Catalyst for preparing beta-ionone, preparation method of catalyst and method for preparing beta-ionone by catalyst

An ionone and catalyst technology, which is applied in the field of catalysts for preparing beta-ionone, can solve the problems of high equipment requirements, harsh operating conditions, and difficult separation, and achieve the effects of reducing the difficulty of separation, reducing the difficulty of production, and reducing conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

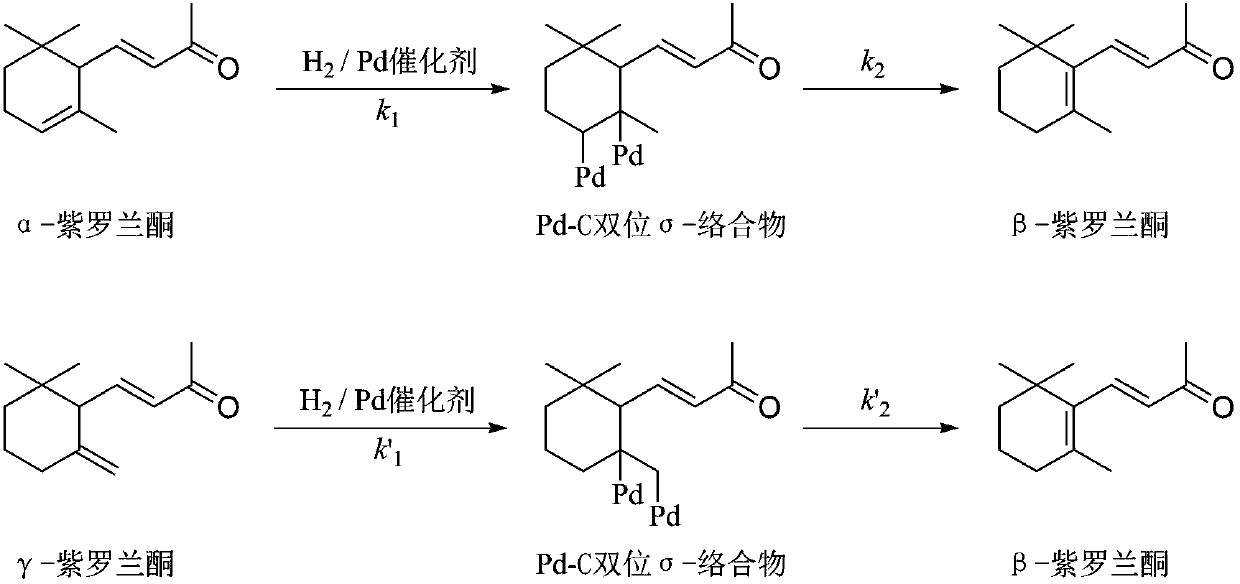

Method used

Image

Examples

Embodiment 1

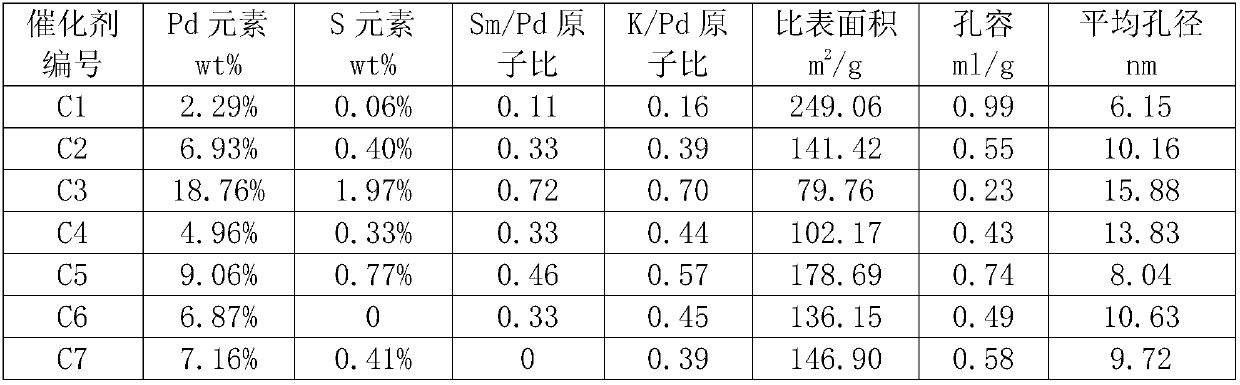

[0038] Weigh PdCl 2 Solid 8 g and SmCl 3 1.3 grams of solid, dissolved in 200 grams of 0.5wt% hydrochloric acid aqueous solution, added 200 grams of carrier γ-Al 2 o 3 Immerse for 5 hours, then dry at 90°C for 24 hours, then bake at 400°C for 8 hours, then reduce with pure hydrogen at 100°C for 12 hours, and then impregnate in 210 grams of K with a concentration of 0.3wt%. 2 SO 4 In the solution for 5 hours, then dried at 90°C for 24 hours, then calcined at 400°C for 6 hours, and then reduced with pure hydrogen at 100°C for 12 hours to obtain Pd-Sm-S-K / γ-Al 2 o 3 Catalyst C1. The composition of the catalyst and the physical property data obtained by nitrogen physical adsorption are shown in Table 1.

Embodiment 2

[0040] Weigh PdCl 2 Solid 26.5 g and SmCl 3 12.5 grams of solid, dissolved in 250 grams of 3.5wt% hydrochloric acid aqueous solution, added 200 grams of carrier γ-Al 2 o 3 Immerse for 10 hours, then dry at 105°C for 15 hours, then bake at 700°C for 5 hours, then reduce with pure hydrogen at 350°C for 9 hours, and then soak in 170 grams of K with a concentration of 3wt%. 2 SO 4 In the solution for 10 hours, then dried at 105°C for 15 hours, then calcined at 700°C for 4.5 hours, and then reduced with pure hydrogen at 350°C for 9 hours to obtain Pd-Sm-S-K / γ-Al 2 o 3 Catalyst C2. The composition of the catalyst and the physical property data obtained by nitrogen physical adsorption are shown in Table 1.

Embodiment 3

[0042] Weigh PdCl 2 Solid 61 g and SmCl 3 63.5 grams of solid, dissolved in 250 grams of 7wt% hydrochloric acid aqueous solution, added 100 grams of carrier γ-Al 2 o 3 Immerse for 16 hours, then dry at 120°C for 6 hours, then bake at 1000°C for 2 hours, then reduce with pure hydrogen at 600°C for 6 hours, and then impregnate in 210 grams of 10wt% K 2 SO 4 In solution for 16 hours, then dried at 120°C for 6 hours, then calcined at 1000°C for 3 hours, and then reduced with pure hydrogen at 600°C for 6 hours to obtain Pd-Sm-S-K / γ-Al 2 o 3 Catalyst C3. The composition of the catalyst and the physical property data obtained by nitrogen physical adsorption are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com