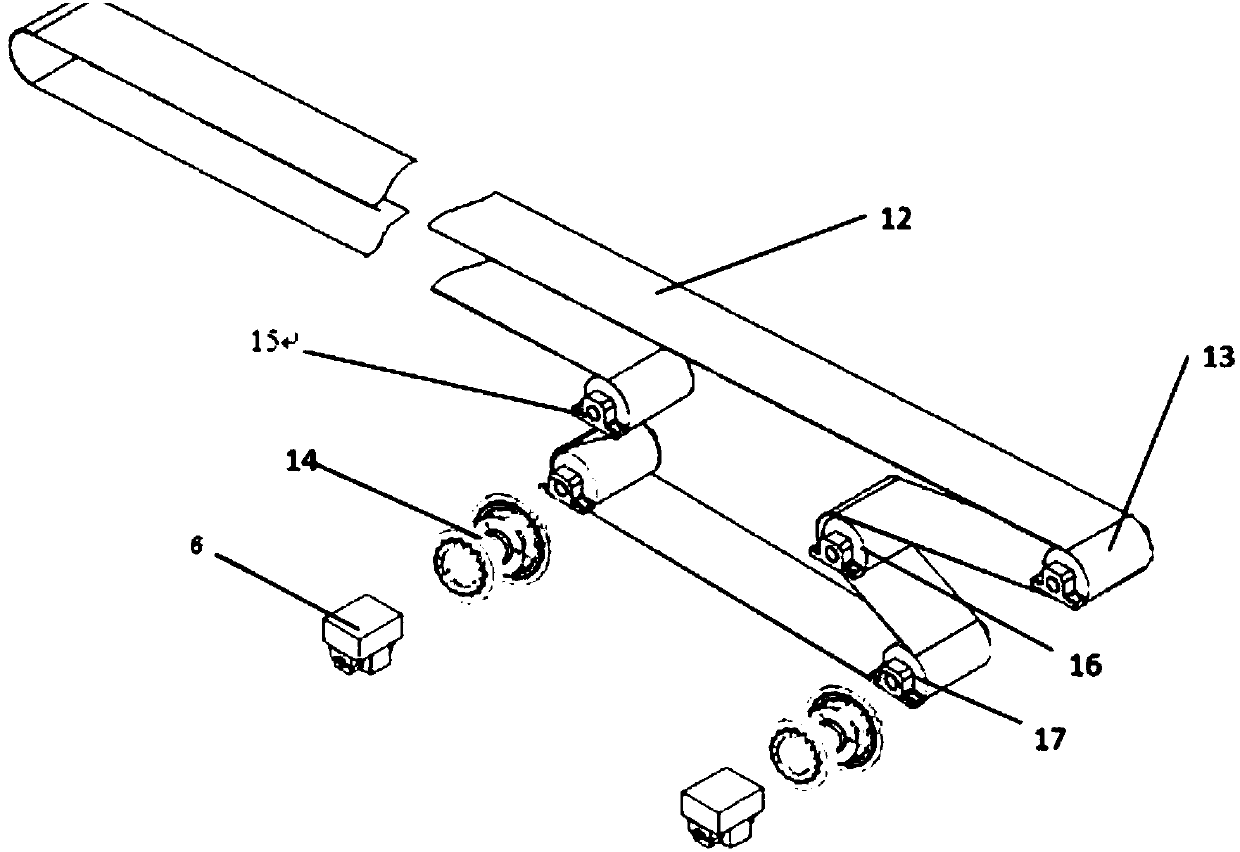

Bulk conveyor adopting variable-thickness planetary gearbox

A planetary gearbox and planetary gear technology, which is applied in the direction of conveyors, conveyor objects, belts/chains/gears, etc., can solve problems such as extremely high processing technology requirements, impact resistance crossover, and limited application range, and achieve reliable Process, stable control speed, safe and reliable effect of transmission process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

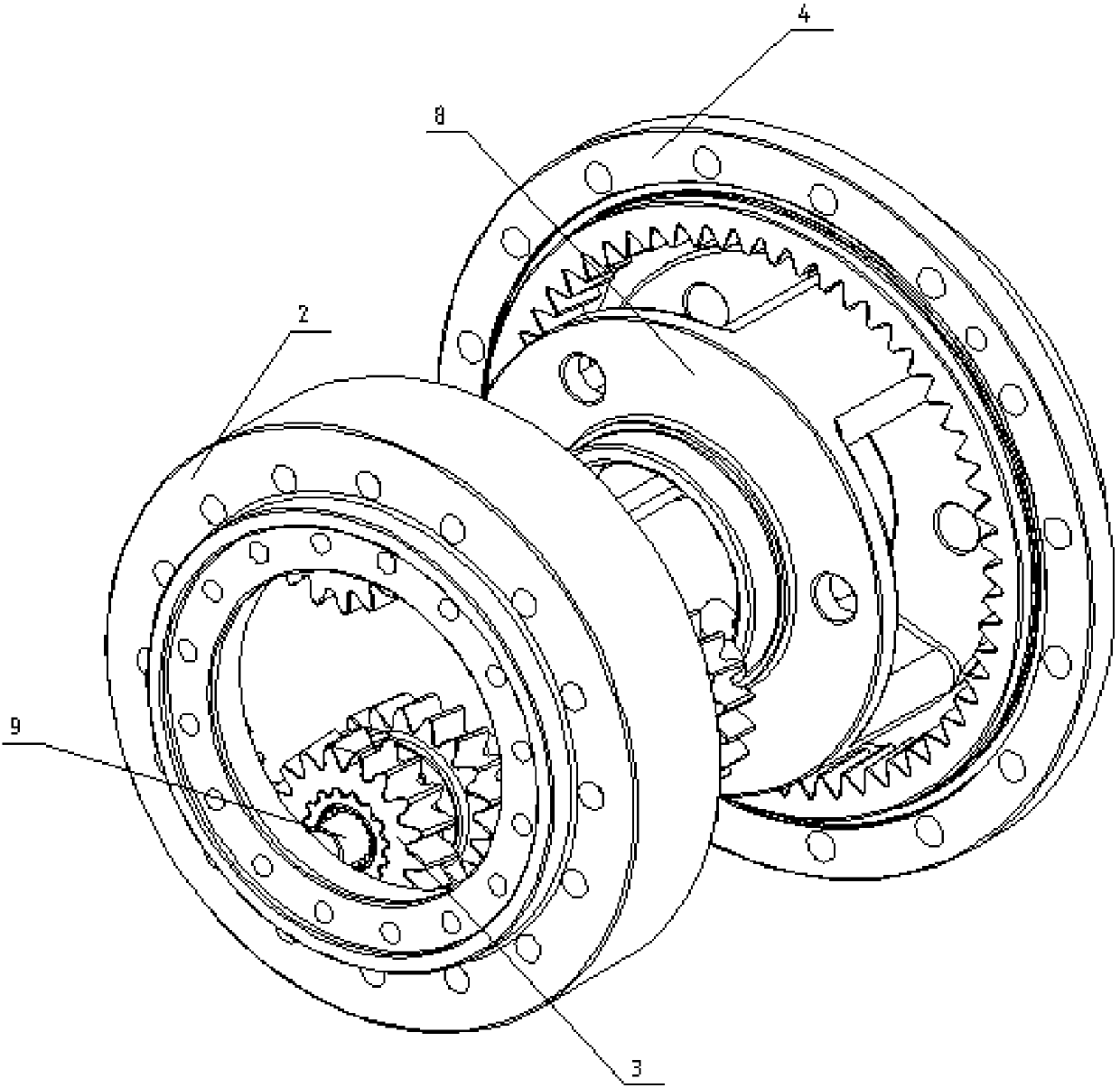

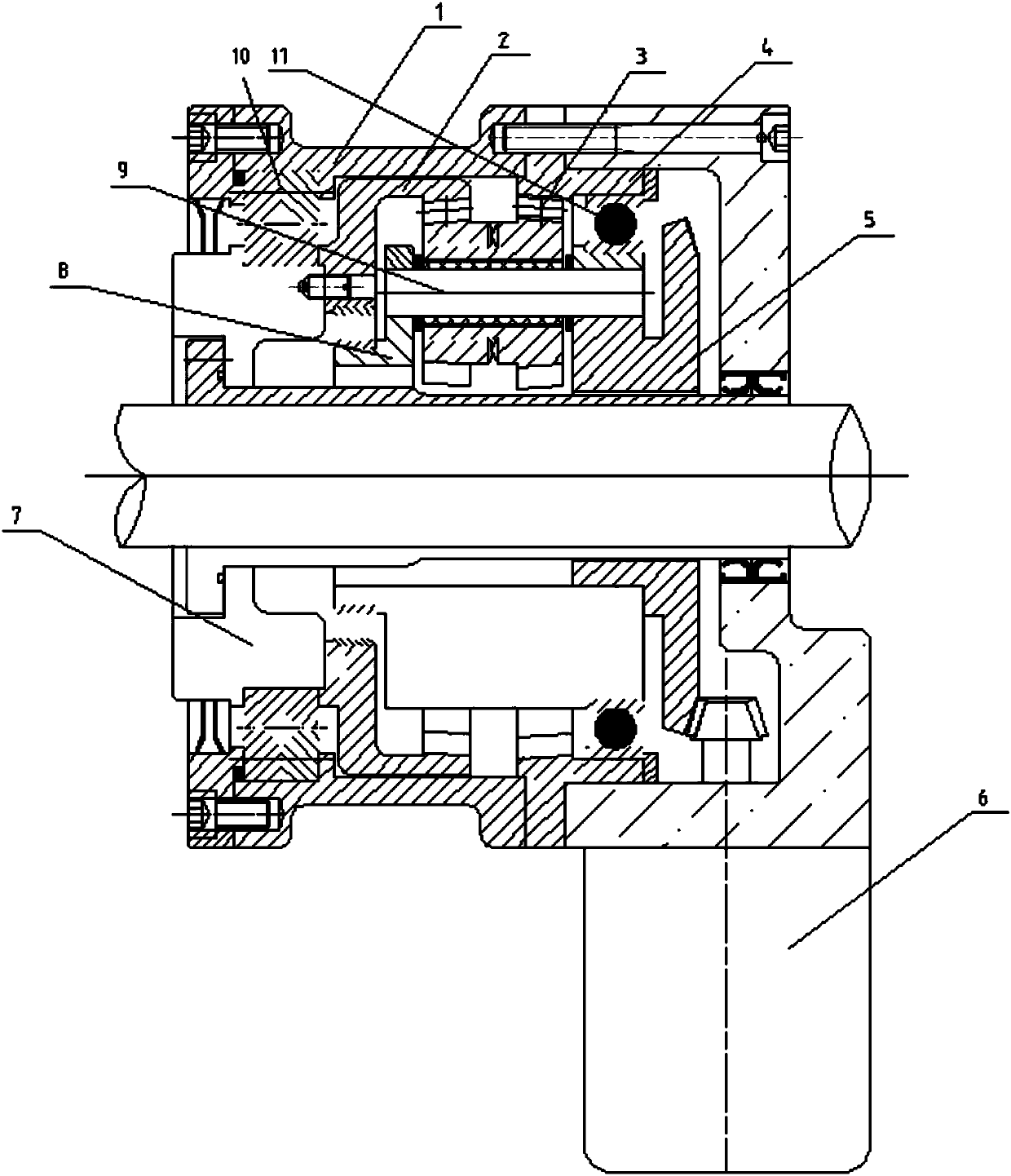

[0027] The driving motor 6 drives the first-stage transmission chain 5, and a gear in the transmission chain drives the planetary carrier 8 to rotate, and the planetary carrier 8 drives the planetary pin 9 to rotate along the center, and simultaneously drives the double-thickened planetary gear 3 to rotate and revolve; the thickened ring gear 2 is fixed on the box shell assembly 1, and the rotation speed is 0 rpm.

[0028] Driven by the planetary gear, the first thickened ring gear and the output shaft are connected to the output shaft 9 through interference or fixed pins or bolts, so that there is an output speed, and the double thickened planetary gear 2 and The first thickened ring gear, the left and right sides of the double thickened planetary gear 3 ensure that the output gap and return stroke difference are extremely small, the first stage transmission speed ratio is i1, and the teeth numbers of the thickened ring gear are z2, z4 respectively; double thickened The numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com