Production method for pre-melted slag for small-batch electroslag remelting

A technology of electroslag remelting and production method, applied in the field of electroslag remelting production, can solve problems such as difficulty, and achieve the effects of convenient use, reduced moisture absorption performance, and avoiding slag collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

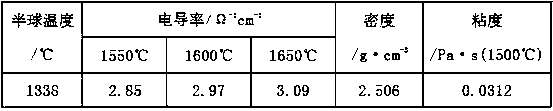

Embodiment 1

[0024] The production method of pre-melted slag for small batch electroslag remelting of the present embodiment comprises the following steps:

[0025] (1) The outer shell is welded with ordinary steel plates, the inner lining is built with refractory materials, and a slag bag with a capacity of 300kg is selected;

[0026] (2) Take pre-melted slag raw materials, fluorite: 45%, lime: 20%, magnesia: 5%, industrial alumina: 25%, quartz sand: 5%, and put them into a slag baking furnace at 820°C for pre-processing Heat baking, after 8 hours of heat preservation, the temperature is lowered to 300°C and kept at a constant temperature for use;

[0027] (3) Use double graphite electrodes in series with the electroslag furnace, adjust the graphite electrode to be located in the center of the slag bag and 20mm away from the bottom of the bag, insert coke or waste carbon block between the two graphite electrodes as an arc ignition agent, and send electricity to start the arc. After the a...

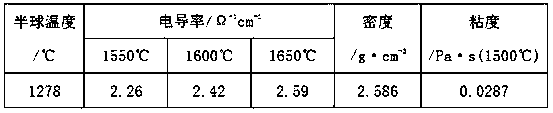

Embodiment 2

[0034] The production method of pre-melted slag for small batch electroslag remelting of the present embodiment comprises the following steps:

[0035] (1) The outer shell is welded with ordinary steel plates, the inner lining is built with refractory materials, and a slag bag with a capacity of 300kg is selected;

[0036] (2) Take pre-melted slag raw materials, fluorite: 55%, lime: 8%, magnesia: 15%, industrial alumina: 15%, quartz sand: 7% as pre-melted slag raw materials, with a total weight of 300kg, put Preheat and bake in a 780°C slag baking oven, keep warm for 10 hours, and then drop to a constant temperature of 350°C for use;

[0037] (3) Use double graphite electrodes in series with the electroslag furnace, adjust the graphite electrode to be located in the center of the slag bag and 20mm away from the bottom of the bag, insert coke or waste carbon block between the two graphite electrodes as an arc ignition agent, and send electricity to start the arc. After the arc...

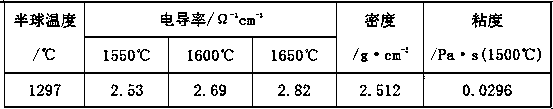

Embodiment 3

[0044] The production method of pre-melted slag for small batch electroslag remelting of the present embodiment comprises the following steps:

[0045] (1) The outer shell is welded with ordinary steel plates, the inner lining is built with refractory materials, and a slag bag with a capacity of 300kg is selected;

[0046] (2) Take pre-melted slag raw materials, fluorite: 70%, lime: 5%, magnesia: 10%, industrial alumina: 10%, quartz sand: 5% as pre-melted slag raw materials, with a total weight of 300kg, put Put it into a 790°C slag oven for preheating and baking, and after keeping it for 9 hours, the temperature will drop to 320°C for use;

[0047] (3) Use double graphite electrodes in series with the electroslag furnace, adjust the graphite electrode to be located in the center of the slag bag and 20mm away from the bottom of the bag, insert coke or waste carbon block between the two graphite electrodes as an arc ignition agent, and send electricity to start the arc. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com