Patents

Literature

39results about How to "Avoid hydrogenation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Purifying crude furan 2,5-dicarboxylic acid by hydrogenation

ActiveUS20130345452A1Lower energy requirementsImprove solubilityOrganic chemistryFuranDicarboxylic acid

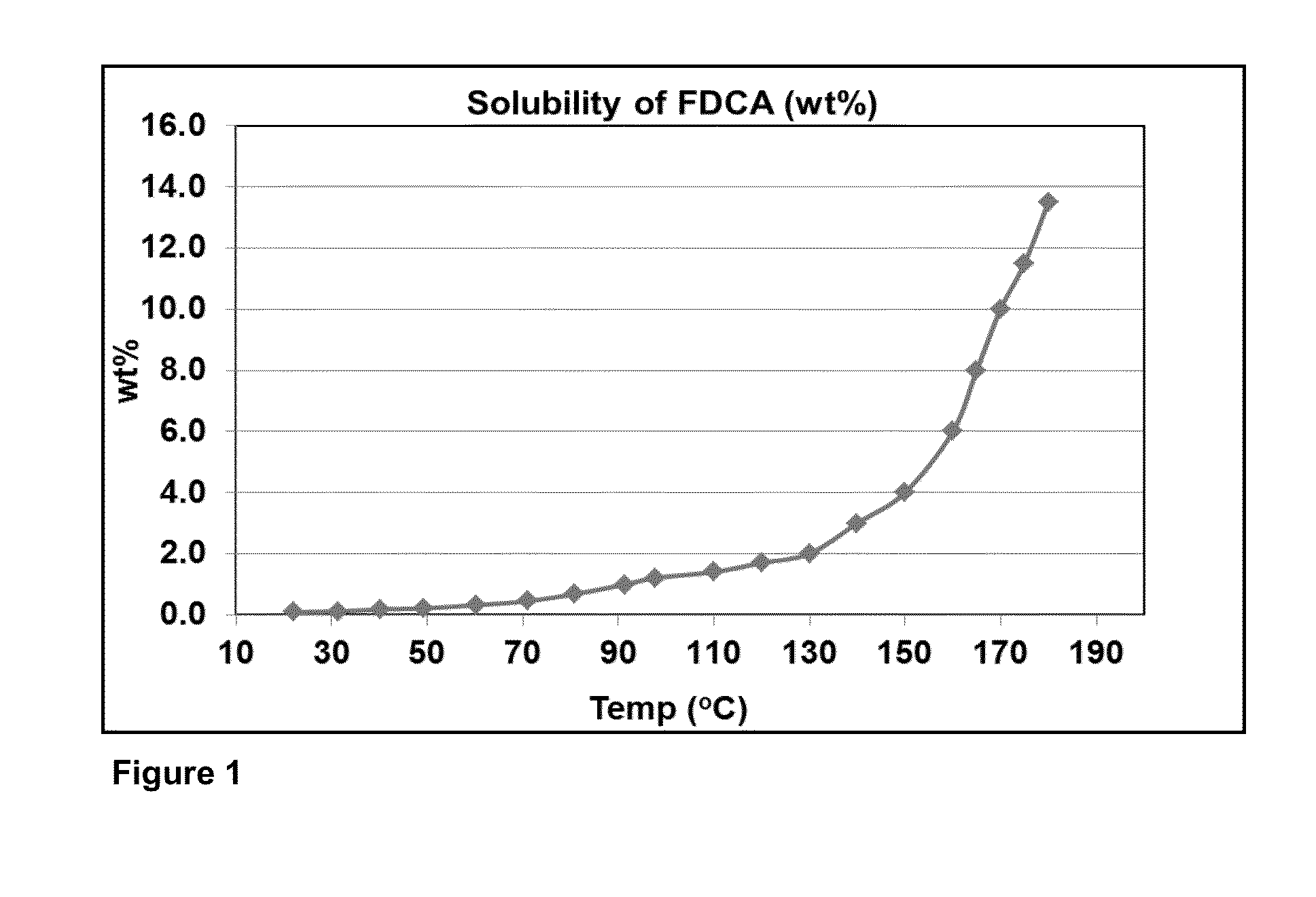

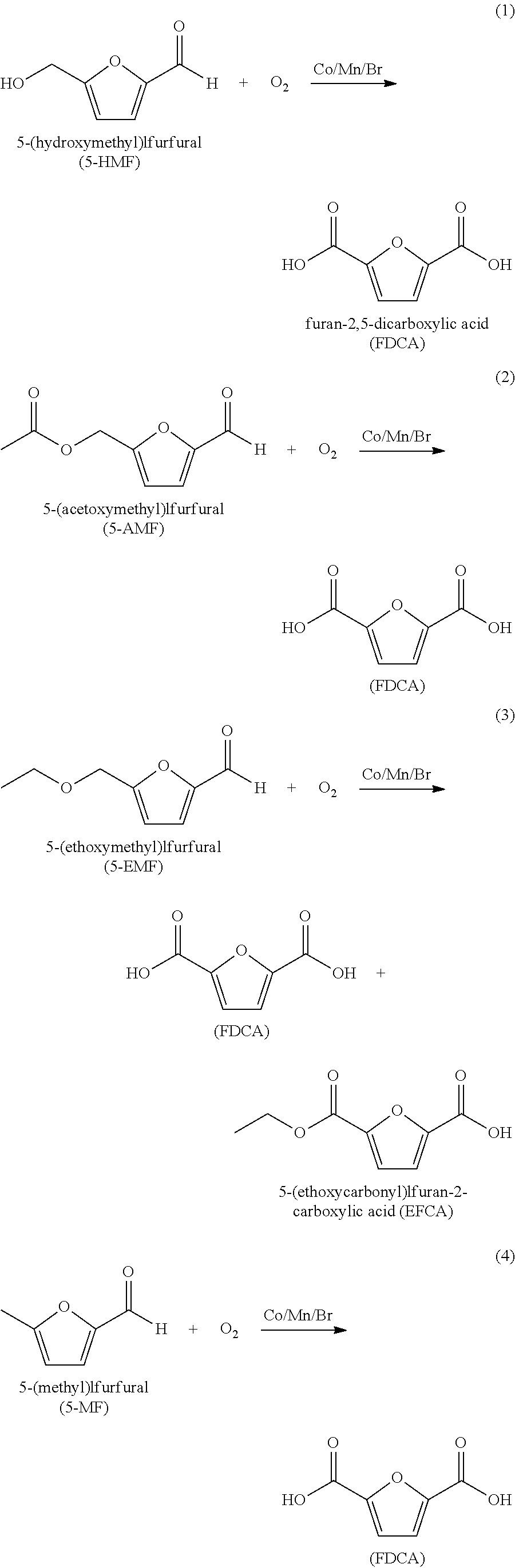

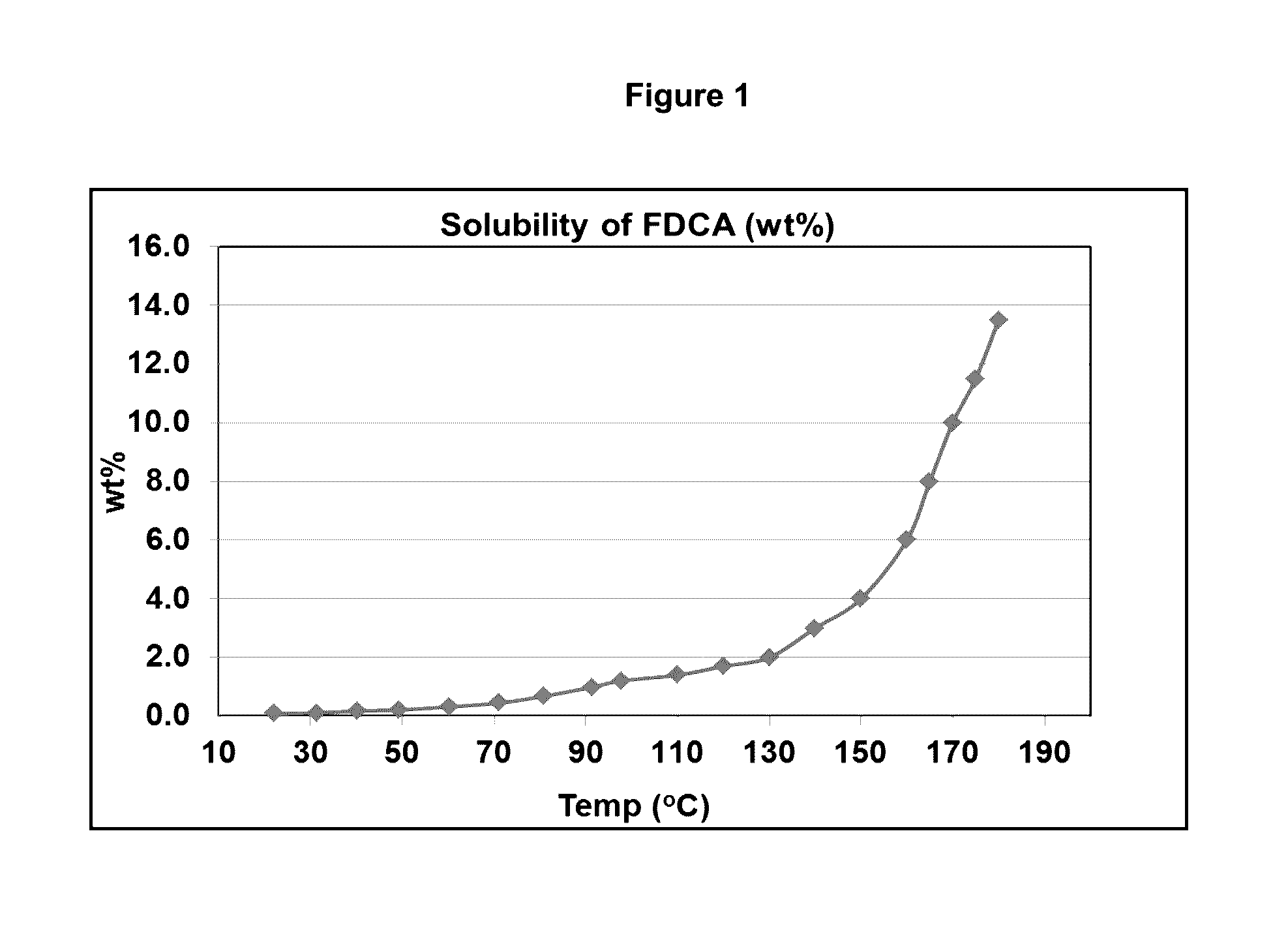

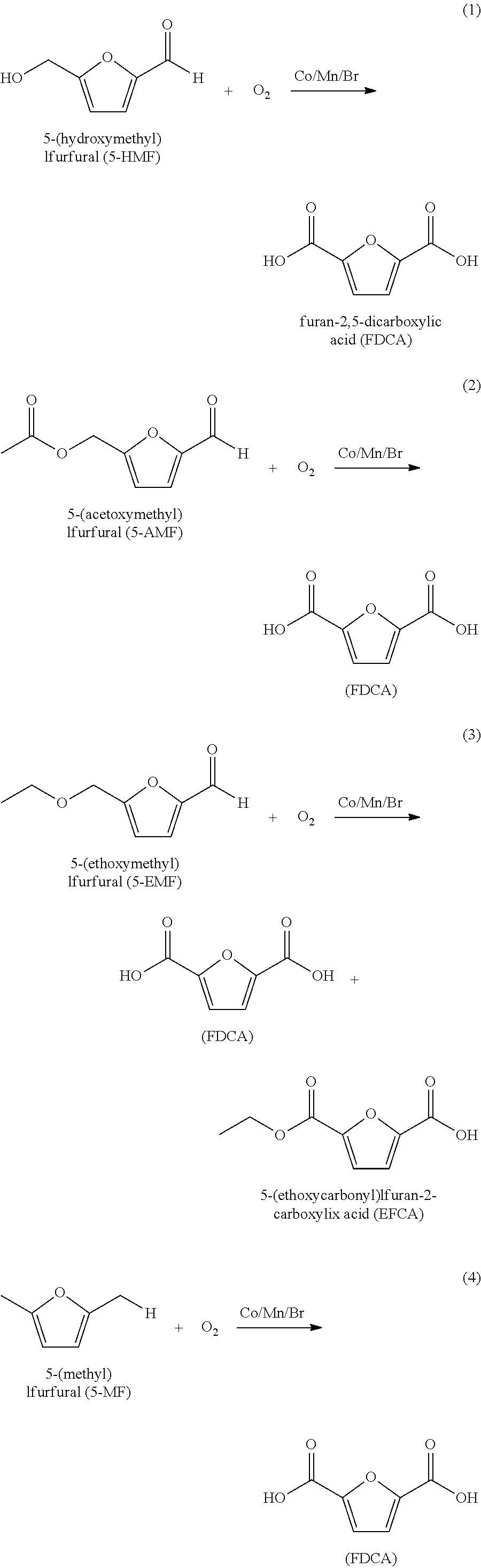

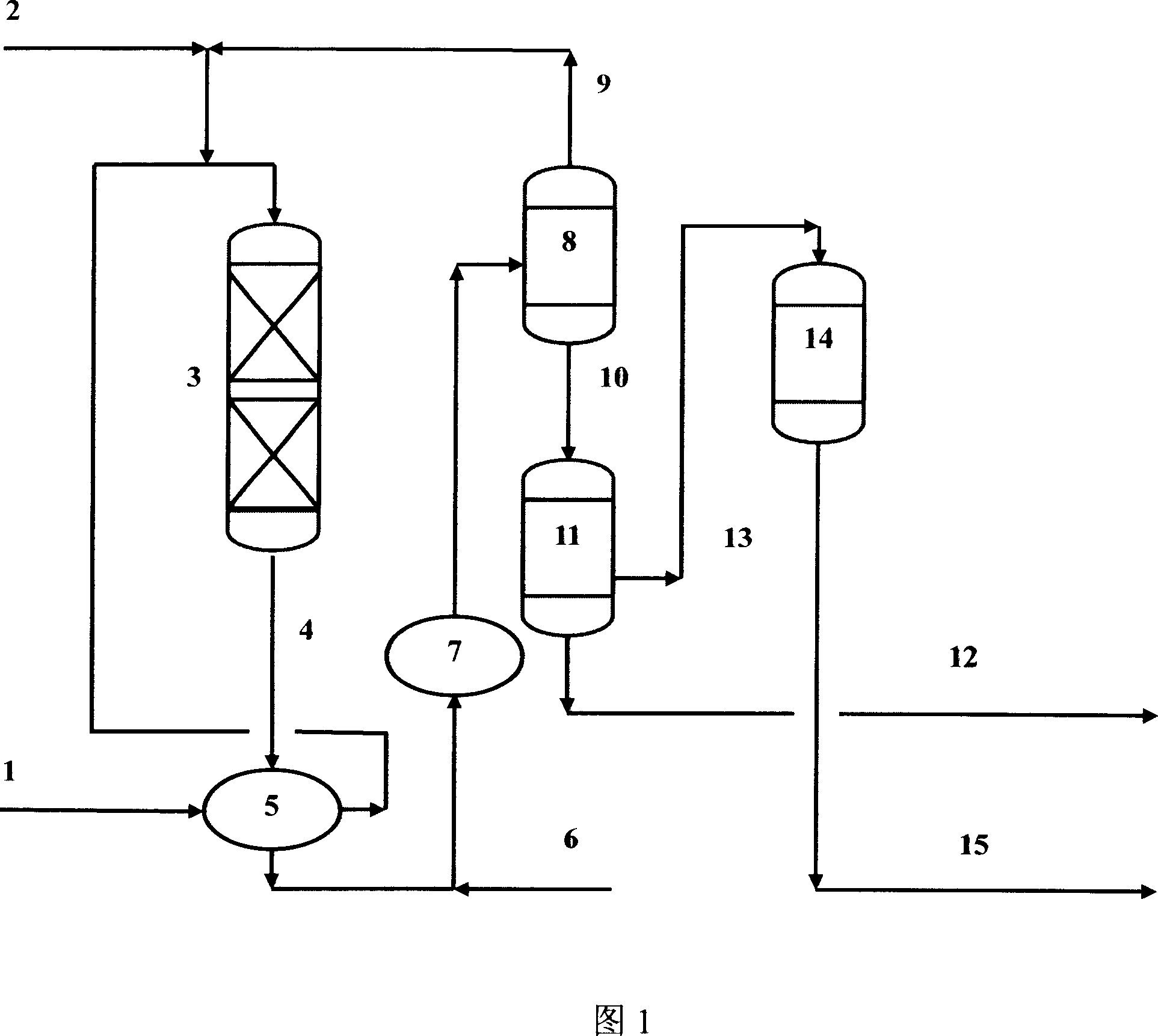

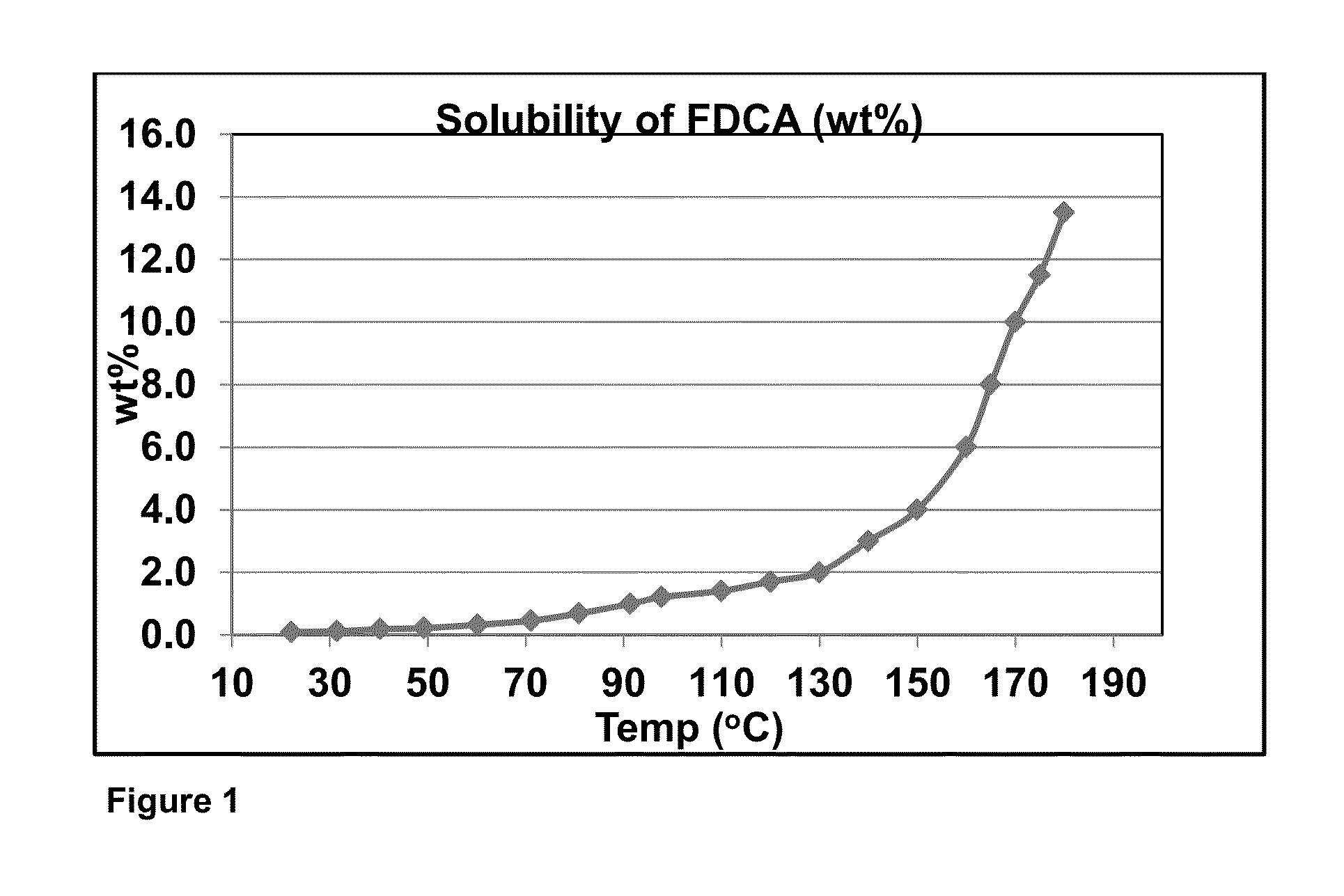

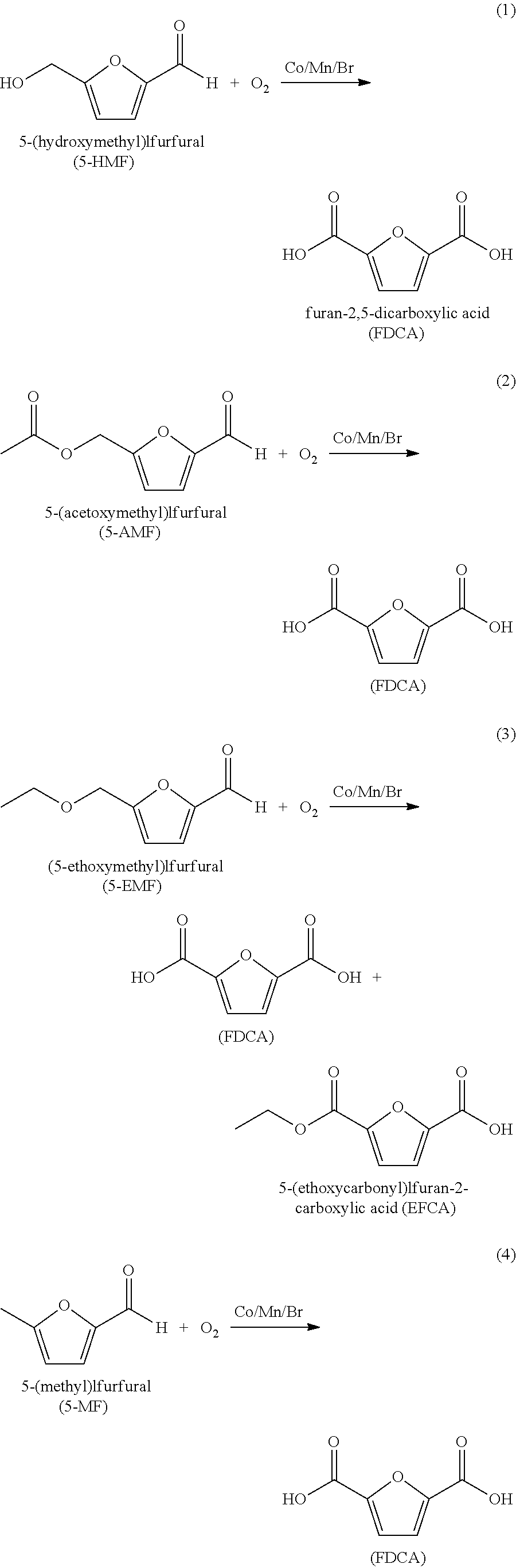

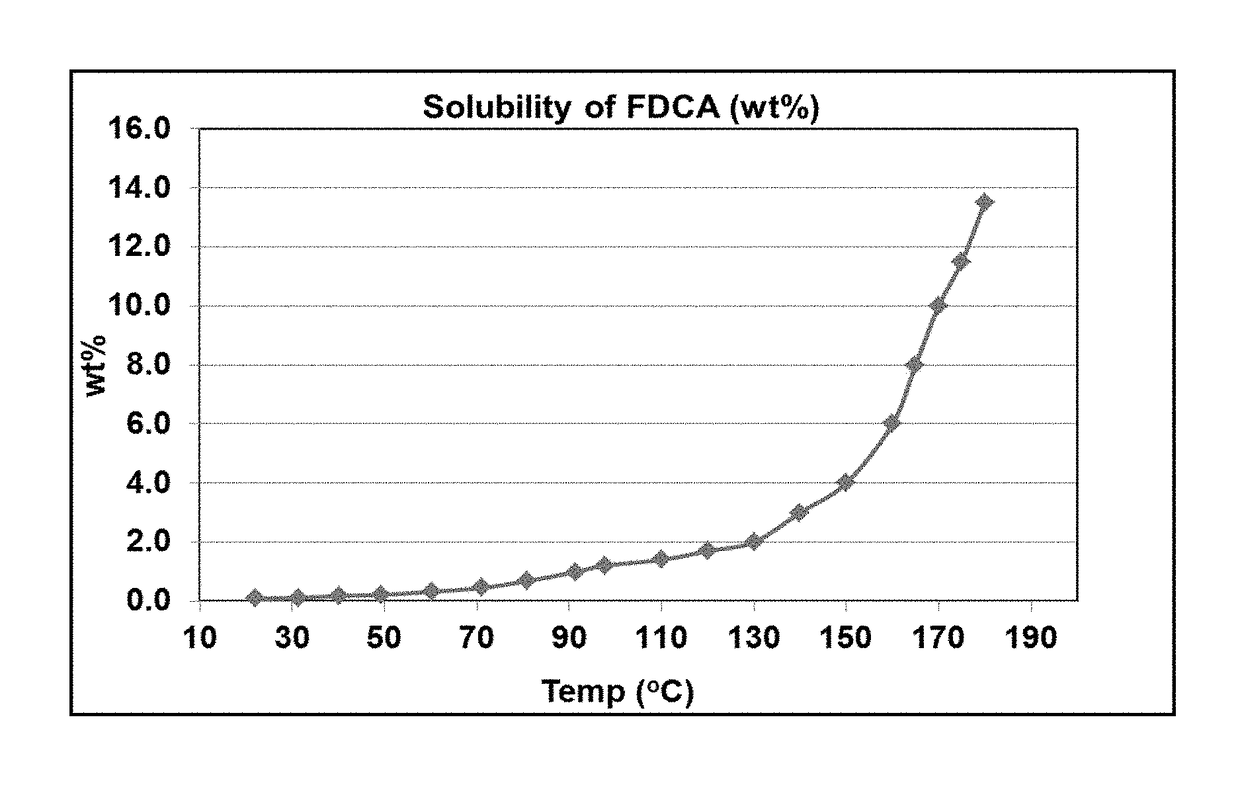

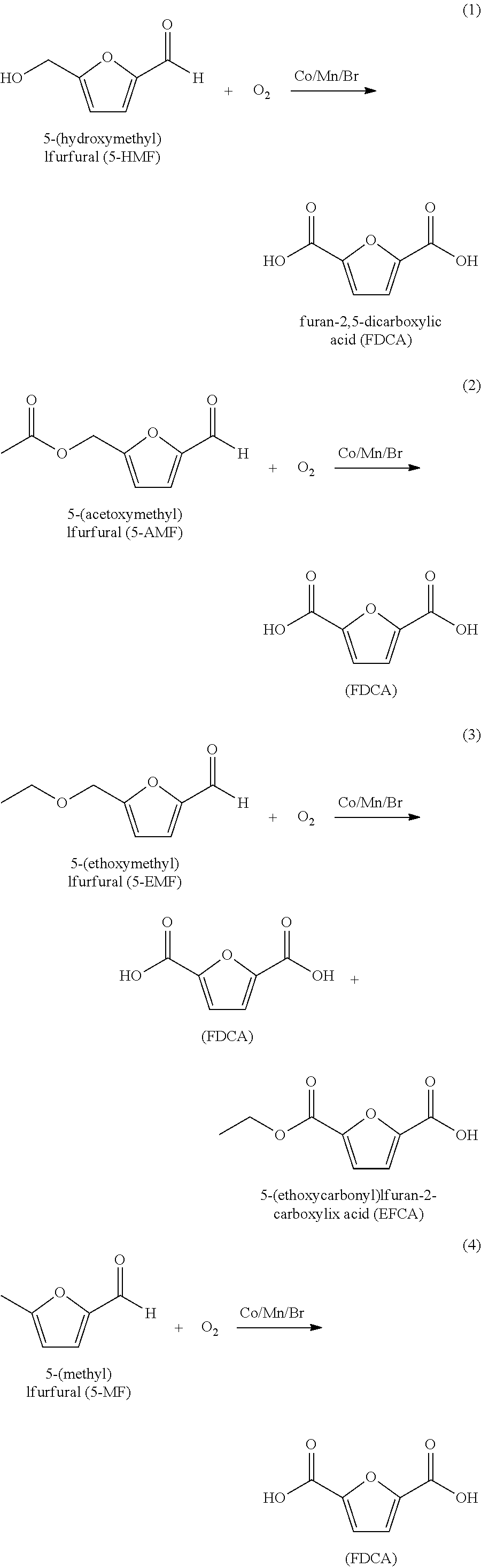

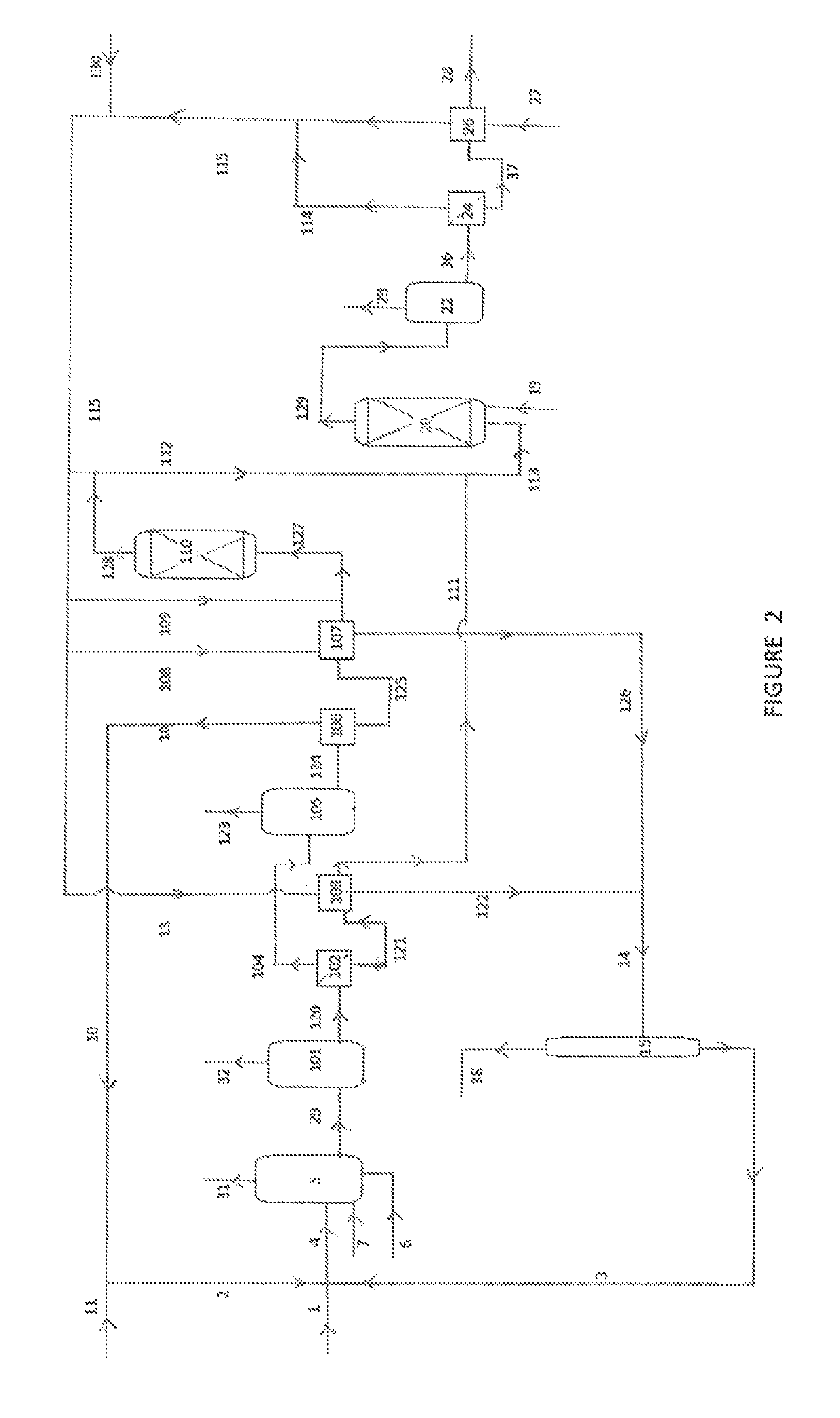

A process for purifying a crude furan 2,5-dicarboxylic acid composition (cFDCA) by hydrogenation of a FDCA composition dissolved in a hydrogenation solvent such as water, and hydrogenating under mild conditions, such as at a temperature within a range of 130° C. to 225° C. by contacting the solvated FDCA composition with hydrogen in the presence of a hydrogenation catalyst under a hydrogen partial pressure within a range of 10 psi to 900 psi. A product FDCA composition is produced having a low amount of tetrahydrofuran dicarboxylic acid, a low b*, and a low amount of 5-formyl furan-2-carboxylic acid (FFCA).

Owner:EASTMAN CHEM CO

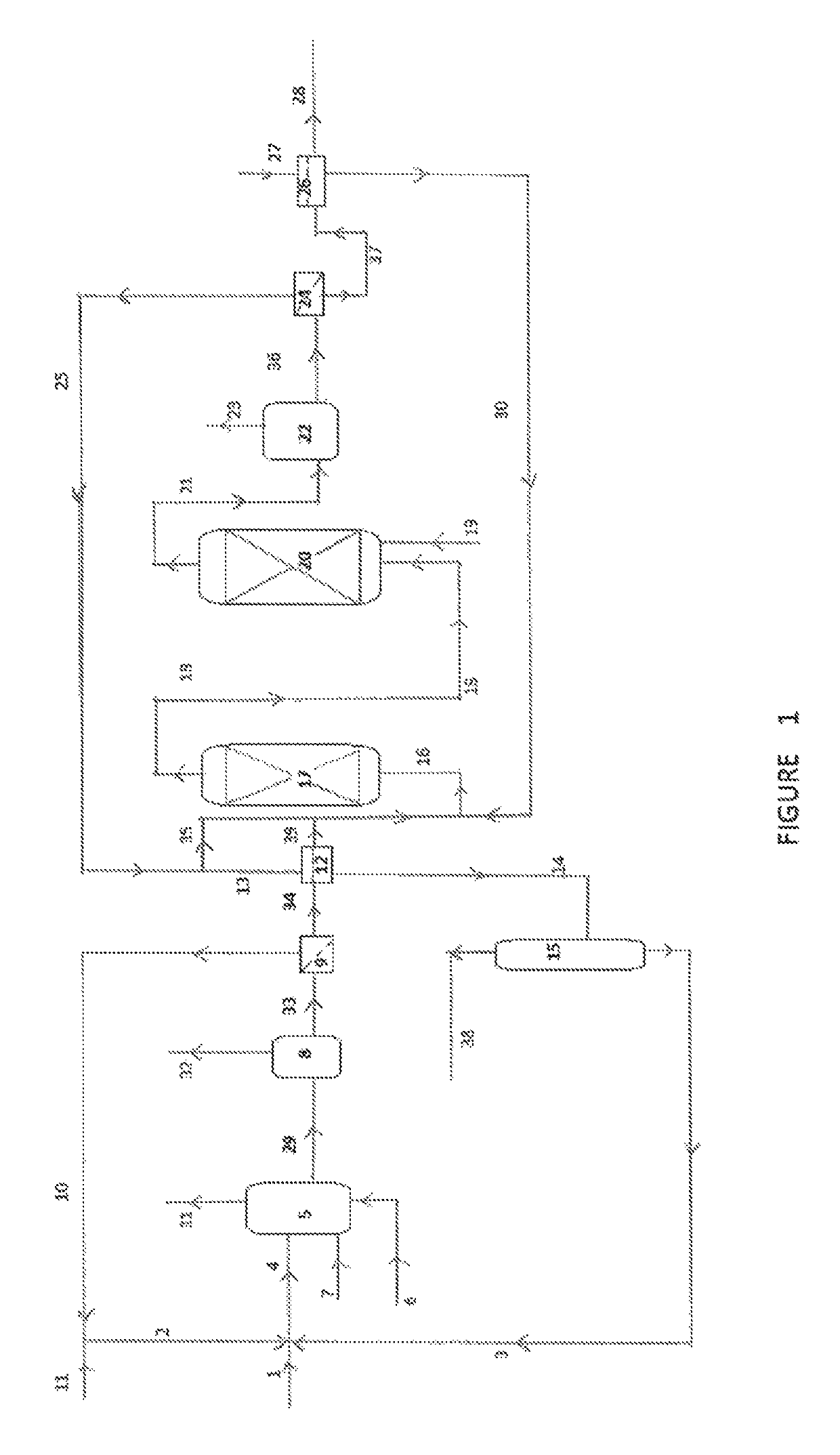

Purifying crude furan 2,5-dicarboxylic acid by hydrogenation and a purge zone

ActiveUS20160311790A1Lower energy requirementsImprove solubilityOrganic chemistrySolvent extractionFuranCarboxylic acid

A process for purifying a crude furan 2,5-dicarboxylic acid composition (cFDCA) by hydrogenation of a FDCA composition dissolved in a hydrogenation solvent such as water, and hydrogenating under mild conditions, such as at a temperature within a range of 130° C. to 225° C. by contacting the solvated FDCA composition with hydrogen in the presence of a hydrogenation catalyst under a hydrogen partial pressure within a range of 10 psi to 900 psi. A product FDCA composition is produced having a low amount of tetrahydrofuran dicarboxylic acid, a low b*, and a low amount of 5-formyl furan-2-carboxylic acid (FFCA).

Owner:EASTMAN CHEM CO

Process of selectively hydrogenating and desulfurizing inferior gasoline

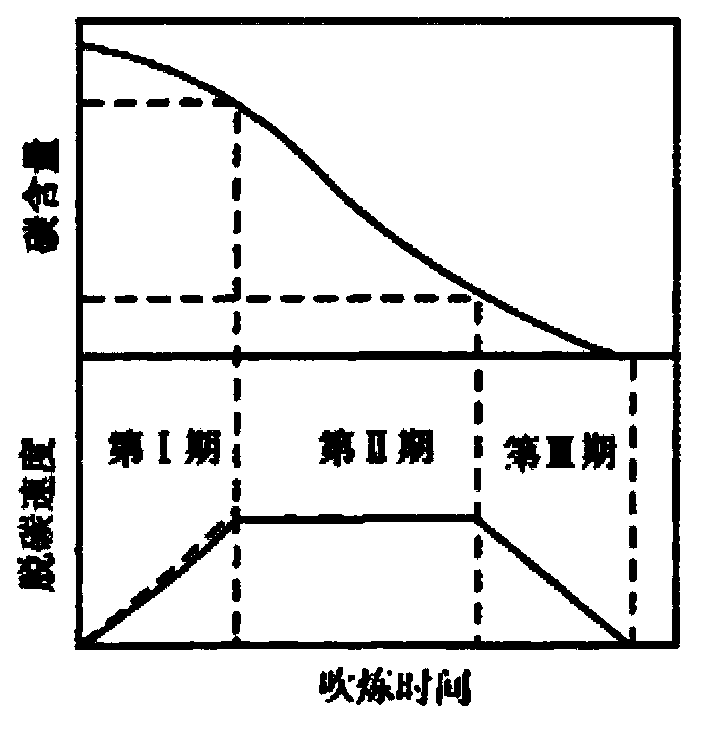

ActiveCN101089129AIncrease temperatureReduce dosageRefining to eliminate hetero atomsLow activityHydrodesulfurization

The process of selectively hydrogenating and desulfurizing inferior gasoline includes selectively hydrogenating and desulfurizing inferior gasoline, separating oil from gas, eliminating mercaptan and other steps. In the step of selectively hydrogenating and desulfurizing inferior gasoline, one kind of high activity hydrogenating and desulfurizing catalyst in the upstream and one kind of low activity hydrogenating and desulfurizing catalyst in the downstream are applied. The hydrogenating and desulfurizing has the great amount of heat produced in the hydrogenating and desulfurizing reaction well utilized, so that the present invention has lowered hydrogen consumption, high heat efficiency, prevention of over hydrogenation, inhibition of saturating hydrogenation of olefin and lowered octane value loss.

Owner:CHINA PETROLEUM & CHEM CORP +1

Purifying crude furan 2,5-dicarboxylic acid by hydrogenation

ActiveUS20140364633A1Lower energy requirementsImprove solubilityOrganic chemistryFuranDicarboxylic acid

A process for purifying a crude furan 2,5-dicarboxylic acid composition (cFDCA) by hydrogenation of a FDCA composition dissolved in a hydrogenation solvent such as water, and hydrogenating under mild conditions, such as at a temperature within a range of 130° C. to 225° C. by contacting the solvated FDCA composition with hydrogen in the presence of a hydrogenation catalyst under a hydrogen partial pressure within a range of 10 psi to 900 psi. A product FDCA composition is produced having a low amount of tetrahydrofuran dicarboxylic acid, a low b*, and a low amount of 5-formyl furan-2-carboxylic acid (FFCA).

Owner:EASTMAN CHEM CO

Purifying crude furan 2,5-dicarboxylic acid by hydrogenation and a purge zone

ActiveUS9944615B2Lower energy requirementsImprove solubilityOrganic chemistryLiquid solutions solvent extractionFuranDicarboxylic acid

Owner:EASTMAN CHEM CO

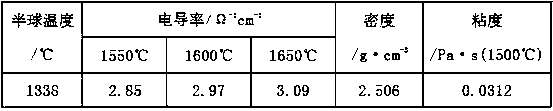

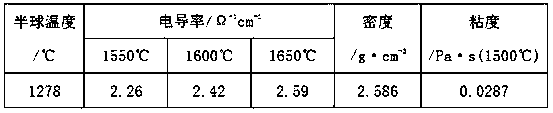

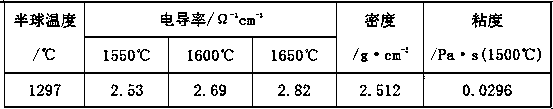

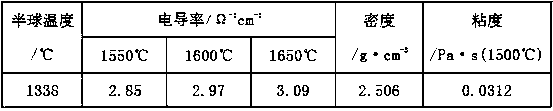

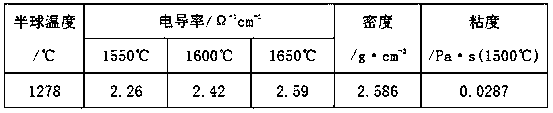

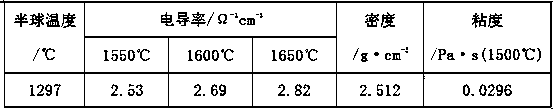

Composite molten steel slag washing agent based on LF (ladle furnace) refining waste slag and preparation method thereof

The invention discloses a composite molten steel slag washing agent based on LF (ladle furnace) refining waste slag and a preparation method thereof. The composite molten steel slag washing agent consists of 65 to 95% of LF refining slag, 10 to 30% of active lime and 5 to 15% of industrial soda. The LF refining slag is composed of 50 to 60% of CaO, 25 to 35% of Al2O3, 4 to 8% of SiO2, 4 to 7% of MgO, 0.5 to 1.0% of MnO and FeO, 0.005 to 0.02% of P2O5, and 0.01 to 0.3% of S; the active lime includes 90 to 94% of CaO, and HCl with activity of 350 to 380 ml / 4N and granularity of 0.5 to 3.0 mm; and the industrial soda includes 99.2% of Na2CO3 with granularity of 0.5 to 1.0 mm. The preparation method comprises the following steps of: processing the LF refining slag and the active lime into the powder with the granularity of 0.5 to 3.00 mm; uniformly mixing and stirring the materials according to the percentage, dry-pressing and moulding the materials with granularity of 25 to 35 mm and applying the waterproof packaging to the materials. On the condition that the adding quantity is 4 to 6 kg / t, the desulfurization rate of the invention achieves more than 30%, the reduction rate of the total oxygen content is more than 25% and the qualified rate of the thermal top forge is improved from 80% to 95%, so that the invention realizes the resource recycling of the LF refining waste slag and is beneficial to the energy-saving and emission reduction of the iron and steel enterprises.

Owner:NANJING IRON & STEEL CO LTD +1

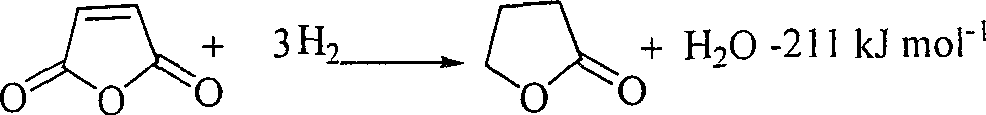

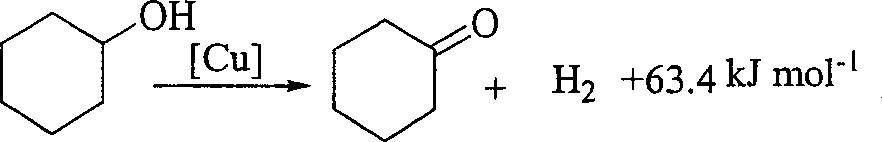

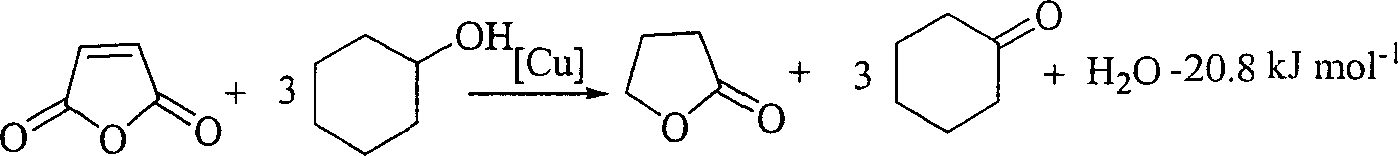

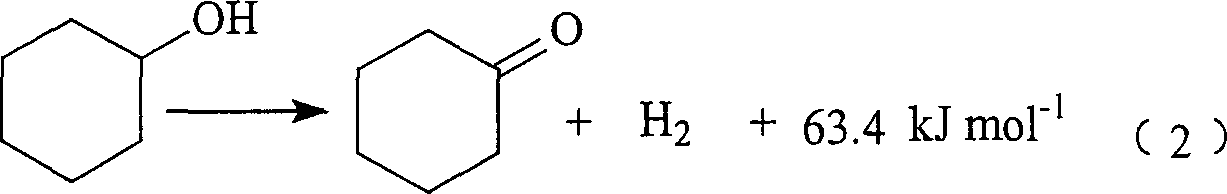

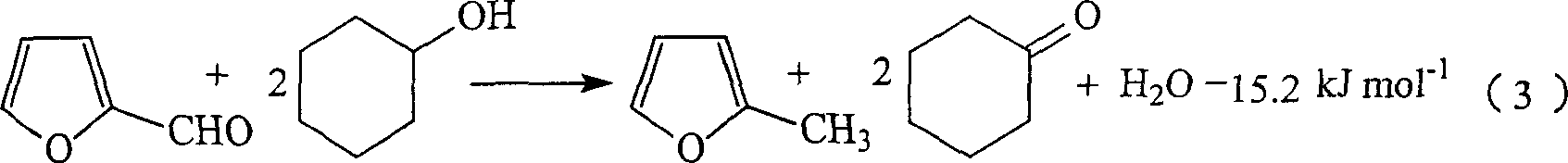

Method for preparing gamma-butyrolactone and cyclohexanone by couple process

InactiveCN1789255AAvoid hydrogenationCan mitigate thermal effectsEnergy inputCarbonyl compound preparation by oxidationCyclohexanoneHydrogen

A coupling method for preparing ª†-butyrolactone and cyclohexanone, carrying out integral reaction with the mixture of cyclohexanol and anhydride under the condition of gas phase, existence of additional hydrogen or no additional hydrogen, proper temperature and hydrogen catalyst. The invention is characterized compared with current technology by the integral reaction of hydrogenation and dehydrogenation, low energy consumption, no need for hydrogenation or hydrogen recovery, low producing cost, high selectivity and recovery rate, simple preparing process and easy-to-operate.

Owner:SYNEFUELS CHINA

Multipurpose environment-friendly cleaning paste and preparation method thereof

InactiveCN102787036AStrong detergencyRemove dust wellNon-ionic surface-active compoundsSurface-active non-soap compounds and soap mixture detergentsChemistryWater soluble

The invention provides a multipurpose environment-friendly cleaning paste and a preparation method thereof. The multipurpose environment-friendly cleaning paste comprises, by weight, 5-15% of stearic acid, 4-10% of palm oil, 4-10% of coconut oil, 0.8-2% of sodium hydroxide, 0.1-0.5% of potassium hydroxide, 0.2-0.8% of soda ash, 0.8-2% of peregal O, 0.8-2% of tween-20, 0.8-2% of tween-80, 5-15% of carnauba wax, 15-20% of water-soluble silicone oil, 8-15% of OP-10, 0.2-0.8% of preservative, 0.1-0.5% of essence and 20-45% of purified water. The multipurpose environment-friendly cleaning paste has the unique advantages of being green, environment-friendly, free of corrosion and foreign smell and strong in detergency, sterilizing, polishing, waxing and saving water and time. Besides, the multipurpose environment-friendly cleaning paste removes dust, leaves no trace and is long in duration time, simple to manufacture, practical and simple and convenient to operate and use.

Owner:何全东

Catalyst system for preparing cyclohexene by benzene selective hydrogenation, and method for preparing cyclohexene by benzene selective hydrogenation by catalyzing with catalyst system

ActiveCN102744084ASolve the cumbersome process of preparing catalystsSolve the characteristicsHydrocarbon by hydrogenationOrganic-compounds/hydrides/coordination-complexes catalystsAlkaline earth metalCyclohexene

The invention relates to a catalyst system for preparing cyclohexene by benzene selective hydrogenation, and a method for preparing cyclohexene by benzene selective hydrogenation. The method for preparing cyclohexene by benzene selective hydrogenation is implemented by catalyzing with the catalyst system composed of nanometer Ru catalyst, alkaline substance M, zinc salt and water. The nanometer Ru catalyst with microcrystalline size of 3-6 nm is prepared from NaOH, RuCl3 and polyethylene glycol (PEG) by co-current co-precipitation method. The alkaline substance M can be hydroxide, oxide or alkaline organic substance of alkali metal, alkaline earth metal, transition metal or rare earth metal. The zinc salt can be zinc sulfate, zinc nitrate or zinc chloride. Ru catalyst / M / zinc salt weight ratio is 1:(0-10):(20-30), and Ru / water weight ratio is 0.5-1%. At 150 DEG C and 5.0 MPa, after reaction for 15-25 min, when the benzene conversion rate is 40-60%, cyclohexene selectivity is 75-85%, and cyclohexene yield is 35-50%.

Owner:ZHENGZHOU UNIV

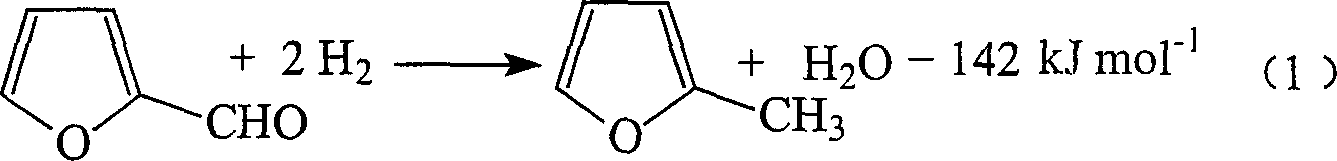

Preparation of 2-methylfuran and cyclohexanone by couple method

InactiveCN1789256ACan mitigate thermal effectsSave energyEnergy inputCarbonyl compound preparation by oxidationCyclohexanoneHydrogen

A coupling method for preparing 2-methylfuran and cyclohexanone, carrying out integral reaction with the mixture of furfuraldehyde and anhydride under the condition of gas phase, existence of additional hydrogen or no additional hydrogen, proper temperature and hydrogen catalyst. The invention is characterized by the low energy consumption, no need for hydrogenation or hydrogen recovery, low producing cost, high selectivity and productivity, simple preparing process and easy-to-operate.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

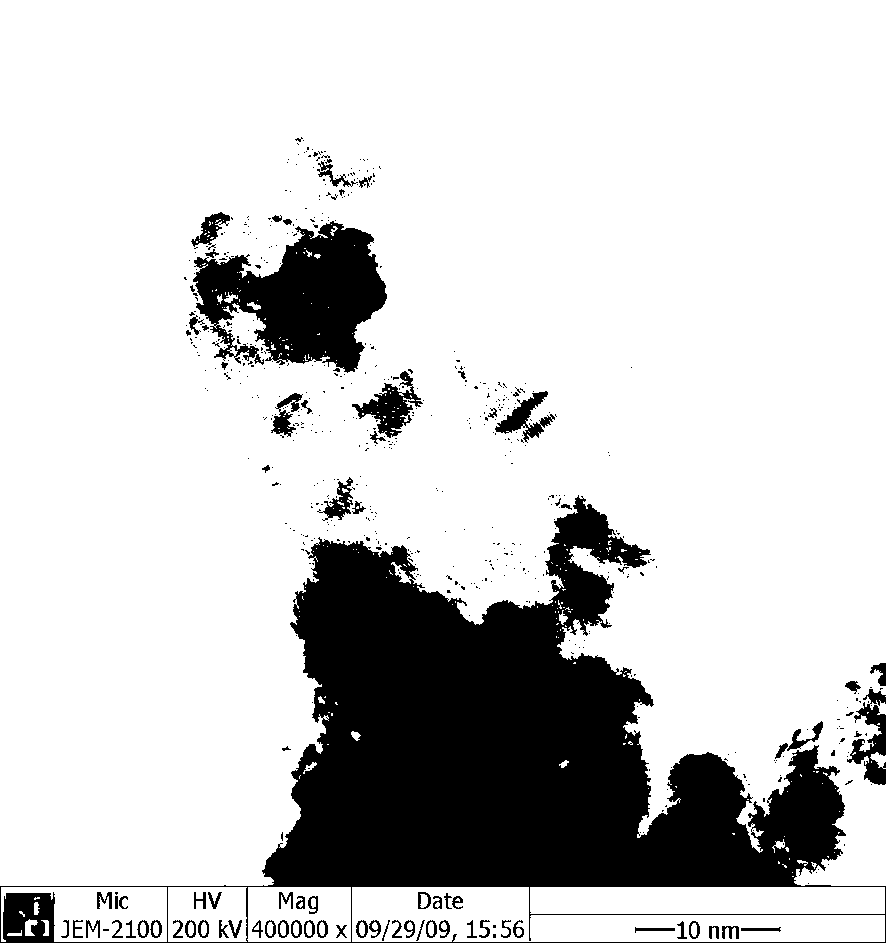

Preparation of core-shell catalyst of cyclohexene by efficient benzene hydrogenation

PendingCN109794236AHigh selectivityImprove stabilityHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsBenzeneMass transfer resistance

The invention discloses a preparation method of a bi-functional catalyst of a (Ru / MeOx)@MeOx core-shell structure. The method is characterized in that a center suitable for surface catalyzing is formed by core phase Ru / MeOx and shell phase m-MeOx. A ruthenium-based catalyst prepared by the method has high dispersing performance, so that benzene is dissociated and absorbed more easily at a lower temperature to improve the conversion rate of the benzene;the cyclohexene is allowed to be desorbed on a shell by a hydrophilic m-MeOx shell phase to prevent further hydrogenation and improve the selectivity of the cyclohexene, the loss of activated species can be reduced by the core-shell structure to allow the catalyst to be more stable, the mass transfer resistance can be reduced, the excellent composite performance can be applied to part of hydrogenation cyclohexene reaction of benzene, and extremely high selectivity and yield are obtained. The preparation method is simple, the conditions are mild, the repeating is easy, and the method is suitable for large-scale industrial production.

Owner:FUZHOU UNIV

Rubber composition, crosslinkable rubber composition and crosslinked articles

A rubber composition comprising (1) a diene rubber, (2) a highly saturated rubber, and (3) a block copolymer that comprises a diene polymer block A and a hydrogenated diene polymer block B and has a primary structure selected from the following structures: (A-B)X, (A-B)X-A, and B-(A-B)X (wherein X is an integer of 1 or above) wherein the rubber composition contains 0.1 to 25 parts by mass of the block copolymer (3) with respect to 100 parts by mass of the total amount of the diene rubber (1) and the highly saturated rubber (2). Such a rubber composition exhibits improved dispersibility between its rubber components, i.e., diene rubber and highly saturated rubber, and improved adhesion at the interface between the rubber phases. The rubber composition also shows high tensile property as well as high flexing property.

Owner:KURARAY CO LTD

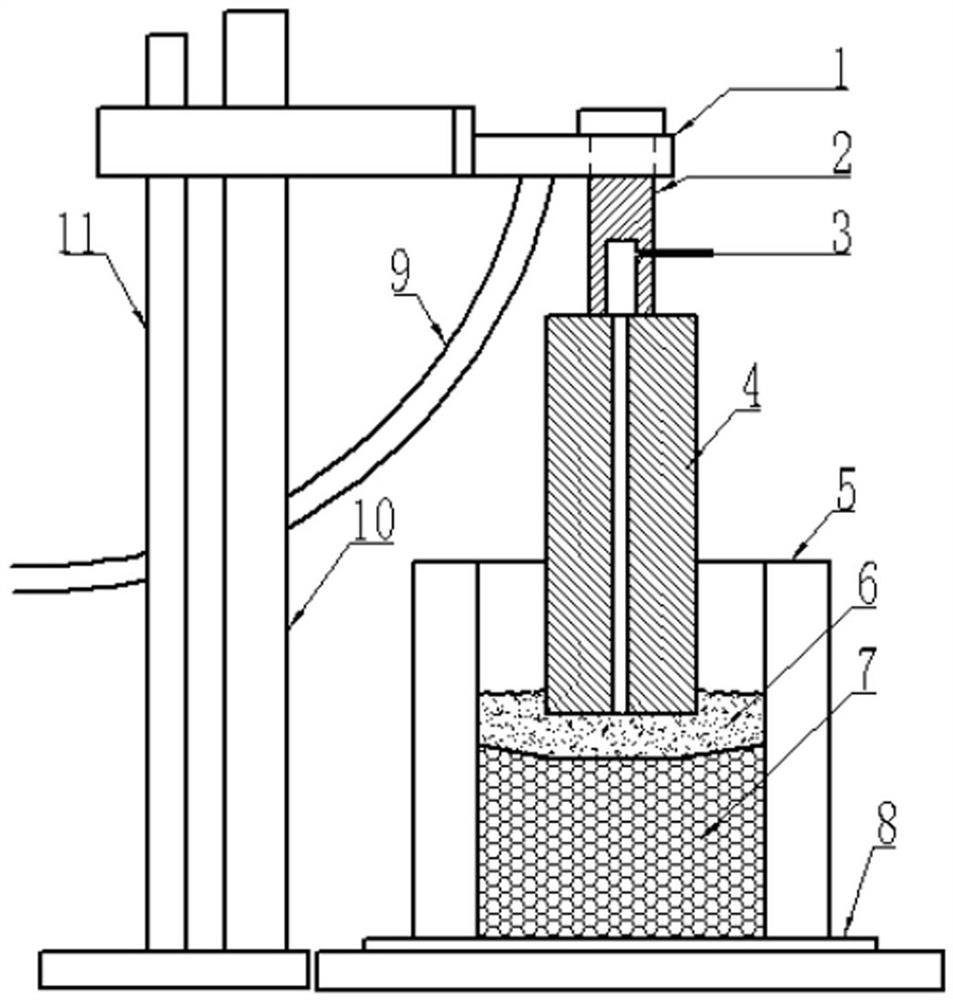

Production method for pre-melted slag for small-batch electroslag remelting

ActiveCN108034834ARealize the production of premelted slag for remeltingAchieve productionSlagCrusher

The invention discloses a production method for pre-melted slag for small-batch electroslag remelting. The production method comprises the steps that firstly, a slag melting bag with the volume being300 kg is selected and used; secondly, pre-melted slag raw materials are taken to be preheated and baked in a slag baking furnace; thirdly, the baked pre-melted slag raw materials with the weight being smaller than or equal to 300 kg in the second step are placed in the slag melting bag in the first step, a double-pole series connection electroslag furnace is used for arc strike for slag melting in the slag melting bag, and after slag melting is over, the slag liquid is poured into a steel tank to be cooled and solidified; and fourthly, slag blocks solidified in the third step are crushed through a small crusher, and the slag blocks serve as pre-melted slag for electroslag remelting after being weighed. The double-pole series connection electroslag furnace is utilized for slag melting in the slag melting bag, production of small-batch pre-melted slag with the weight being smaller than or equal to 300 kg is achieved, and the problem that pre-melted slag for the small-batch test steel grade is hard to produce and purchase is solved. The method is simple, convenient to use and worthy of popularization and application.

Owner:XINGTAI IRON & STEEL

Process for the preparation of a purified acid composition

ActiveUS10351544B2Increase productionEasy to separateOrganic reductionOrganic compounds purification/separation/stabilisationFuranHydrogen

A purified acid composition including 2,5-furandicarboxylic acid is prepared by a process including a) providing an acid composition solution of a crude acid composition in a polar solvent, the crude acid composition including 2,5-furandicarboxylic acid (FDCA) and 2-formyl-furan-5-carboxylic acid (FFCA); b) contacting the acid composition solution with hydrogen in the presence of a hydrogenation catalyst to hydrogenate FFCA to hydrogenation products, such that the hydrogenation products contain a minor amount of 2-methyl-furan-5-carboxylic acid (MFA) or no MFA, yielding a hydrogenated solution; c) separating at least a portion of the FDCA from the hydrogenated solution by crystallization.

Owner:FURANIX TECH BV

Production method for effectively controlling gas content in beam blank

InactiveCN103361460BSolve storage problemsEffective control of hydrogen additionManufacturing convertersSlagHydrogen content

The invention relates to a production method for effectively controlling gas content in beam blank. The production method comprises processes of raw material pre-treating, converter smelting, deoxidation alloying, and refining, wherein the materials maintain dry, the process of adding slag charge is moved forward to avoid adding material operation 3 minutes before the terminal point; the process of modifying converter slag is moved backward, synthesis slag is added on top of the steel slag after the converter furnace has been stocked with steels other than going into the converter furnace with the steel water, synthesis slag is subjected to a ultra-high-temperature baking by utilizing the steel slag to maximumly reduce the water in the synthesis slag and the crystal water contained by the synthesis slag; electrode powder replaces carbon powder to match with carbon in the refining process to reduce the effect of carbon matching on molten steel hydrogenation. The production method can effectively control hydrogen addition in production process, reduces the hydrogen content in molten steel, makes the hydrogen content in the steel stay in a range of 1 to 3 ppm, reduces casting blank pinhole defects, and improves casting blank yield rate.

Owner:LAIWU IRON & STEEL GRP

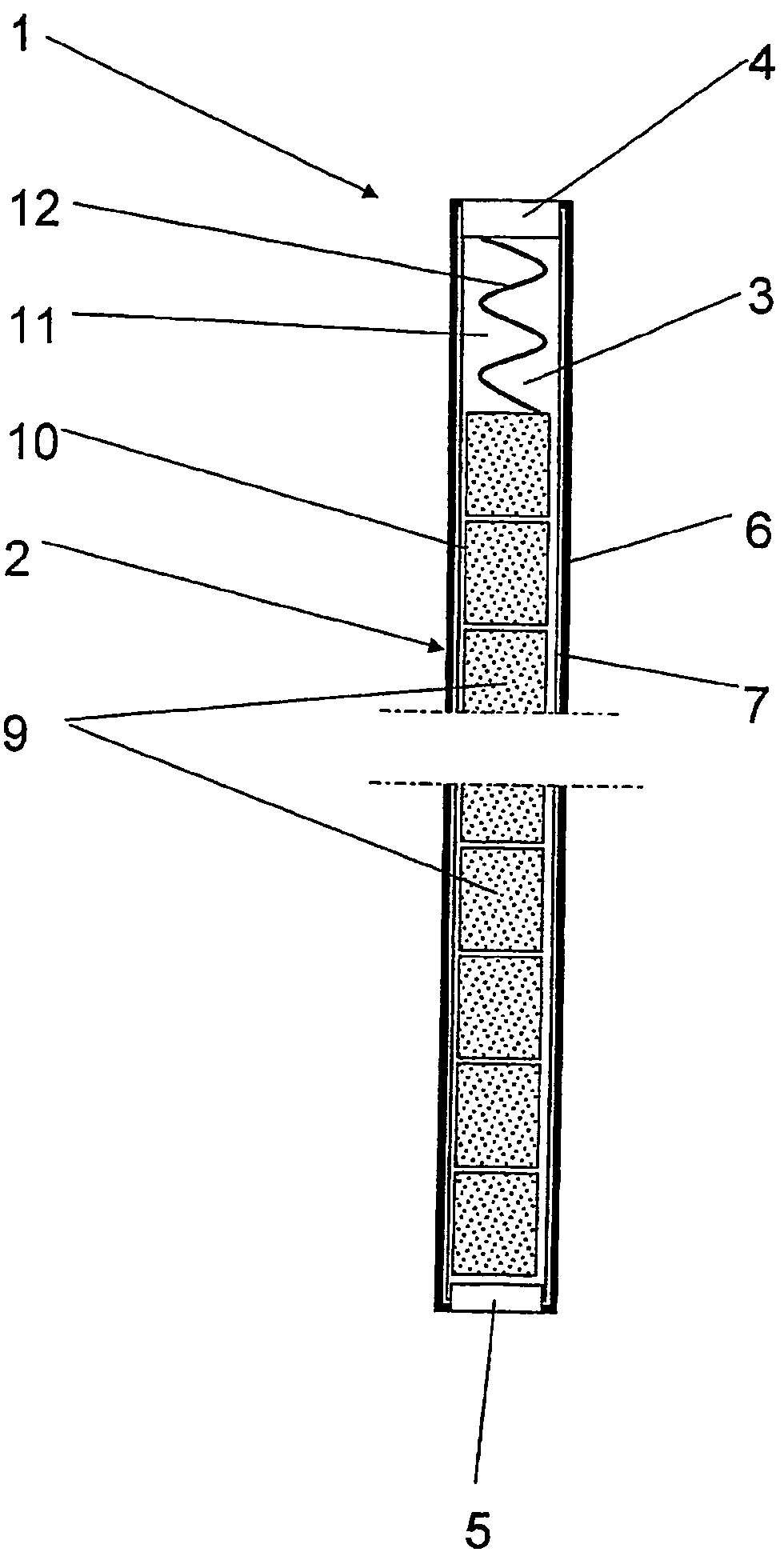

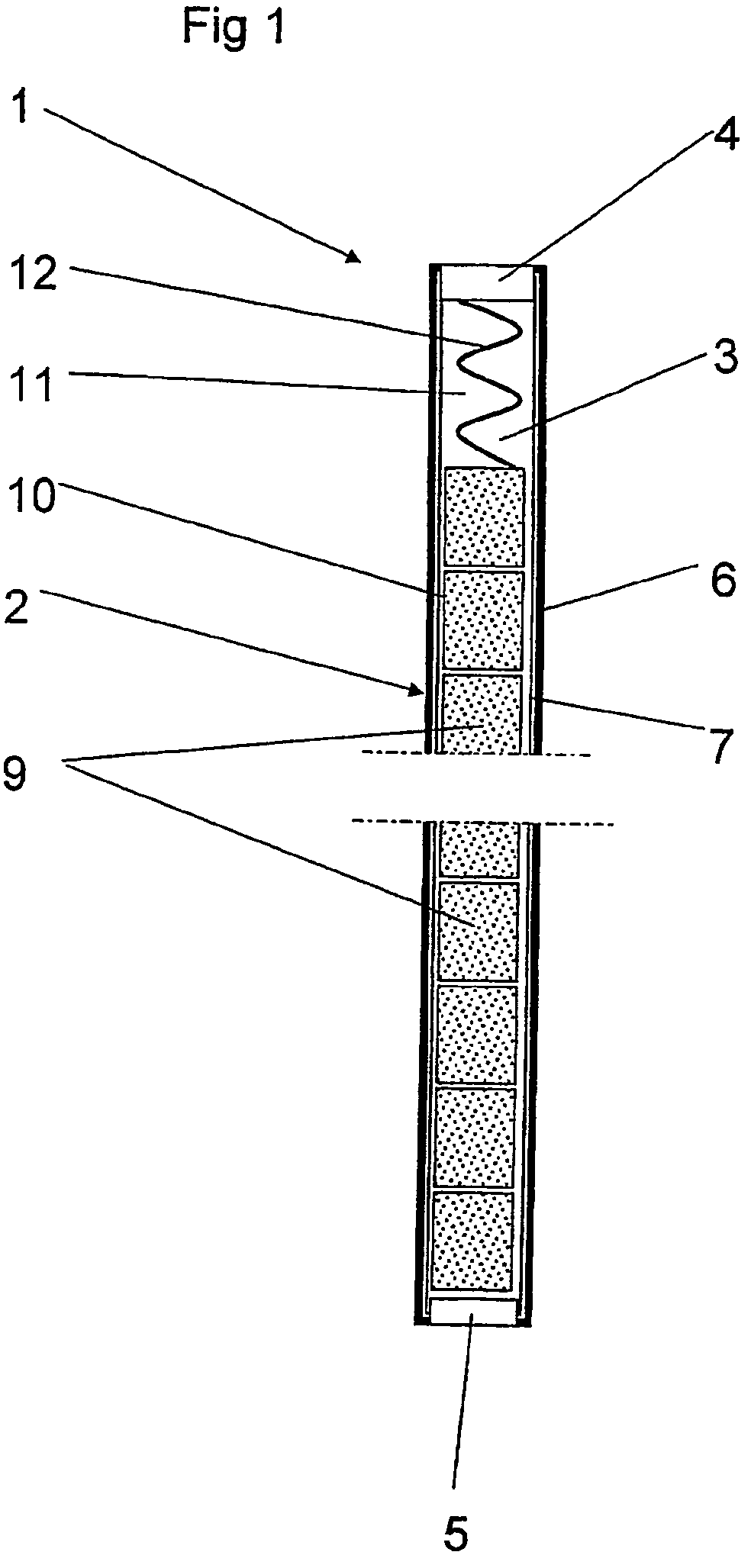

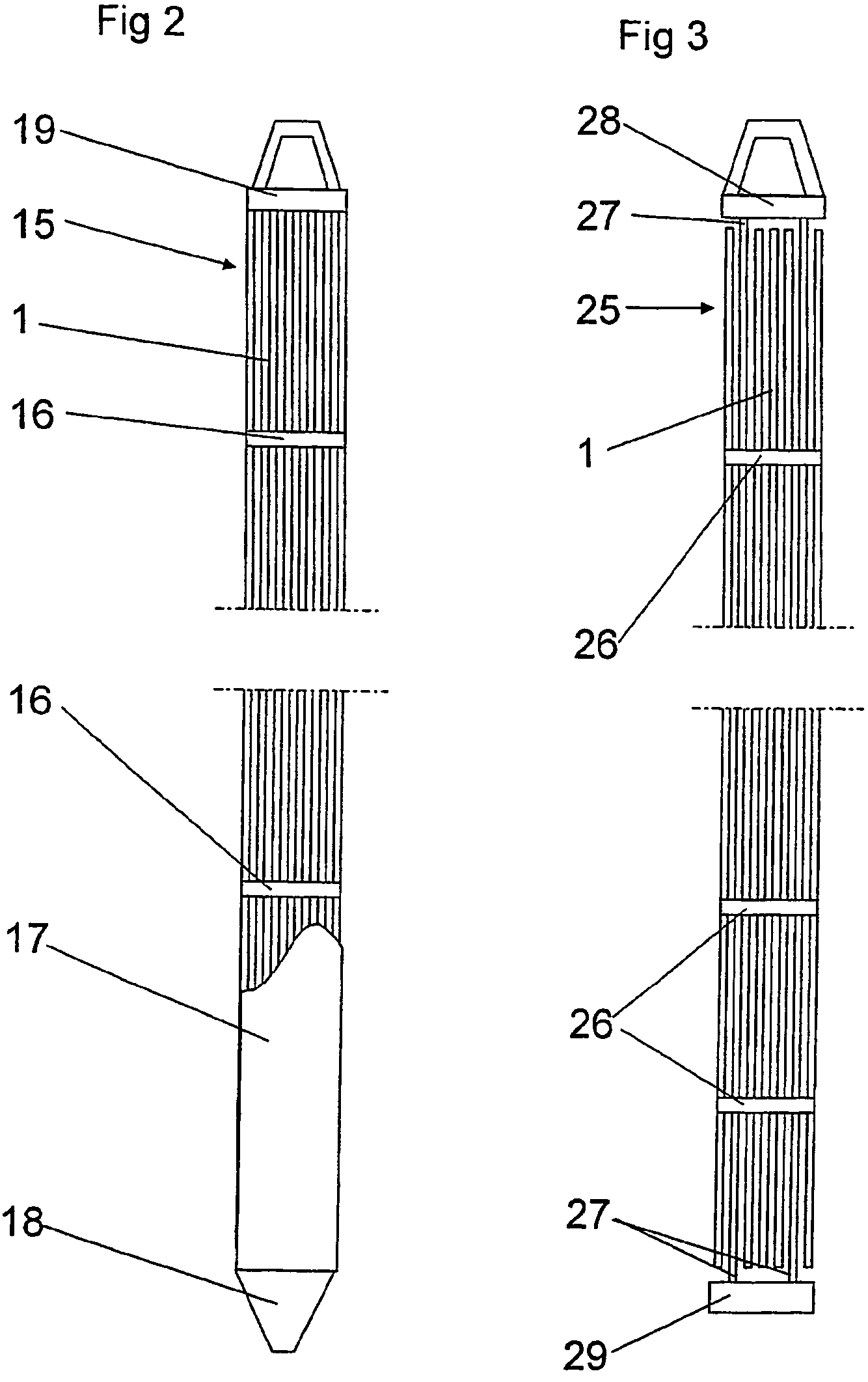

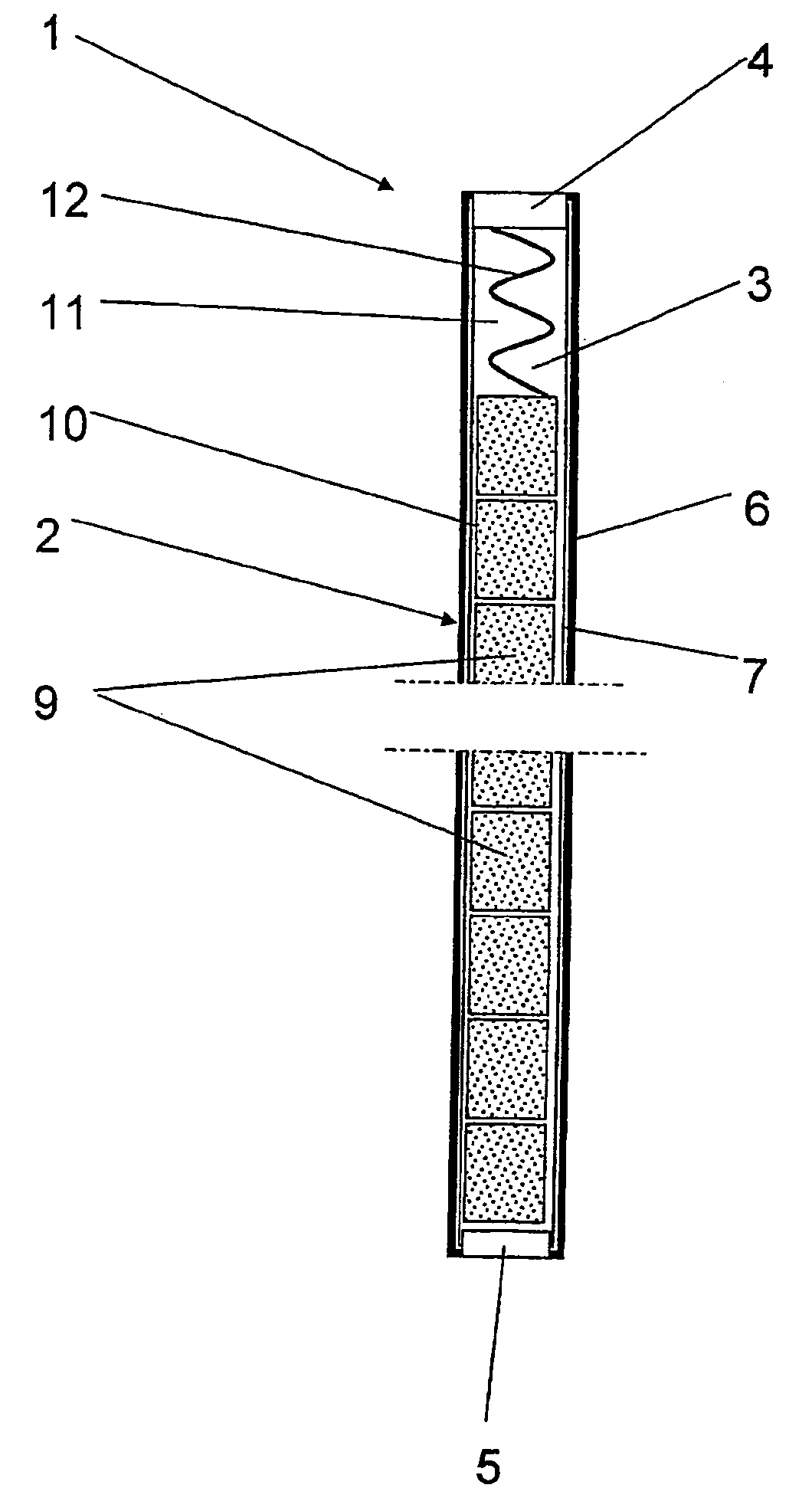

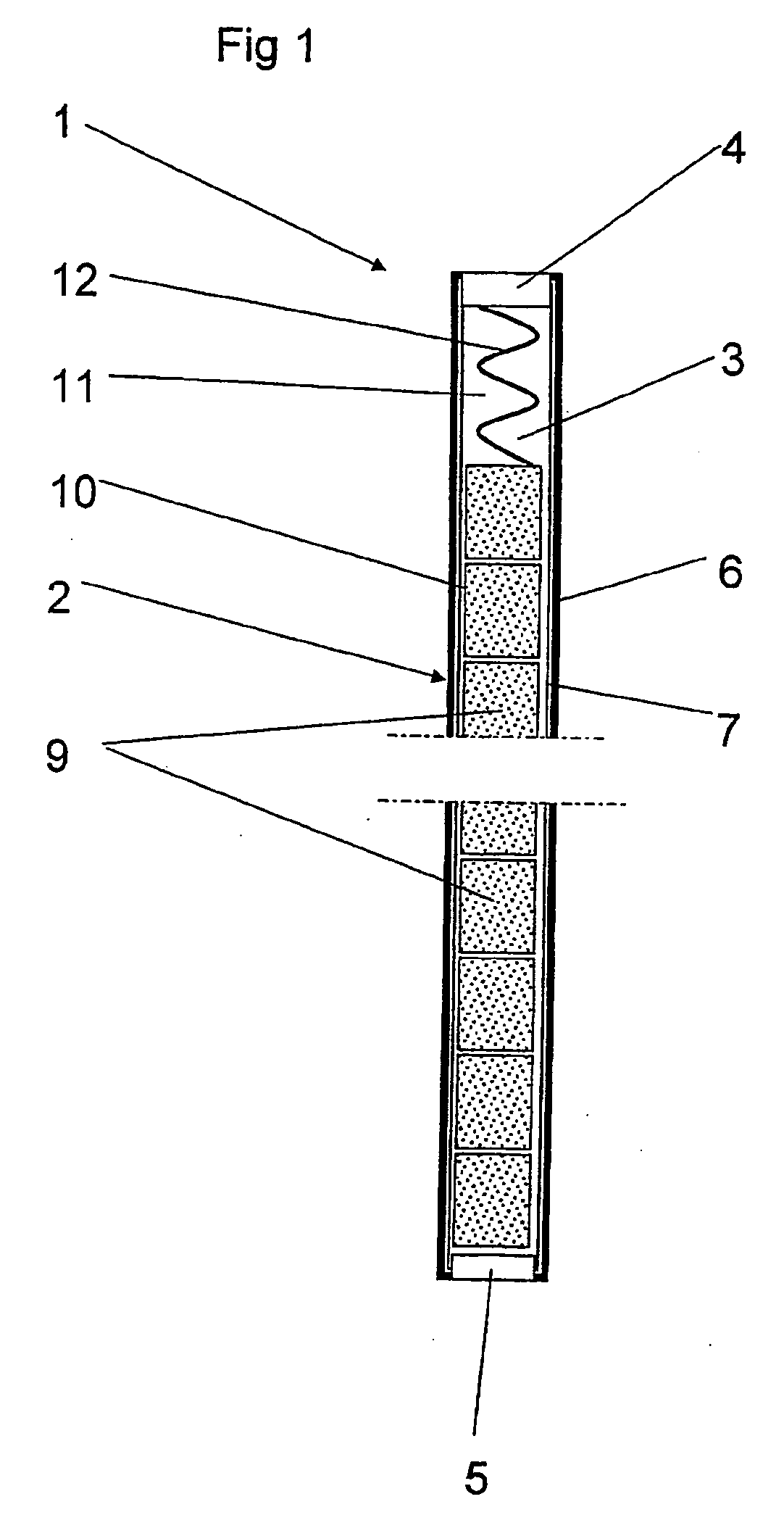

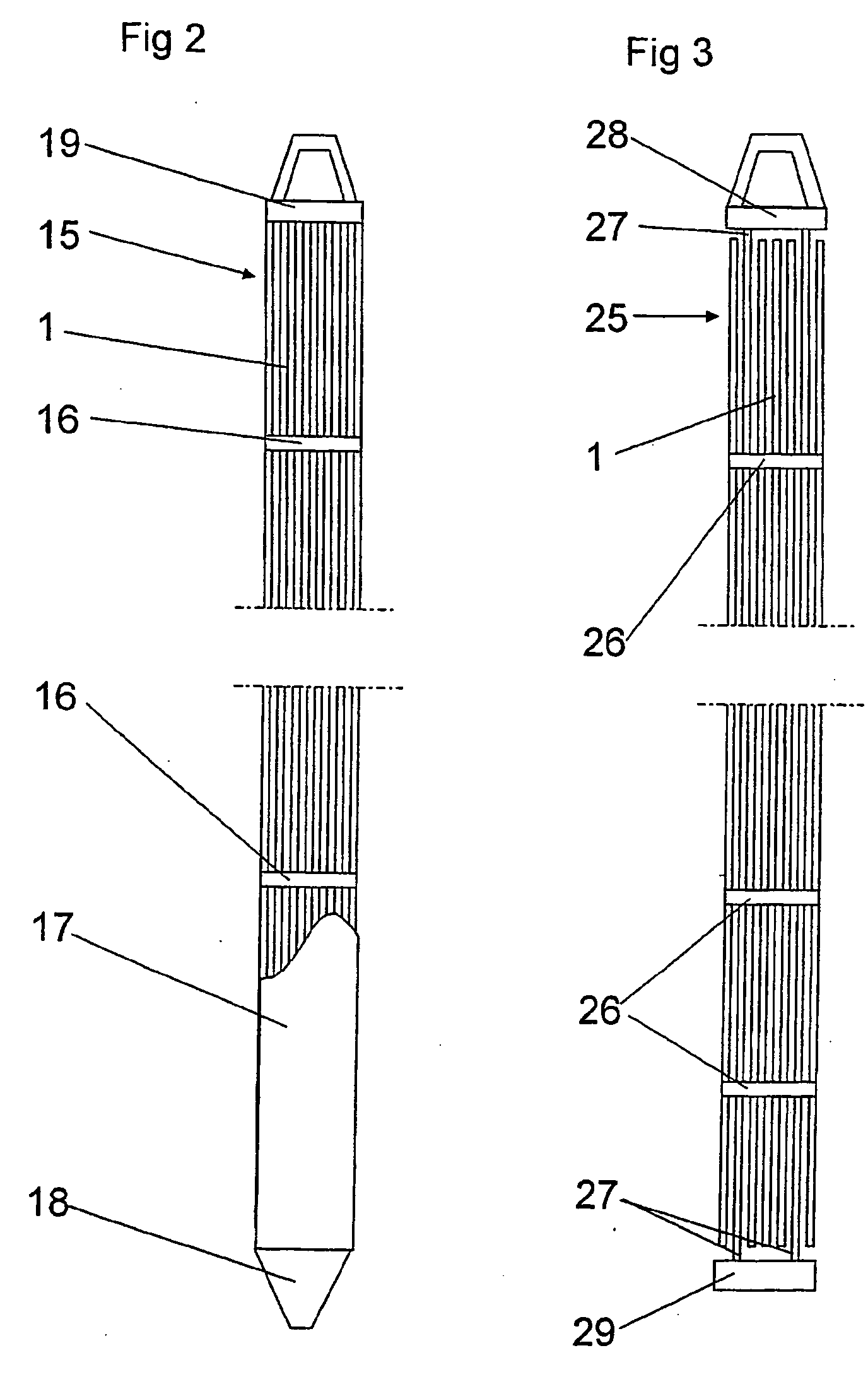

Nuclear fuel rod

ActiveUS7570728B2Improve a nuclear fuel rod's resistability against secondary degradingAvoid hydrogenationFuel elementsNuclear energy generationInternal pressureAlloy

In a nuclear fuel rod a cladding tube is provided having a closed inner space and manufactured from at least one of the materials in the group zirconium and a zirconium-based alloy, and a pile of nuclear fuel pellets arranged in the inner space in the cladding tube. The nuclear fuel pellets fill part of the inner space. A fill gas is arranged in the closed inner space to fill the rest of the inner space. The internal pressure of the fill gas in the nuclear fuel rod amounts to at least 2 bar (abs) or at least 10 bar (abs). The fill gas contains a proportion of inert gas a proportion of carbon monoxide that is greater than 3 volume percent of the fill gas or greater than 2 volume percent of the fill gas.

Owner:WESTINGHOUSE ELECTRIC SWEDEN

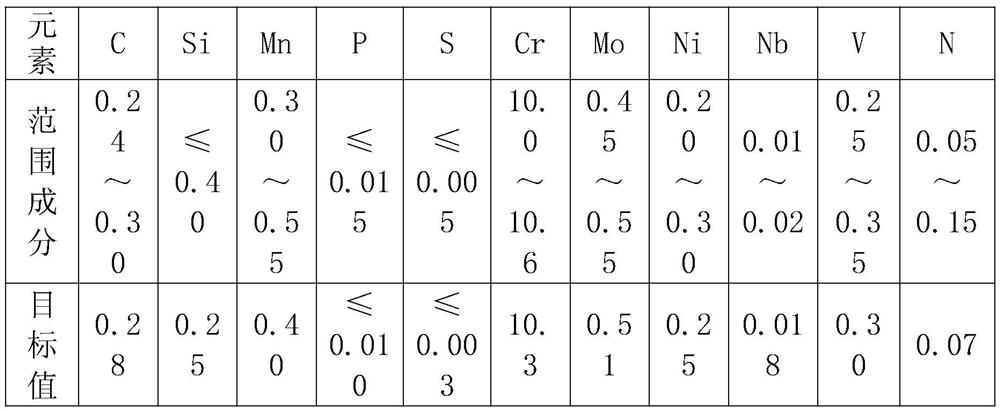

Nitrogen-filling electroslag process for cavity of nitrogen-containing steel hollow blank

The invention particularly relates to a nitrogen-filling electroslag process for a cavity of a nitrogen-containing steel hollow blank, which is different from a common process in which nitrogen is added into an electrode blank of nitrogen-containing steel and then electroslag is carried out. The process is characterized in that nitrogen is not added during smelting of an electrode blank, a nitrogen-free hollow electrode blank is adopted, nitrogen is injected from a reserved hole during electroslag, nitrogen is added into steel through the physical and chemical reaction of nitrogen and steel slag, the nitrogen flow is controlled according to the nitrogen content of different steel types, and alloying of the nitrogen element is completed in the electroslag remelting process. The process can be applied to common electroslag equipment only, and a special pressurizing electroslag furnace high in price does not need to be arranged. Due to the fact that the blank is a hollow blank, the hot spot is not in the center of a molten pool, the shape of an electroslag molten pool is greatly improved, the molten pool tends to be in a flat state, the consistency of internal and external crystalline states of an ingot is higher, redundant nitrogen overflows from the periphery to form a protective atmosphere, oxygen increasing and hydrogen increasing of molten steel are avoided, the alloying target of the nitrogen element can be easily achieved, and the quality of the electroslag ingot can be improved.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

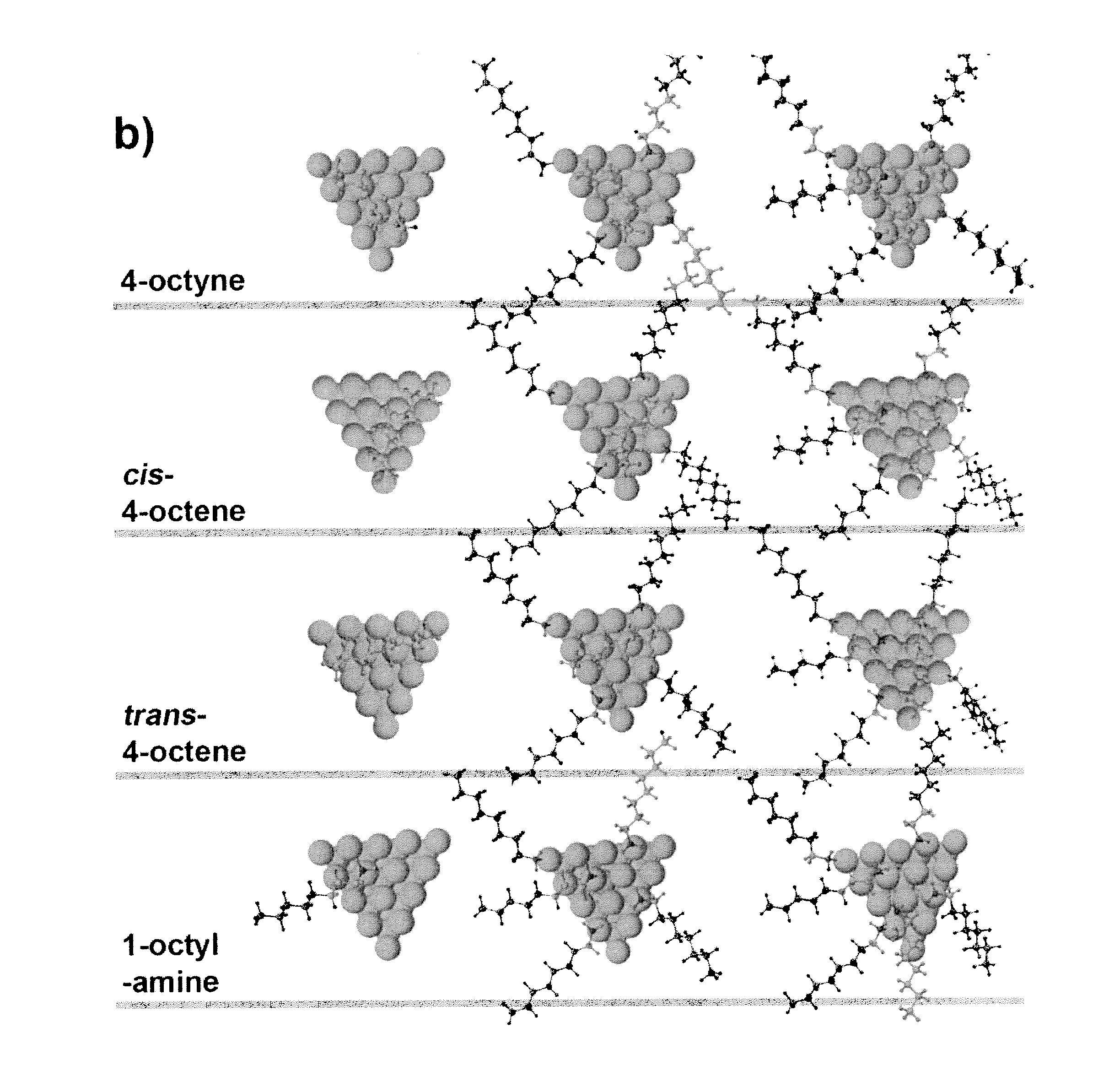

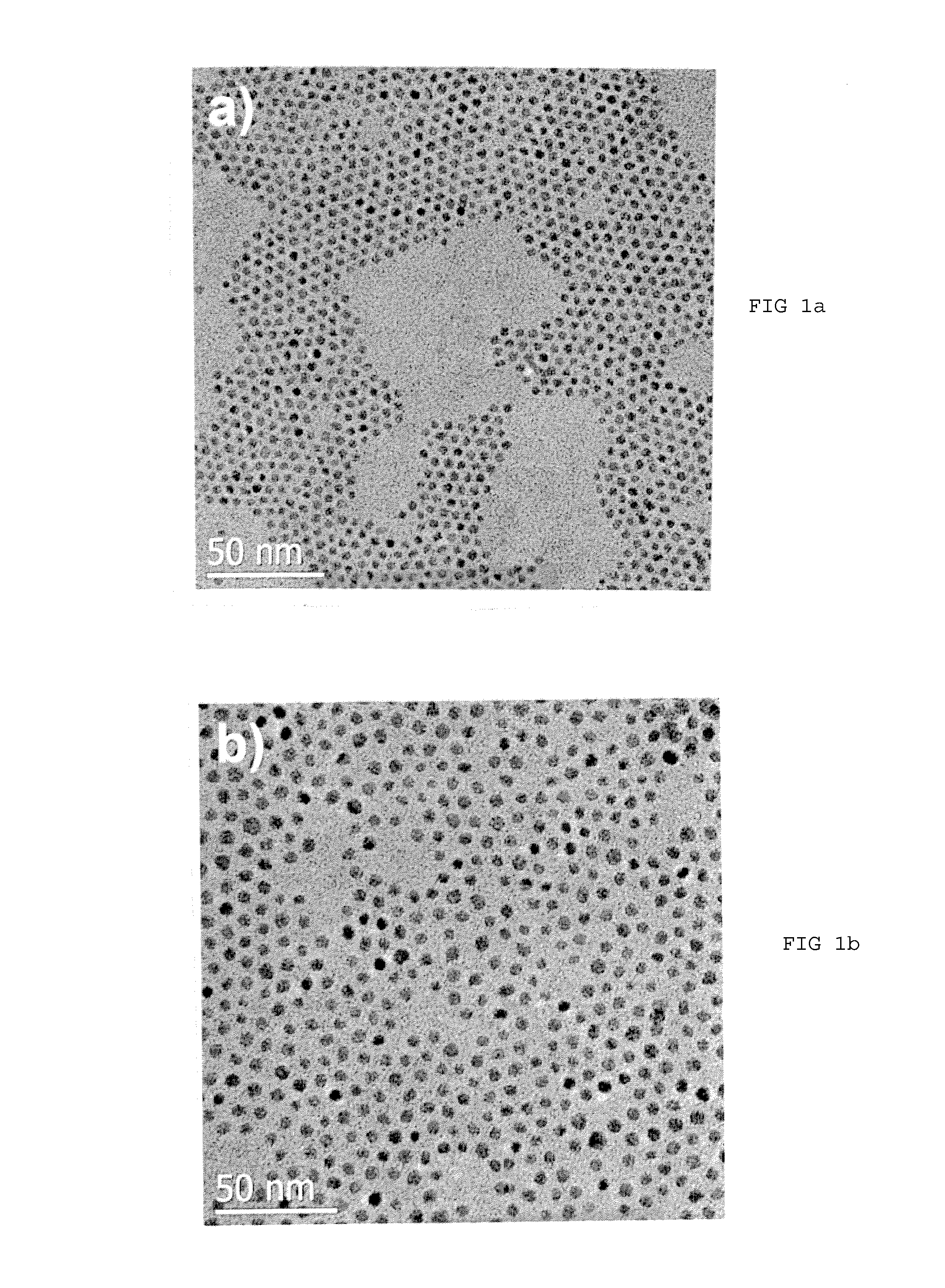

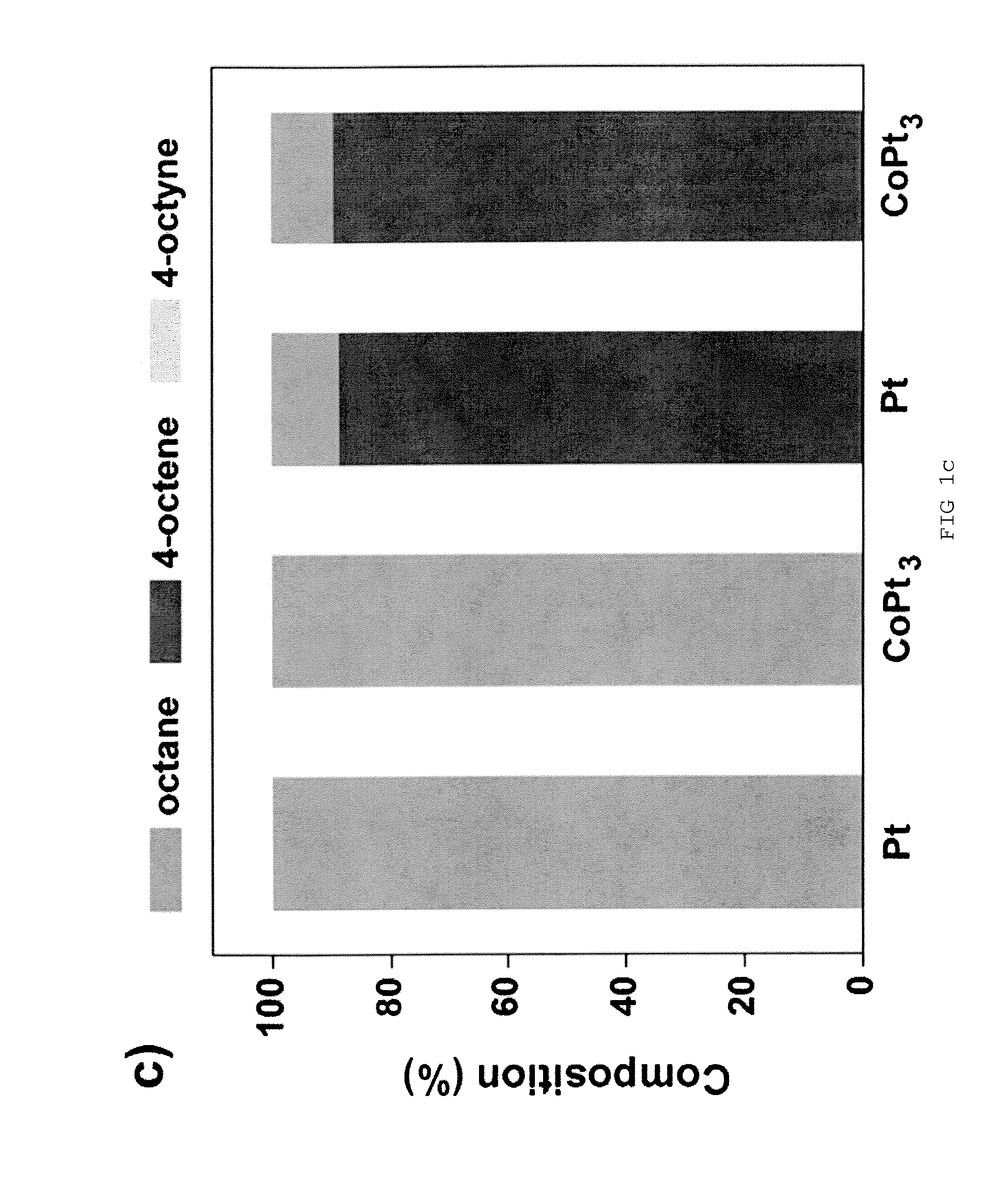

Surface modification of catalystic surface by organic molecules and metal cations for selective catalysis

InactiveUS20140357910A1High selectivityLower binding energyHydrocarbon by hydrogenationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystHydrogenation reaction

An article and method of manufacture of a catalyst. The article includes a nanoparticle of a noble metal based on material with a primary alkylamine layer disposed on the surface of the nanoparticle catalyst. The alkylamine layer of at least about one monolayer establishes a minimum level of selectivity for hydrogenation reactions.

Owner:UCHICAGO ARGONNE LLC

Multipurpose environment-friendly cleaning paste and preparation method thereof

InactiveCN102787036BImprove the lubrication effectDefense against discolorationNon-ionic surface-active compoundsSurface-active non-soap compounds and soap mixture detergentsPotassium hydroxideStearic acid

The invention provides a multipurpose environment-friendly cleaning paste and a preparation method thereof. The multipurpose environment-friendly cleaning paste comprises, by weight, 5-15% of stearic acid, 4-10% of palm oil, 4-10% of coconut oil, 0.8-2% of sodium hydroxide, 0.1-0.5% of potassium hydroxide, 0.2-0.8% of soda ash, 0.8-2% of peregal O, 0.8-2% of tween-20, 0.8-2% of tween-80, 5-15% of carnauba wax, 15-20% of water-soluble silicone oil, 8-15% of OP-10, 0.2-0.8% of preservative, 0.1-0.5% of essence and 20-45% of purified water. The multipurpose environment-friendly cleaning paste has the unique advantages of being green, environment-friendly, free of corrosion and foreign smell and strong in detergency, sterilizing, polishing, waxing and saving water and time. Besides, the multipurpose environment-friendly cleaning paste removes dust, leaves no trace and is long in duration time, simple to manufacture, practical and simple and convenient to operate and use.

Owner:何全东

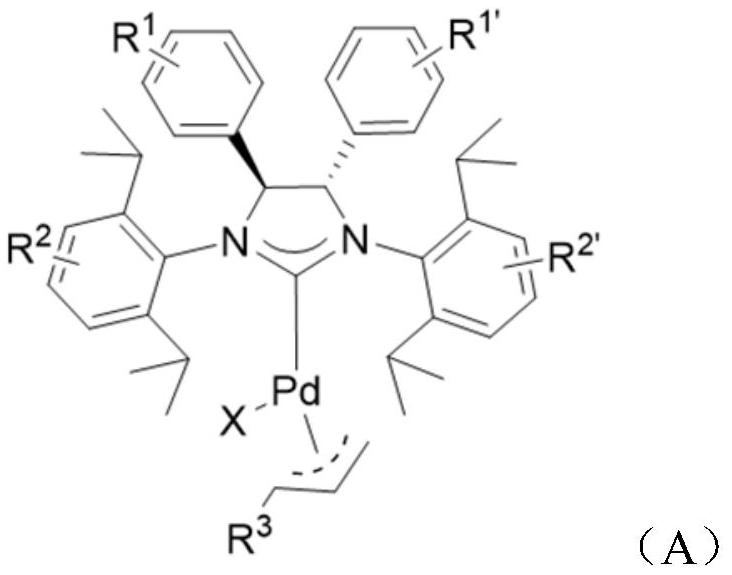

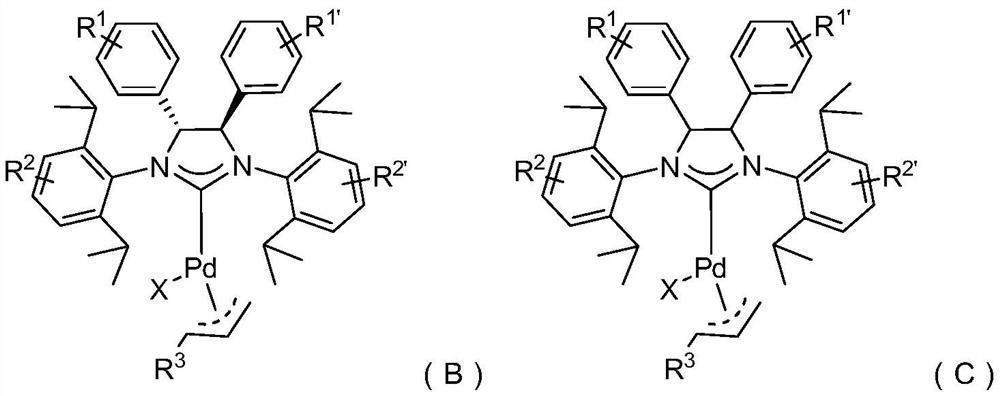

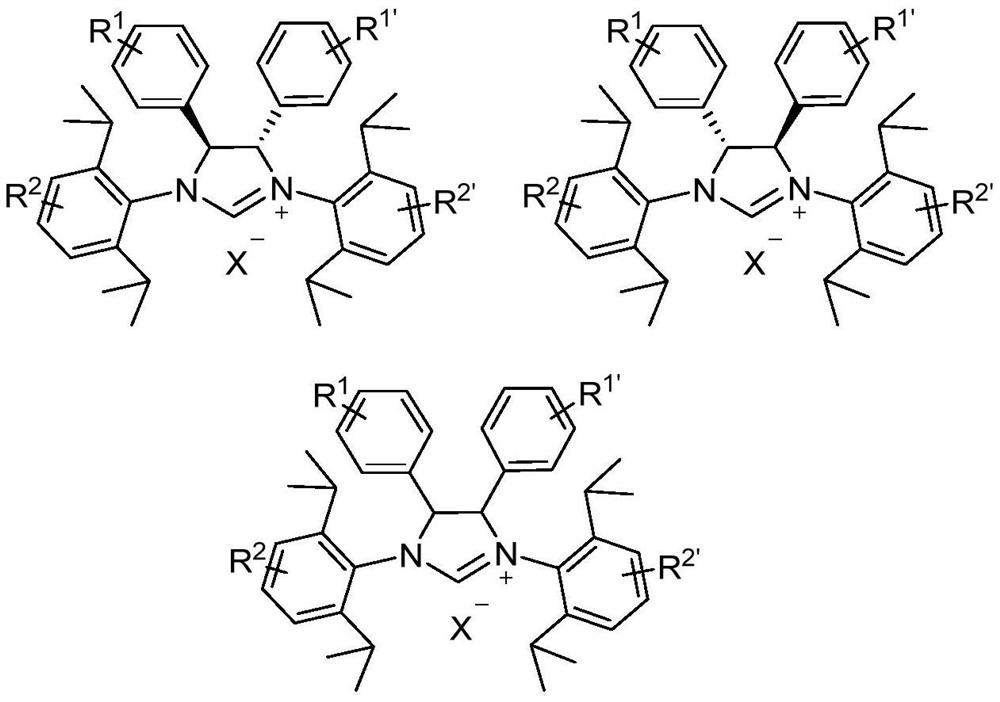

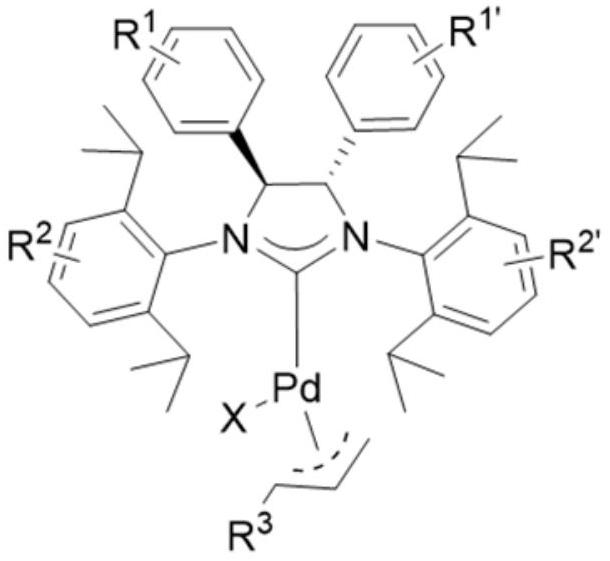

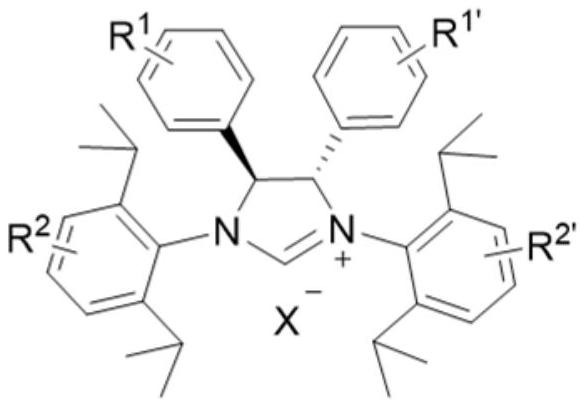

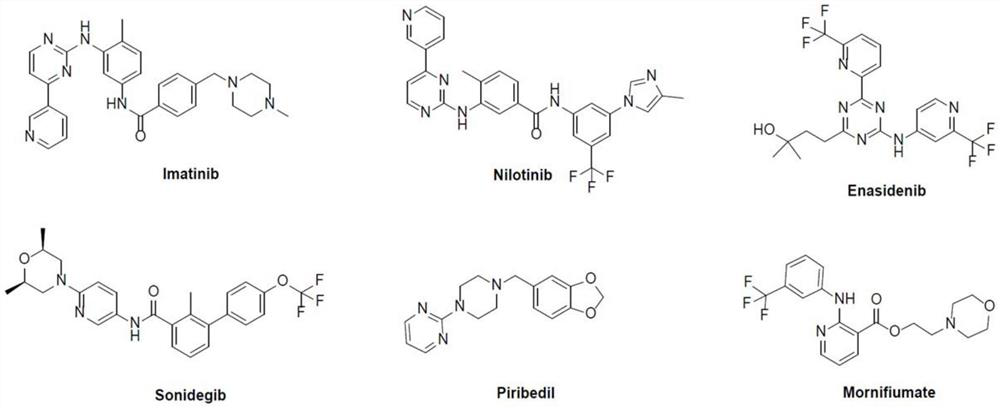

Large-steric-hindrance N-heterocyclic carbene palladium complex, preparation method and application thereof, and synthesis method of Sonidegib based on large-steric-hindrance N-heterocyclic carbene palladium complex

ActiveCN113788859AHigh catalytic activityImprove catalytic stabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsArylPtru catalyst

The invention belongs to the technical field of organic synthesis and chemical catalysis, and discloses a large-steric-hindrance N-heterocyclic carbene palladium complex, a preparation method thereof, application of the large-steric-hindrance N-heterocyclic carbene palladium complex to efficient catalysis of C-N coupling reaction at room temperature, and a synthesis method of Sonidegib based on the large-steric-hindrance N-heterocyclic carbene palladium complex. According to the structure of the large-steric-hindrance nitrogen heterocyclic carbene palladium complex, diphenyl imidazole serves as a main ligand framework, functionalized allyl serves as an auxiliary ligand, and the functionalized allyl is introduced beside a metal center of a catalyst to serve as the auxiliary ligand, so that the large-steric-hindrance nitrogen heterocyclic carbene palladium complex has remarkably improved catalytic activity and stability and can be applied to efficient catalysis of C-N coupling reaction; and especially, the catalyst can efficiently catalyze C-N coupling reaction at room temperature, and the yield can reach 99%. The invention also provides a three-step method for synthesizing the Sonidegib at room temperature by taking aryl / aliphatic amine and aryl chloride as reactants under the catalysis of a palladium catalytic system, the synthesis method provided by the invention has few steps, and the total yield can be up to 74.5%.

Owner:SUN YAT SEN UNIV

Nuclear fuel rod

ActiveUS20060050836A1Preventing secondary hydrogenationReduce riskFuel elementsNuclear energy generationInternal pressureAlloy

In a nuclear fuel rod a cladding tube is provided having a closed inner space and manufactured from at least one of the materials in the group zirconium and a zirconium-based alloy, and a pile of nuclear fuel pellets arranged in the inner space in the cladding tube. The nuclear fuel pellets fill part of the inner space. A fill gas is arranged in the closed inner space to fill the rest of the inner space. The internal pressure of the fill gas in the nuclear fuel rod amounts to at least 2 bar (abs) or at least 10 bar (abs). The fill gas contains a proportion of inert gas a proportion of carbon monoxide that is greater than 3 volume percent of the fill gas or greater than 2 volume percent of the fill gas.

Owner:WESTINGHOUSE ELECTRIC SWEDEN

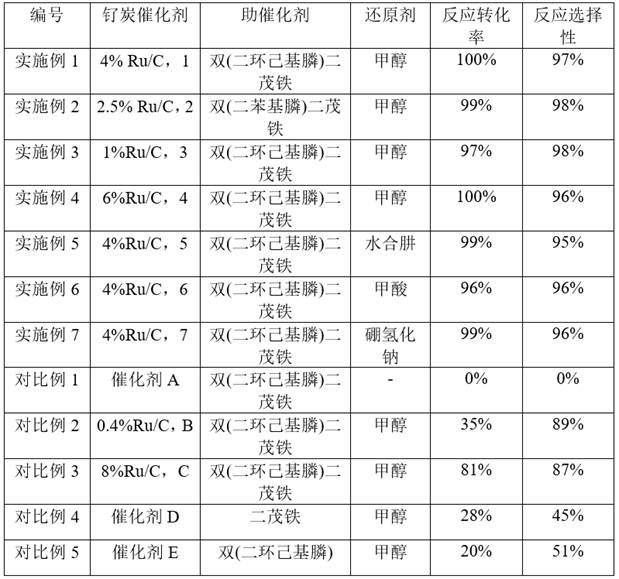

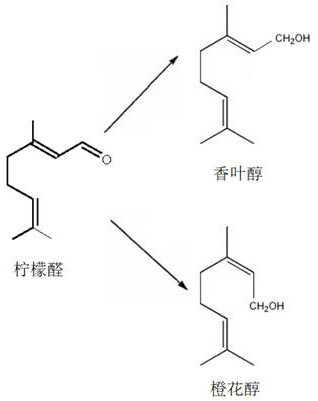

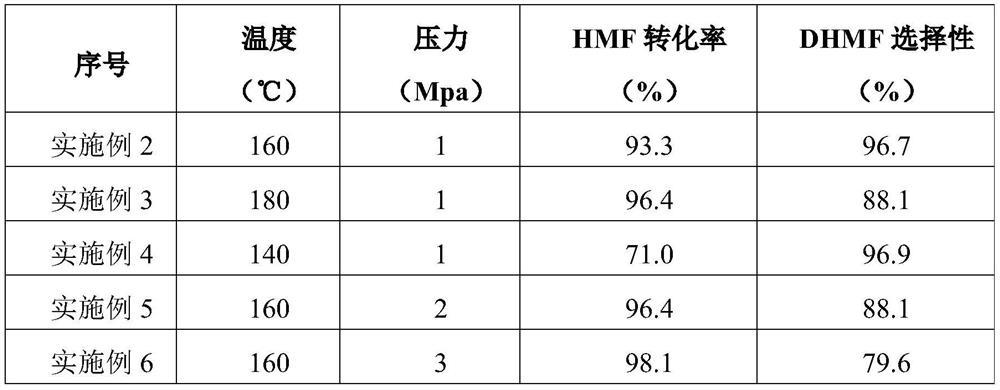

Ruthenium-carbon catalyst as well as preparation method and application thereof

ActiveCN113499771AImprove selectivity and reaction conversionHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCarbonyl groupActivated carbon

The invention relates to a ruthenium-carbon catalyst as well as a preparation method and application thereof. The ruthenium-carbon catalyst comprises an activated carbon carrier, ruthenium nanoparticles and a cocatalyst, the ruthenium nanoparticles and the cocatalyst are loaded on the activated carbon carrier, and the cocatalyst is a compound containing phosphorus and iron and capable of being coordinated with ruthenium ions; in the ruthenium-carbon catalyst, the mass content of the ruthenium nanoparticles is 1%-6%. According to the ruthenium-carbon catalyst, the activated carbon serves as a carrier, ruthenium nano-particles in a specific proportion are loaded, meanwhile, a phosphorus and iron containing compound capable of being coordinated with ruthenium ions is loaded to serve as a cocatalyst, the ruthenium-carbon catalyst can be used for catalyzing carbonyl selective hydrogenation, and then the selectivity and the reaction conversion rate of carbonyl selective hydrogenation are improved; for example, the catalyst is used for selective hydrogenation catalysis of carbonyl groups of unsaturated aldehydes to produce unsaturated alcohols. The ruthenium-carbon catalyst is used for selective hydrogenation of carbonyl of citral to prepare nerol and geraniol, the reaction conversion rate reaches 95%-100%, and the selectivity to nerol and geraniol reaches 90%-99%.

Owner:SUZHOU SINOCOMPOUND TECH

Large-steric-hindrance N-heterocyclic carbene palladium complex, preparation method and application thereof, and synthesis method of sonidegib based on large-steric-hindrance N-heterocyclic carbene palladium complex

InactiveCN112209972AC-N coupling efficiencyHigh catalytic activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSynthesis methodsOrganic synthesis

The invention belongs to the technical field of organic synthesis and chemical catalysis, and discloses a large-steric-hindrance N-heterocyclic carbene palladium complex, a preparation method thereof,an application of the complex in efficient catalysis of a C-N coupling reaction under a room-temperature air condition, and a synthesis method of sonidegib based on the complex. According to the large-steric-hindrance N-heterocyclic carbene palladium complex, diphenyl imidazole serves as a main ligand framework, functionalized allyl serves as an auxiliary ligand, the functionalized allyl is introduced beside a metal center of a catalyst to serve as an auxiliary ligand, the catalytic activity and stability are remarkably improved, the large-steric-hindrance N-heterocyclic carbene palladium complex can be applied to efficient catalysis of a CN coupling reaction, particularly, the CN coupling reaction can be efficiently catalyzed under the room temperature condition, and the yield can reachup to 99%. The invention also provides a method for synthesizing sonidegib by taking aryl / aliphatic amine and aryl chloride as reactants and a three-step method at room temperature under the catalysisof a palladium catalytic system, the synthetic method has few steps, and the total yield can reach 74.5%.

Owner:SUN YAT SEN UNIV

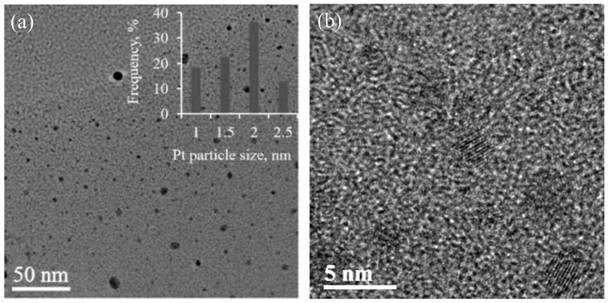

Preparation method and application of Pt nanoparticle-loaded biochar catalyst

ActiveCN112275282ANo edible valueLow priceOrganic chemistryCatalyst activation/preparationPtru catalystNanoparticle

The invention relates to a preparation method and application of a Pt nanoparticle-loaded biochar catalyst, and belongs to the technical field of catalysts. According to the catalyst, biochar is takenas a carrier, and Pt nanoparticles are loaded; Pt nanoparticles are used as active sites, the loading capacity of the Pt nanoparticles is 1-10wt.%, and the particle size of the Pt nanoparticles is 1-3nm. The carrier and the Pt nanoparticles are combined through an impregnation method, the operation is simple, the cost is low, the Pt nanoparticles are uniformly distributed on the carrier, the sizeof the Pt nanoparticles is small, and the utilization rate is higher.

Owner:DALIAN MARITIME UNIVERSITY

Process for preparing a novel synergistic solid/semi-solid organic composition

InactiveUS6391928B1Improve the coagulation effectSimple and cost-effectiveOther chemical processesFatty-oils/fats/waxes solidificationLong chain fatty acidAdditive ingredient

This invention relates to a novel synergistic reversible solid / semi-solid organic composition, said composition comprising (a) at least one saturated long chain fatty acid and / or its glycerol esters and (b) one or more liquid neutral organic compounds, said ingredients (a) and (b) being present in a ratio between 0.1 to 40% by weight, and a process for producing said synergistic reversible solid / semi-solid organic composition by mixing the ingredients (a) and (b) defmed above in a ratio between 0.1 to 40% by weight, at a temperature between 2 to 50° C. and at a pressure in the range of 200 torr to 2500 torr.

Owner:INDIAN INSTITUTE OF SCIENCE +1

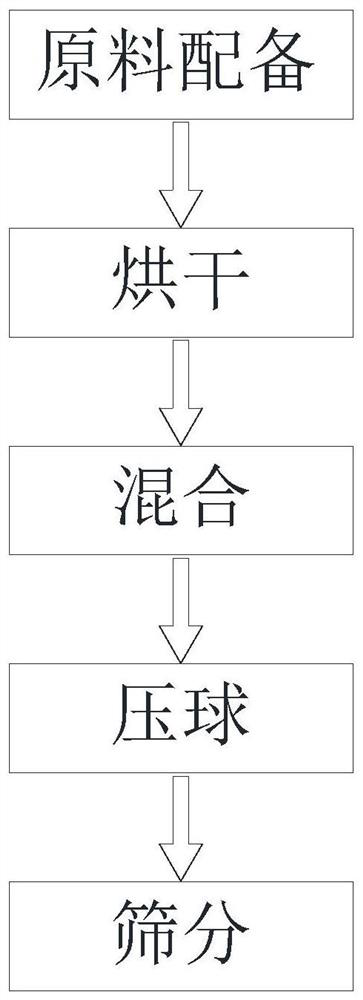

Preparation method of aluminum-calcium multifunctional slag washing material

The invention discloses a preparation method of an aluminum-calcium multifunctional slag washing material, and belongs to the technical field of steel smelting. The preparation method of the aluminum-calcium multifunctional slag washing material comprises the following steps: S1, preparing raw materials; S2, drying; and S3, mixing. In the step S1, the raw materials comprises, by mass, 5%-20% of Al, 10%-40% of Al2O3, 30%-50% of CaO and 5%-20% of an additive; in the step S2, the CaO is put into a drying box and dried; and in the step S3, the Al and the Al2O3 are crushed until the particle size is less than 5mm, the CaO is crushed until the particle size is less than 60mm, and the additive is added for mixing. According to the preparation method, finished products and the raw materials do not contain polluting elements, so that the safety and the environmental protection property are remarkable; and a high-temperature melting environment is not needed in the preparation process, so that the energy digestion is reduced, and safety is further improved.

Owner:ZHENGZHOU DONGSHENG METALLURGY NEW MATERIAL

A kind of slag system for electroslag remelting

The invention discloses a slag system for electroslag remelting, which belongs to the technical field of electroslag metallurgy. The composition and mass percentage of the slag system for electroslag remelting are: CaF2: 50-60%, CaO: 5-20%, SiO2 : 20-35%, Al2O3: 5-15%, and the rest are unavoidable impurities. Compared with the conventional slag material, the material of the present invention reduces the content of CaO and Al2O3, increases the percentage content of SiO2, and has low air permeability of the slag, which is beneficial to prevent hydrogenation, especially in the humid rainy season. The slag composition is conducive to keeping the slag resistance constant, and the melting point is low, and the power consumption is reduced during remelting. Deformable silicate-type inclusions with small size, thus improving the fatigue properties of the steel.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

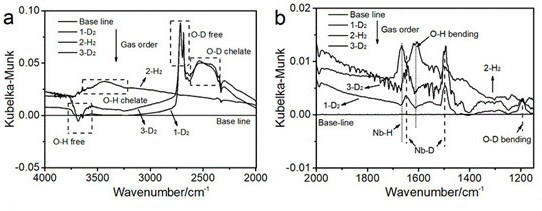

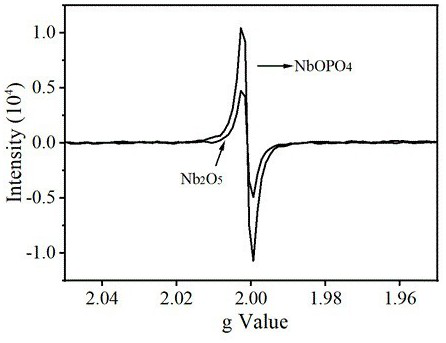

Hydrocracking aromatic polymer and method for preparing aromatic hydrocarbon from heavy aromatic hydrocarbon

ActiveCN114410343AHigh molar yieldAvoid hydrogenationLiquid hydrocarbon mixture productionHydrocarbon oil crackingPtru catalystPorous carbon

The invention provides a metal-site-free method for preparing aromatic hydrocarbon by hydrocracking aromatic polymer and heavy aromatic hydrocarbon by dissociating hydrogen through an oxide, which comprises the following steps of: reacting the aromatic polymer with a catalyst in the presence of hydrogen at the temperature of below 350 DEG C; and rectifying and separating reaction products to obtain aromatic hydrocarbons. The catalyst contains at least one of niobium oxide, niobium phosphate, a niobium-silicon mixed oxide, a niobium-aluminum mixed oxide and a porous carbon-niobium material.

Owner:EAST CHINA UNIV OF SCI & TECH

A production method of pre-melted slag for small-batch electroslag remelting

ActiveCN108034834BRealize the production of premelted slag for remeltingAchieve productionCrusherMolten slag

The invention discloses a production method for pre-melted slag for small-batch electroslag remelting. The production method comprises the steps that firstly, a slag melting bag with the volume being300 kg is selected and used; secondly, pre-melted slag raw materials are taken to be preheated and baked in a slag baking furnace; thirdly, the baked pre-melted slag raw materials with the weight being smaller than or equal to 300 kg in the second step are placed in the slag melting bag in the first step, a double-pole series connection electroslag furnace is used for arc strike for slag melting in the slag melting bag, and after slag melting is over, the slag liquid is poured into a steel tank to be cooled and solidified; and fourthly, slag blocks solidified in the third step are crushed through a small crusher, and the slag blocks serve as pre-melted slag for electroslag remelting after being weighed. The double-pole series connection electroslag furnace is utilized for slag melting in the slag melting bag, production of small-batch pre-melted slag with the weight being smaller than or equal to 300 kg is achieved, and the problem that pre-melted slag for the small-batch test steel grade is hard to produce and purchase is solved. The method is simple, convenient to use and worthy of popularization and application.

Owner:XINGTAI IRON & STEEL

A method for alleviating stress corrosion of primary circuit structure materials of PWR

ActiveCN104593778BStress corrosion mitigationImprove stress corrosion resistancePressurized water reactorPhysical chemistry

The invention belongs to the technical field of reactor engineering stress corrosion, and discloses a method for alleviating stress corrosion of a pressurized-water-reactor primary-loop structure material. The method comprises adding a noble metal salt solution into a coolant of a pressurized-water-reactor primary loop, wherein the concentration scope of the noble metal salt solution in the coolant is 10-1000 mu g / Kg, the injection amount is 1-100 mu g / day, and the noble metal salt solution is a salt solution of one or a mixture of Pt and Rh. The method possesses the advantages of being capable of alleviating the electrochemical corrosion potential at the surface of the pressurized-water-reactor primary-loop structure material, improving the stress corrosion resistance of the structure material and prolonging the service life of the structure material.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com