Preparation method of aluminum-calcium multifunctional slag washing material

A multi-functional, aluminum-calcium technology, applied in the field of iron and steel smelting, can solve the problems of reducing the service life of equipment, short effective time, increasing production costs, etc., to achieve the effect of ensuring the use effect, good reducibility, and reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

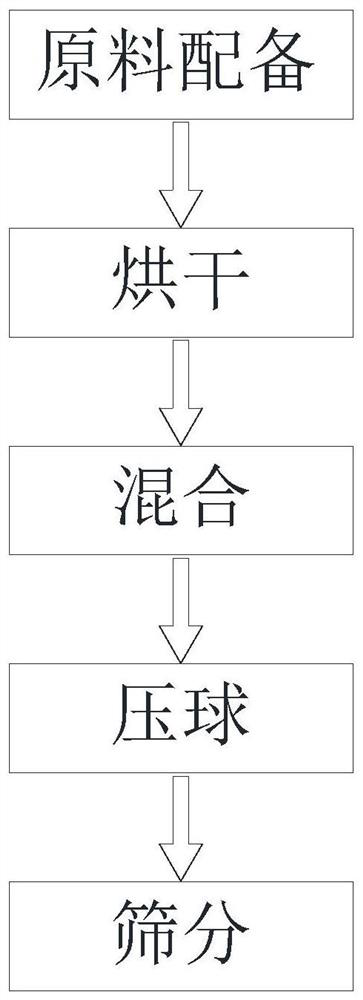

[0029] see figure 1 , a method for preparing aluminum-calcium multifunctional slag washing material, comprising the following steps:

[0030] S1, raw material preparation: prepare raw materials according to the following mass fractions, 5% to 20% Al, 10% to 40% Al 2 o 3 , 30% to 50% of CaO, 5% to 20% of additives.

[0031] Among them, the additives consist of MgO and SiO 2 composition. Preferably, the additive consists of 40% to 60% of MgO and 40% to 60% of SiO 2 composition.

[0032] MgO improves impurity removal effect, SiO 2 Promote melting, facilitate slag formation in advance, and further improve product performance.

[0033] S2, drying: put the CaO into a drying box for drying.

[0034] When the slagging material is not dry, it is easy to add hydrogen to the molten steel; because of its easy water absorption, CaO is dried before processing to remove the residual water in it, reduce the water absorption rate, keep it dry, and ensure the use effect.

[0035] Prefe...

Embodiment 2

[0041] As a preferred solution, the difference from Example 1 is that in step S1 raw material allocation, the raw materials are prepared according to the following mass fractions, 20% Al, 15% Al 2 o 3 , 50% CaO, 8% MgO, 7% SiO 2 .

Embodiment 3

[0043] As a preferred solution, the difference from Example 1 is that in step S1 raw material allocation, the raw materials are prepared according to the following mass fractions, 15% Al, 30% Al 2 o 3 , 45% CaO, 5% MgO, 5% SiO 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com