Transparent powder coating

A powder coating and transparent technology, applied in anti-corrosion coatings, polyester coatings, coatings, etc., can solve the problems of large decay, migration, and single surface, and achieve improved leveling, convenient storage and transportation, and excellent weather resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 A kind of preparation of transparent powder coating

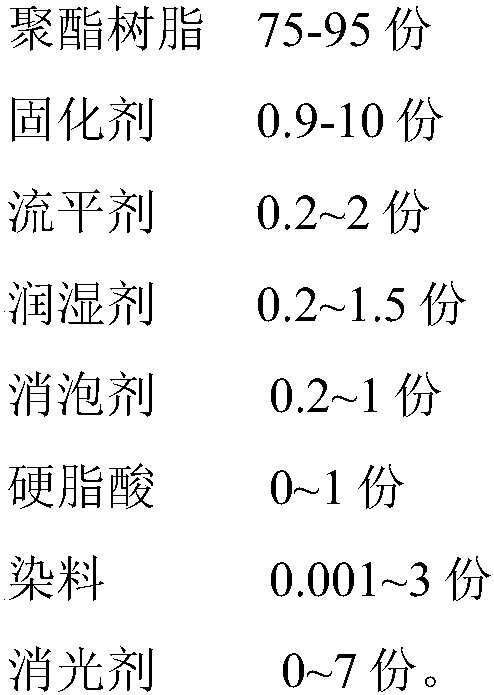

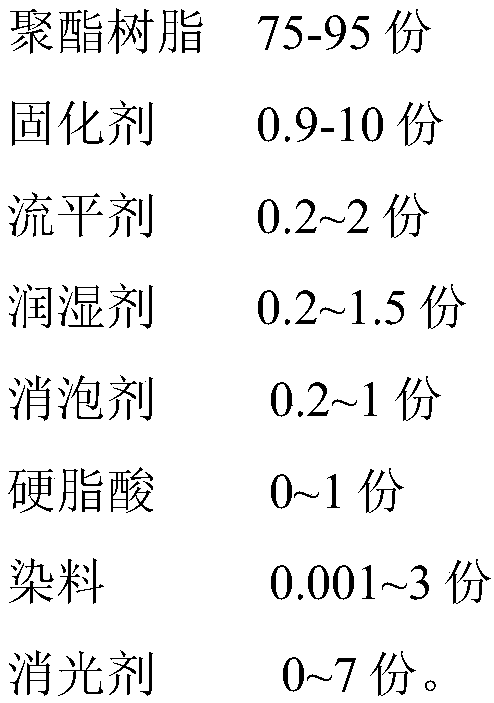

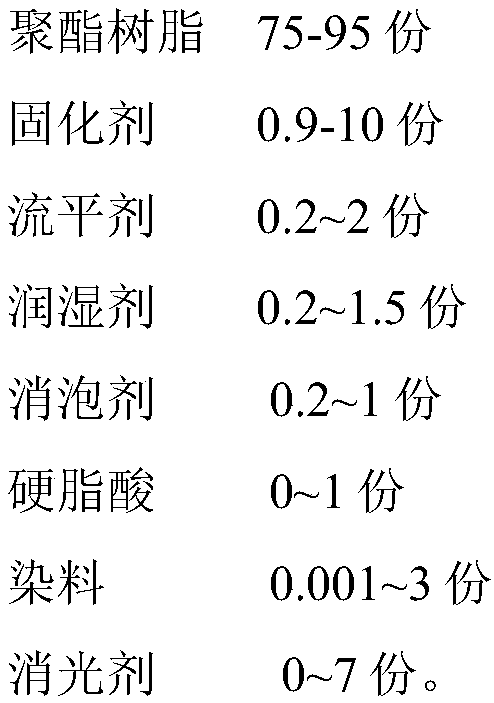

[0025] A kind of transparent powder paint, described powder paint comprises following weight component raw material:

[0026]

[0027] The above-mentioned raw materials are mixed in proportion, kneaded and extruded in an extruder, and then crushed by tableting, pulverized and sieved by a micro pulverizer to obtain the transparent powder coating.

Embodiment 2

[0028] Embodiment 2: The application of a kind of transparent powder coating, the above-mentioned powder coating is used for various metal workpieces.

[0029] (1) Pretreatment: In the actual application process, the pretreatment process is different according to the substrate material and the specific application site, and the above pretreatment process is adjusted according to different actual application processes.

[0030] (2) Spraying

[0031] The coating is sprayed onto the surface of the metal workpiece by corona electrostatic spraying. The curing parameters during the spraying process are 200° C. for 10 minutes. The appearance of the coating is flat and high-gloss, and the high-gloss is more than 80% of the gloss measured by a 60-degree gloss meter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com