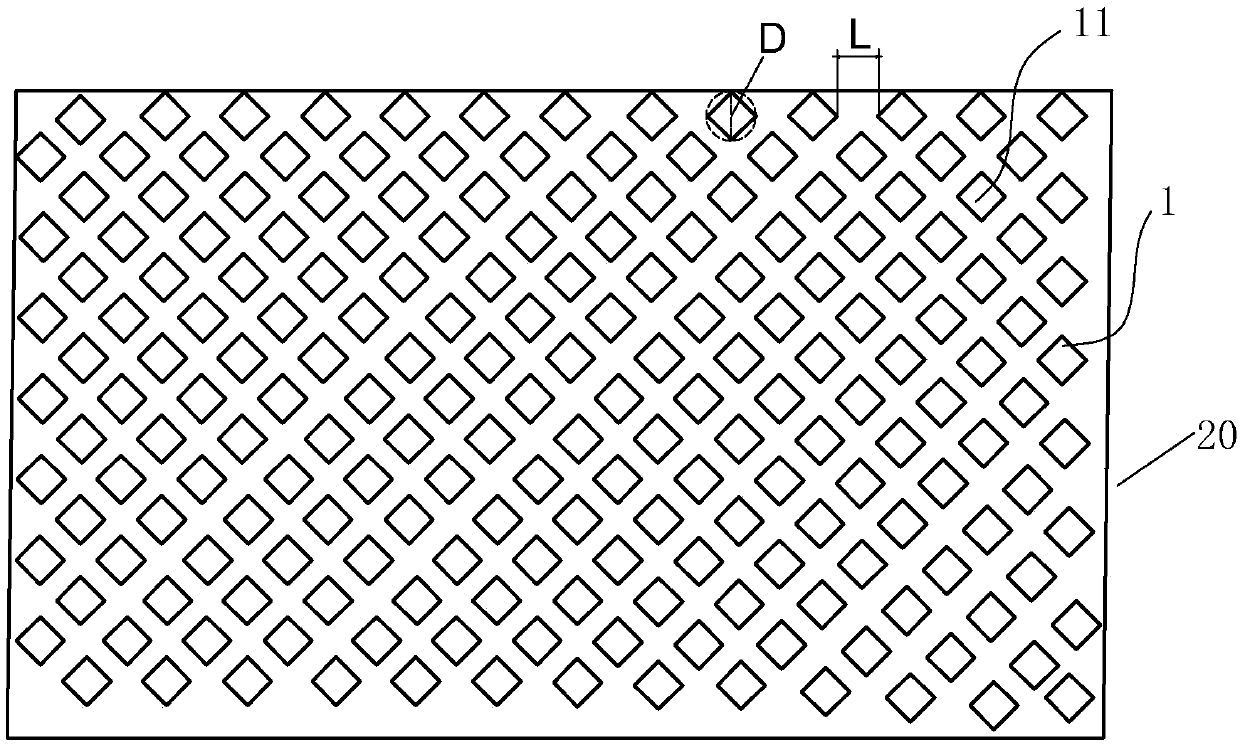

[0040] An oiled paper wick candle, which includes a candle body and a candle wick. The key point of the invention is that the candle wick is made of oiled paper wick, which is made of oiled paper 1 with a thickness of 0.8-1.2mm through plane laser cutting with hole patterns. The sheet-shaped wick 20 has a hole pattern with a hole diameter of 2-4 mm, and a parallel spacing between the holes of 2-4 mm.

[0041] The oil skin paper 1 is processed through degreasing, and the pattern with holes adopts the pattern of square holes. The square holes 11 of the square hole pattern are arranged staggered up and down, and the square holes in the upper and lower rows can be oblique lines parallel to each other. The equivalent diameter D of the square holes 11 is controlled at 2-4mm (preferably 2-3mm), and the parallel spacing of the square holes L 3 ~ 4mm, that is, the edge distance between the square hole and the square hole on the same horizontal line. Cut the oiled paper into desired sh...

Embodiment 2

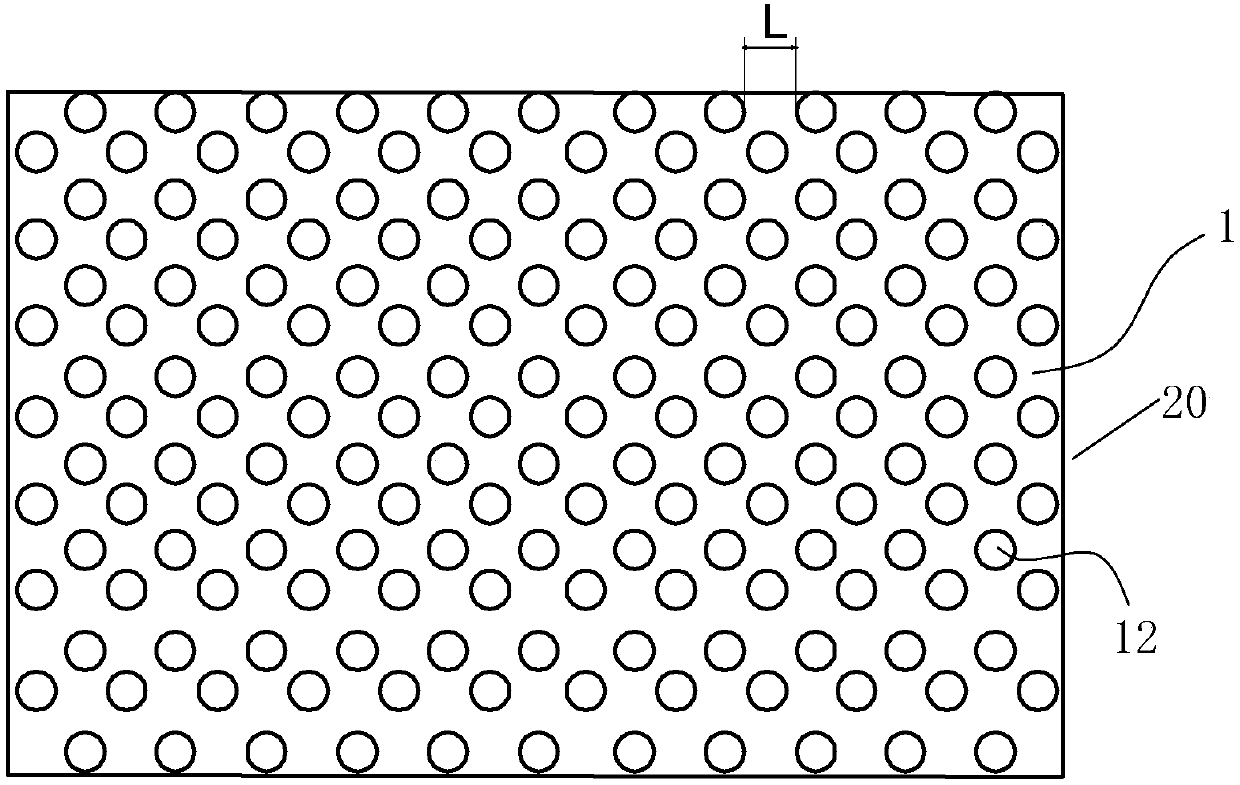

[0045] An oiled paper wick candle, including a candle body and a candle wick, the key point of the invention is that the candle wick is an oiled paper wick, which is made of oiled paper with a thickness of 0.8-1.2mm through plane laser cutting with hole patterns The sheet-shaped wick 20 has a pattern hole diameter of 2-4 mm, and a distance between the holes of 2-4 mm.

[0046] The oil skin paper 1 is processed through degreasing, and the pattern with holes adopts the pattern of round holes. The round holes 11 of the round hole pattern are arranged staggered up and down, and the round holes in the upper and lower rows can be obliquely parallel to each other. The aperture of the round holes 12 is controlled at 2-4mm (preferably 3-4mm), and the parallel spacing of the holes is 3-4mm. It is the edge distance between the circular hole and the circular hole on the same horizontal line. Cut the oiled paper into desired shaped wicks, usually rectangular sheets.

[0047] Above-mentio...

Embodiment 3

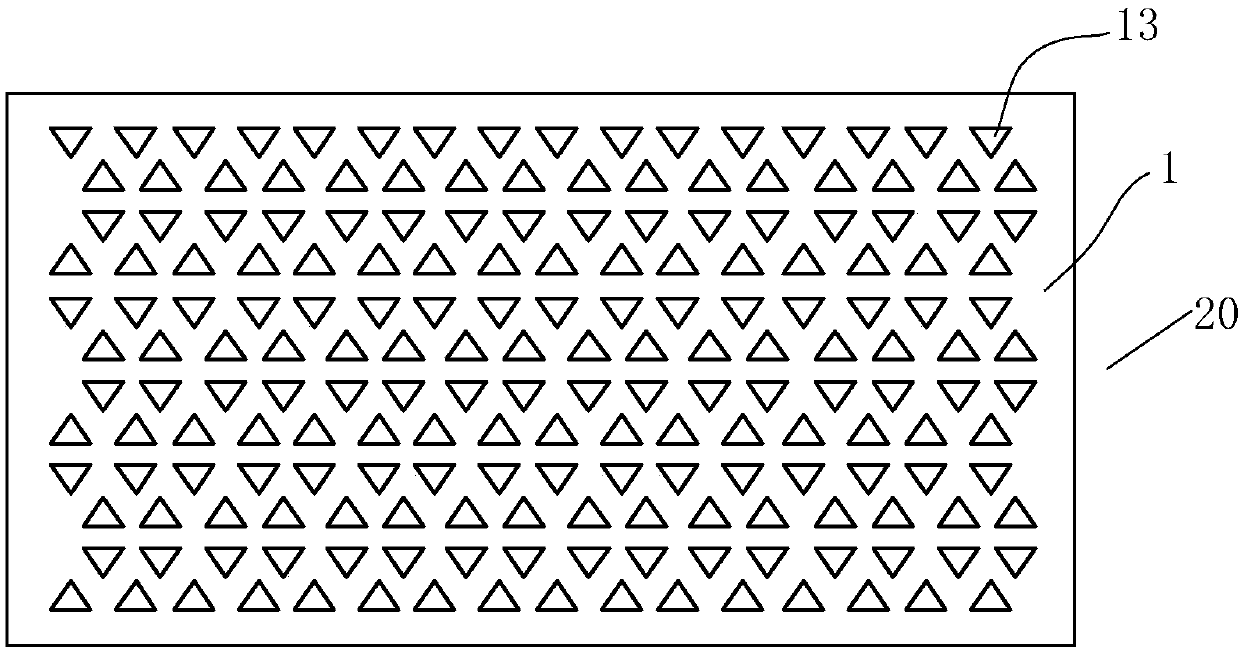

[0050] An oiled paper wick candle, including a candle body and a candle wick, the key point of the invention is that the candle wick is an oiled paper wick, which is made of oiled paper with a thickness of 0.8-1.2mm through plane laser cutting with hole patterns The sheet-shaped wick 20 has a pattern hole diameter of 2-4 mm, and a distance between the holes of 2-4 mm.

[0051] The oil skin paper 1 is degreased, and the pattern with holes adopts a triangular hole pattern. The triangular holes 13 of the triangular hole pattern are staggered up and down, and the triangular holes in the upper and lower rows can be oblique lines parallel to each other. The equivalent diameter of the triangular holes 13 is controlled at 2 to 4mm (preferably 2 to 3mm), and the parallel spacing of the triangular holes is 3mm. ~4mm is the distance between the triangular holes and the edges of the triangular holes on the same horizontal line. Cut the oiled paper into desired shaped wicks, usually recta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com