Automatic disassembly line of retired battery of electric vehicle

A technology of electric vehicles and batteries, which is applied in battery recycling, recycling technology, waste collector recycling, etc., can solve problems such as high-voltage electric shock safety, insulation leakage safety, fire prevention and explosion-proof hidden dangers, large randomness, irregularities, etc., to achieve safety Improved performance and dismantling efficiency, conducive to personnel operation, and high compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

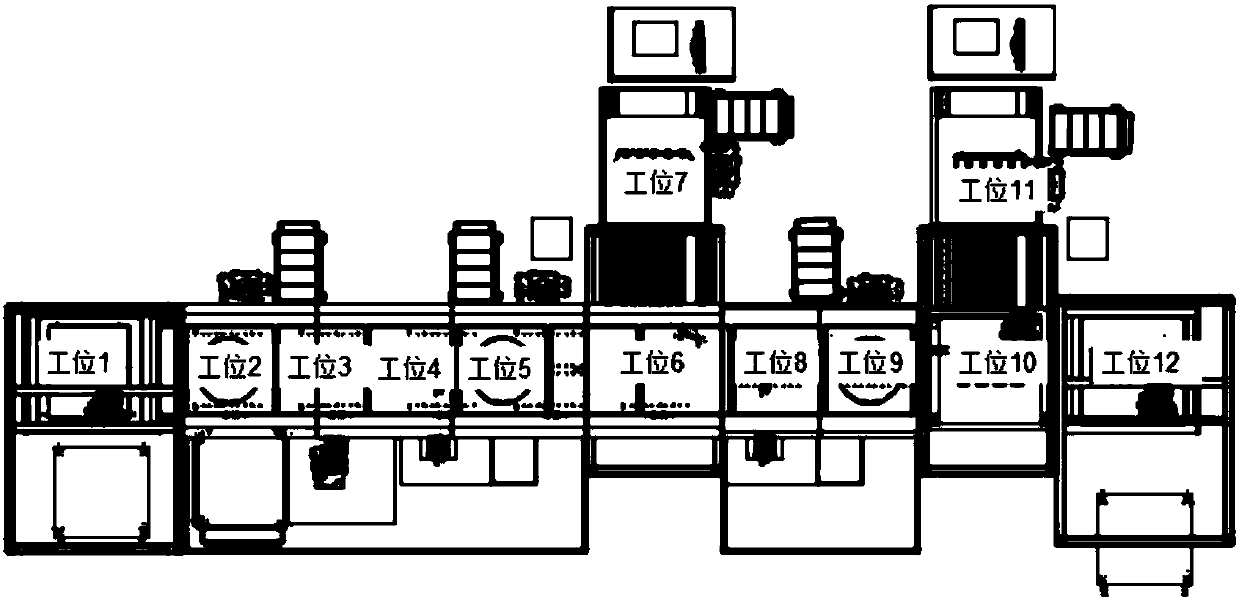

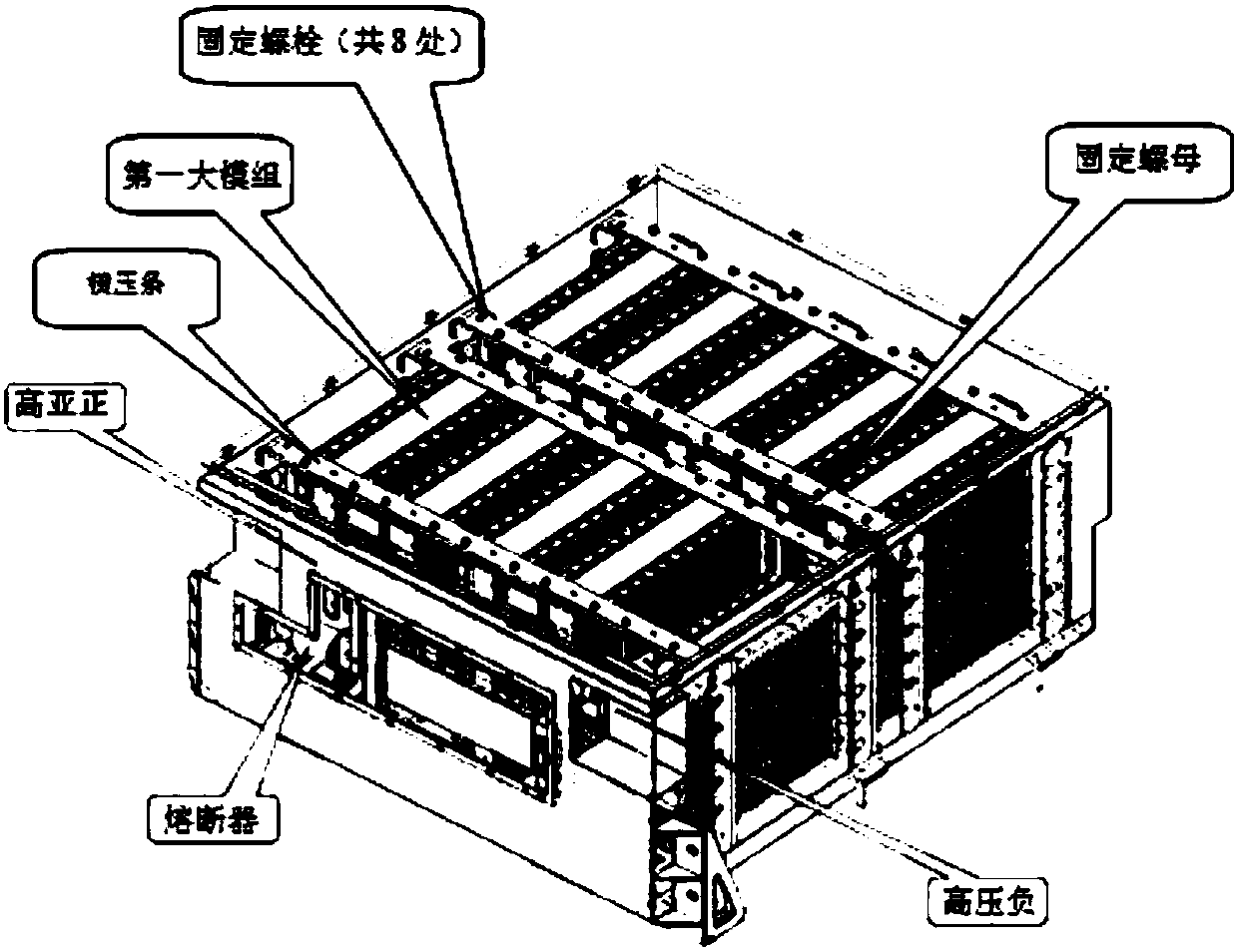

[0063] Let's take a pouch battery system as an example

[0064] The battery system disassembly process is as follows:

[0065] Station 1: Hoisting on-line

[0066] Equipment: Three-axis hoisting system

[0067] Steps: 1. The cart enters the waiting station

[0068] 2. The controller moves the hoisting manipulator above the trolley

[0069] 3. The controller lowers the boom, and the fixing device connects the boom to the bottom of the box

[0070] 4. The controller lifts the cabinet and slowly moves it onto the double-speed line body

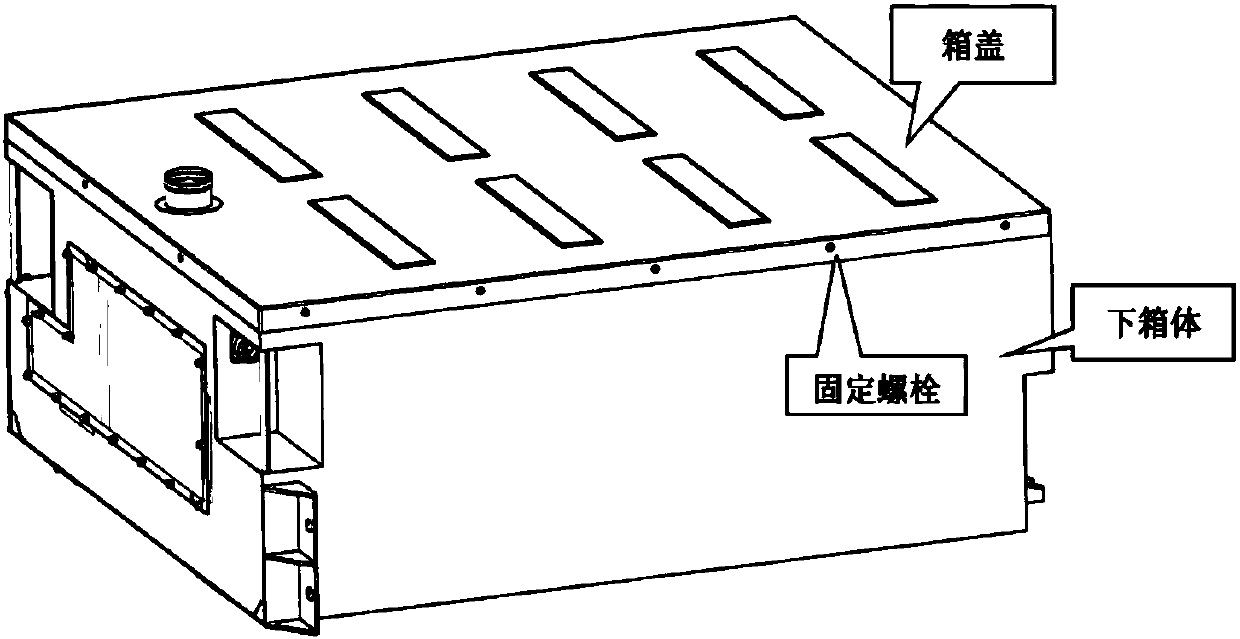

[0071] Station 2: Remove the fixing bolts between the upper and lower boxes

[0072] Equipment: electric screwdriver, steering mechanism

[0073] Steps: 1. Remove the 5 bolts of the front box with an electric screwdriver;

[0074] 2. Use the rotating mechanism to turn the box 90°, 180°, 270°, 360° in sequence, and remove the 2, 5, and 2 bolts in the forward direction. After the removal, the battery system returns to the initial state

[0...

Embodiment 2

[0145] This embodiment takes a cylindrical battery system as an example

[0146]The battery system disassembly process is as follows:

[0147] Station 1: Hoisting on-line

[0148] Equipment: Three-axis hoisting system

[0149] Steps: 1. Push the trolley to the waiting station

[0150] 2. Operate the controller to move the hoisting manipulator above the trolley

[0151] 3. Operate the controller to lower the boom, and the fixing device connects the boom to the bottom of the box

[0152] 4. Operate the controller to lift the cabinet, move it slowly and put it on the double-speed line body

[0153] Station 2: Remove the fixing bolts between the upper and lower boxes

[0154] Steps: 1. Manually remove the 6 bolts above the front box

[0155] 2. Use the rotating mechanism to turn the box 90°, 180°, 270°, 360° in sequence, and remove the 8, 6, and 8 bolts facing the human direction. After the removal, the battery pack returns to the original state

[0156] 3. The battery pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com