Micro-fluidic chip template, preparation method thereof and application of template

A technology of microfluidic chips and templates, which is applied to chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problems of poor reproducibility, difficulty in ensuring experimental results, and increased experimental costs, so as to achieve simple production, The effect of simple preparation method and readily available materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of preparation method of microfluidic chip template

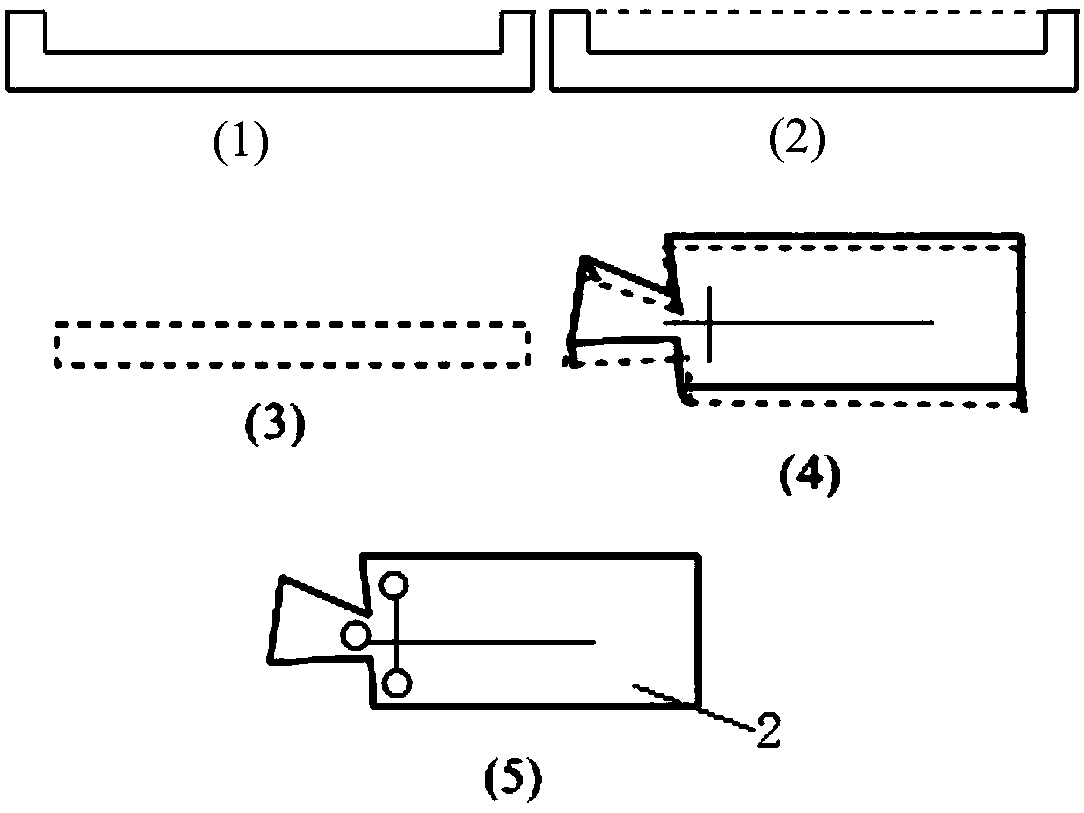

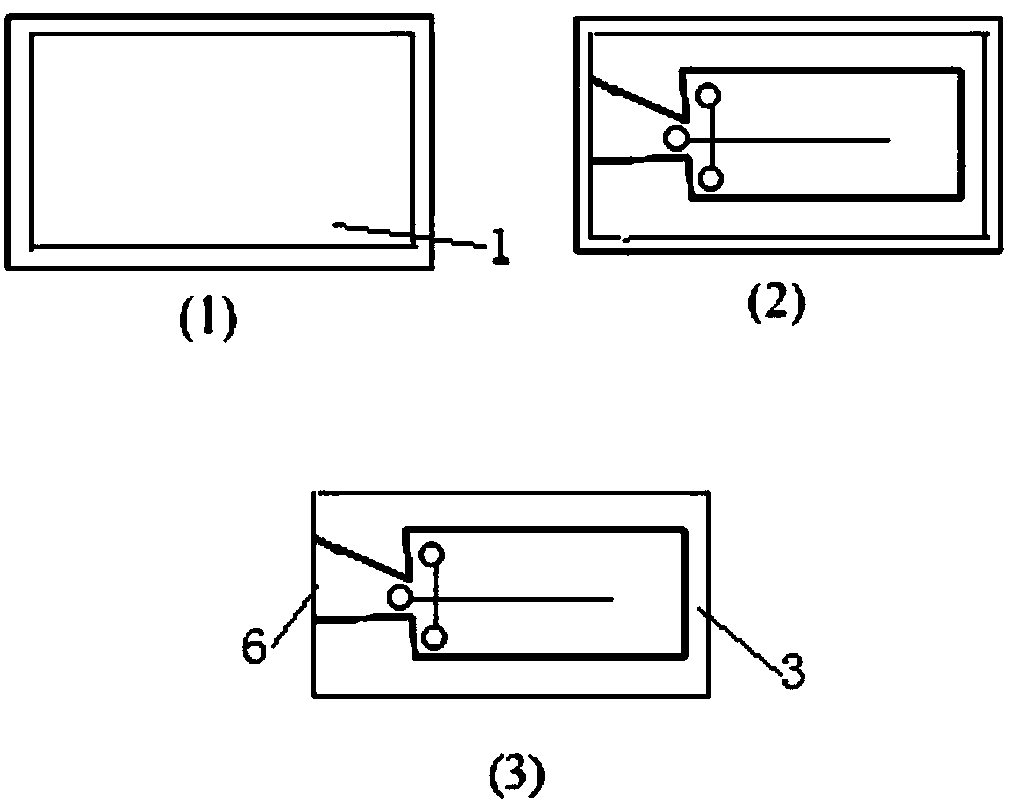

[0029] Step 1: If figure 1 As shown, the PDMS monomer and the curing agent are mixed at a mass ratio of 10:1 to obtain a PDMS prepolymer, which is injected onto the GaAs male mold with a convex cross-shaped microchannel, vacuumed and left for 25-35 minutes to remove air bubbles. Heating for 2 hours to solidify the PDMS prepolymer, and then peel off from the GaAs positive mold to obtain a solid PDMS prepolymer with concave cross-shaped micro-channels, cut, and punch a hole at each of the three ports adjacent to the concave cross-shaped micro-channels , respectively serving as the sample pool, the buffer pool, and the waste pool to prepare the microfluidic chip 2;

[0030] Step 2: If figure 2 As shown, the microfluidic chip 2 prepared in step 1 is placed in the open silica gel mold 1, so that the surface of the microfluidic chip 2 with the cross micropipe faces upward, and the protruding end of the microfluid...

Embodiment 2

[0033] Application of a microfluidic chip template

[0034] Step 1: Prepare a microfluidic chip template 3 by using the preparation method of a microfluidic chip template in Example 1.

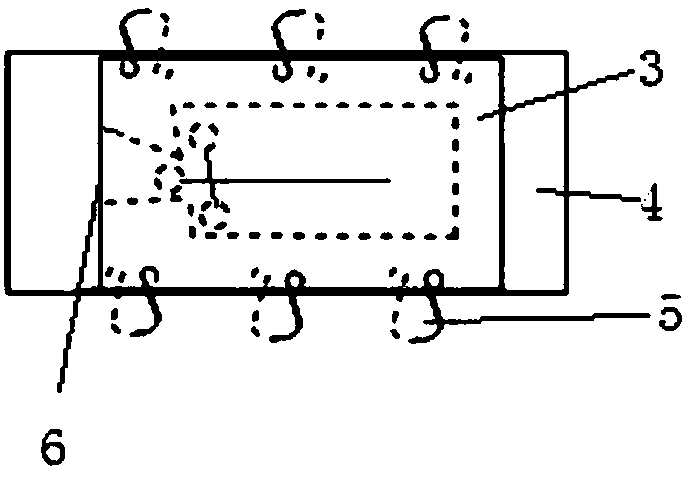

[0035] Step 2: If image 3 As shown, it includes the following steps: attaching the microfluidic chip template 3 to the plexiglass plate 4 to form an inner cavity, clamping and fixing the microfluidic chip template 3 and the plexiglass plate 4 with a clamp, and removing the PDMS prepolymer from the microfluidic chip The opening 6 on the fluidic chip template 3 is poured into the inner cavity, and the PDMS prepolymer is peeled off after curing to obtain a new microfluidic chip with exactly the same hole position and pipe length as the original prepared microfluidic chip 2. control chip 2.

[0036] When using the microfluidic chip 2 prepared by the microfluidic chip template 3 of the present invention, it is necessary to place a PDMS substrate under the prepared new microfluidic chip 2, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com