Method and system for noise mitigation in multi-beam scanning electron microscopy system

An electron microscope, electron microscope technology, applied in microscopes, circuits, discharge tubes, etc., can solve problems such as shortening inspection time, separation of noise and image information, and lack of sufficient feature information to extract noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

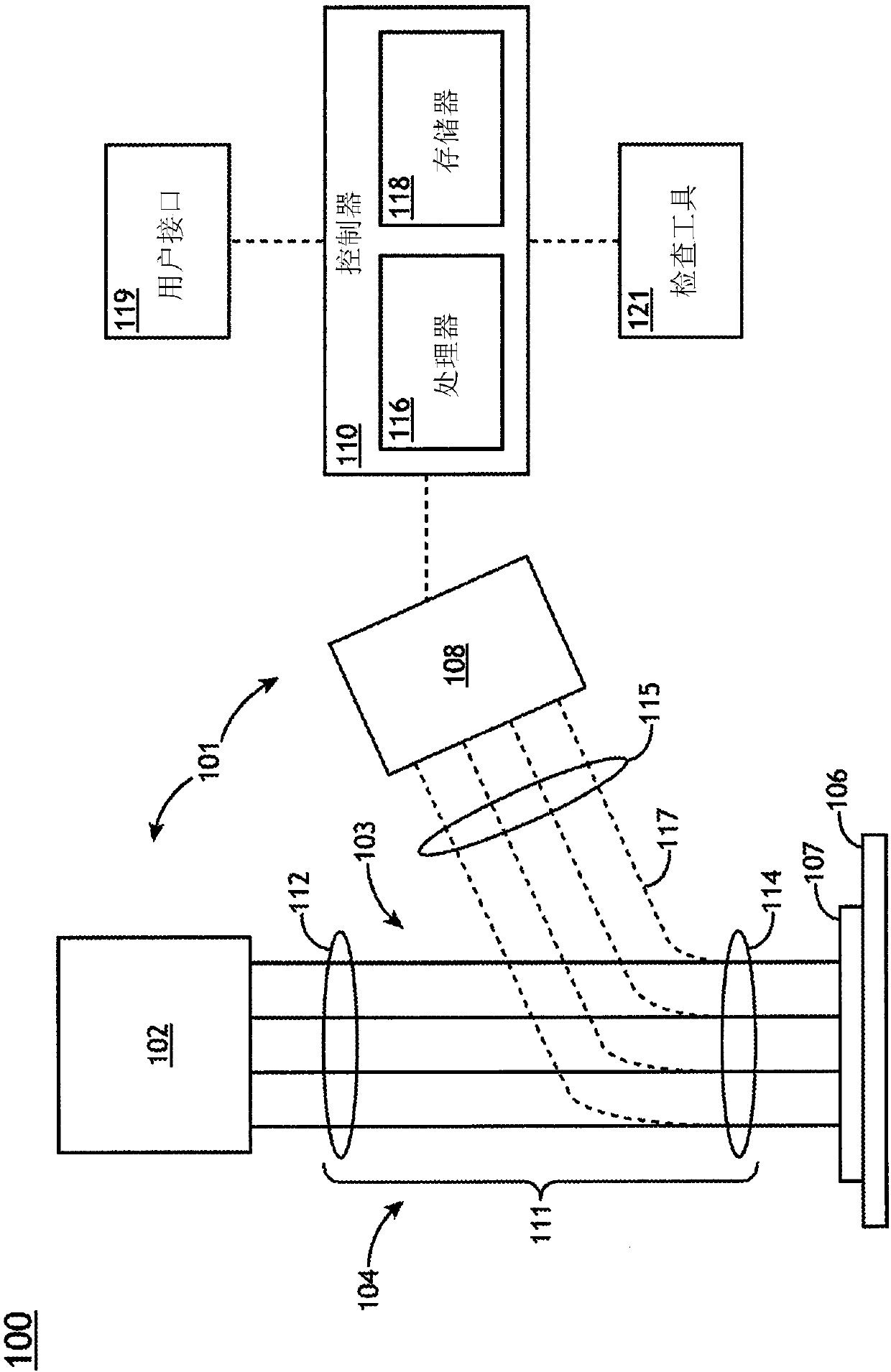

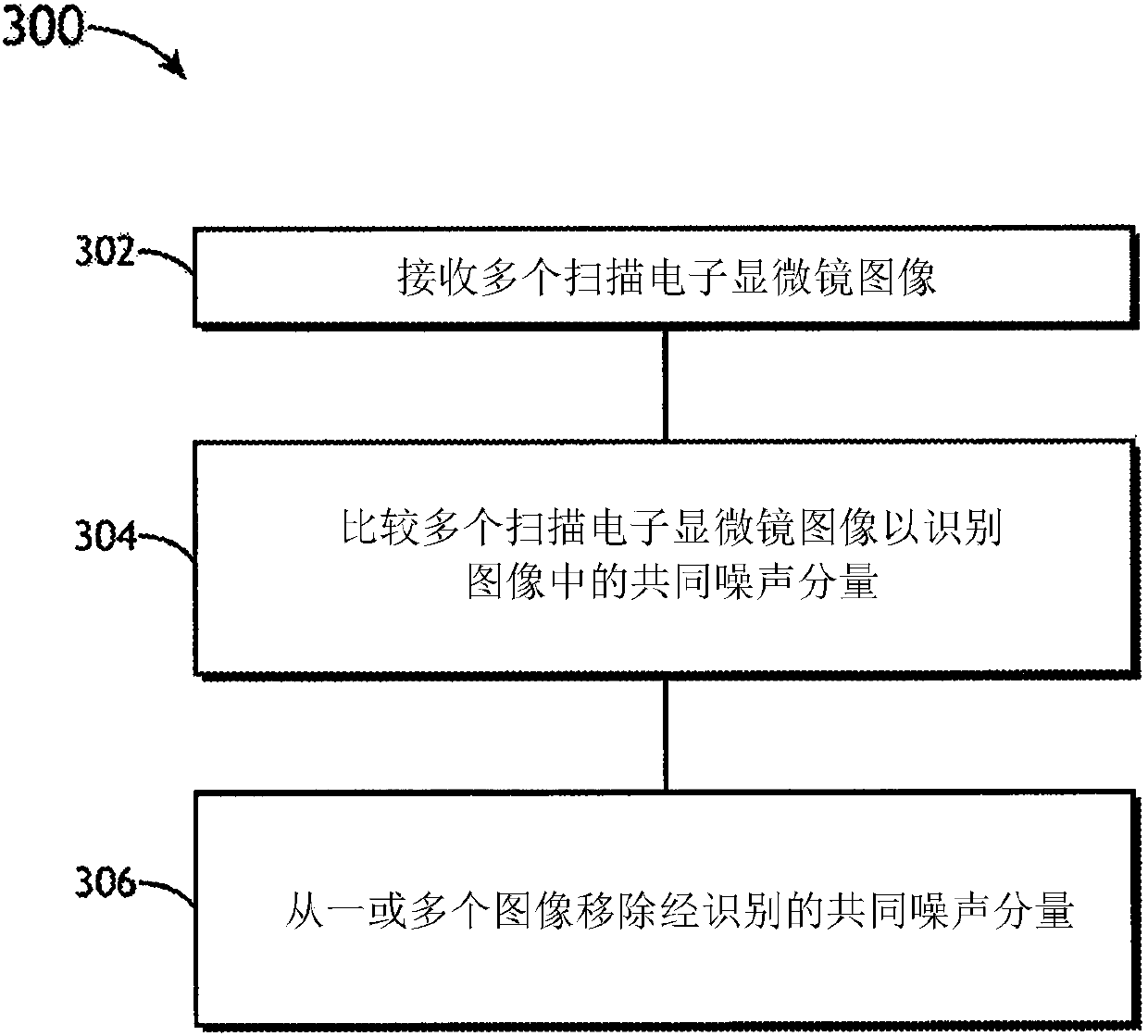

[0018] Reference will now be made in detail to the disclosed subject matter which is illustrated in the accompanying drawings. generally refer to figure 1 A to 3C, systems and methods for reducing noise in a multi-beam scanning electron microscope (SEM) imaging system are described according to the present invention.

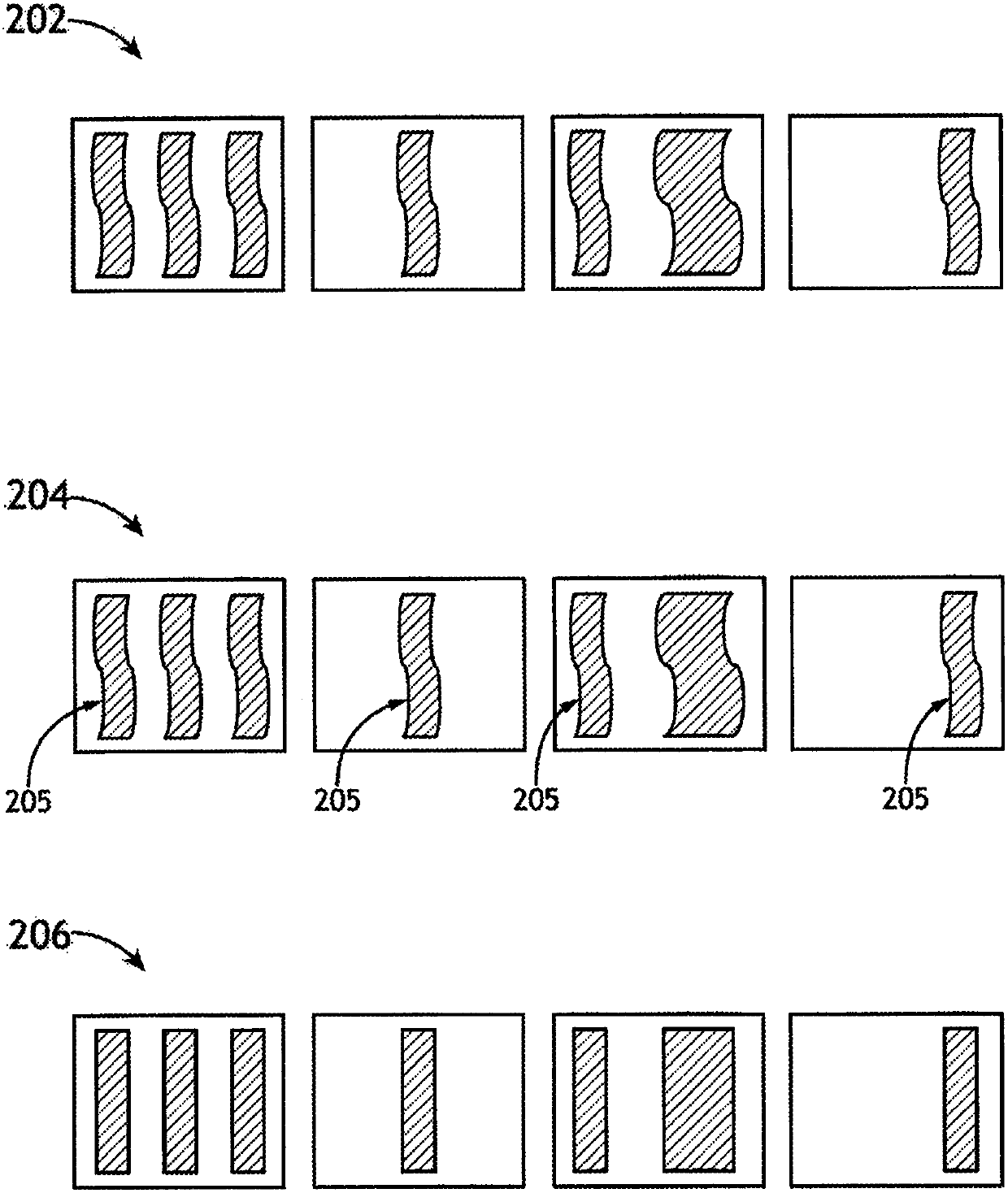

[0019] Embodiments of the invention relate to reducing or eliminating common mode noise in multi-beam SEM systems. It should be noted that this noise can come from a variety of sources including, but not limited to, vibrational noise, acoustic noise, electrical noise (eg, 60Hz noise), errors / faults in the high voltage power supply, and intensity noise occurring in the electron source or electron gun. Noise components may be positional noise (eg, at x-position, y-position, and / or z-position (focus)) or intensity (ie, brightness). Additional embodiments of the invention relate to correcting for the presence of noise components in multiple images (eg via image p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com