Ruthenium-carbon catalyst as well as preparation method and application thereof

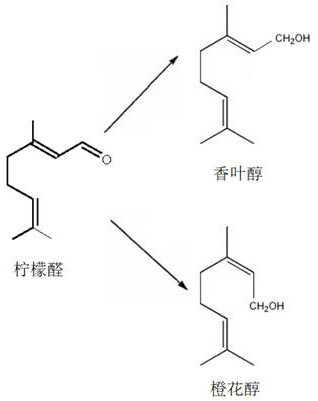

A technology of ruthenium carbon catalyst and co-catalyst, which is applied in the field of ruthenium carbon catalyst and its preparation, can solve problems such as difficulty in obtaining nerol or geraniol, and achieve the effect of improving selectivity and reaction conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

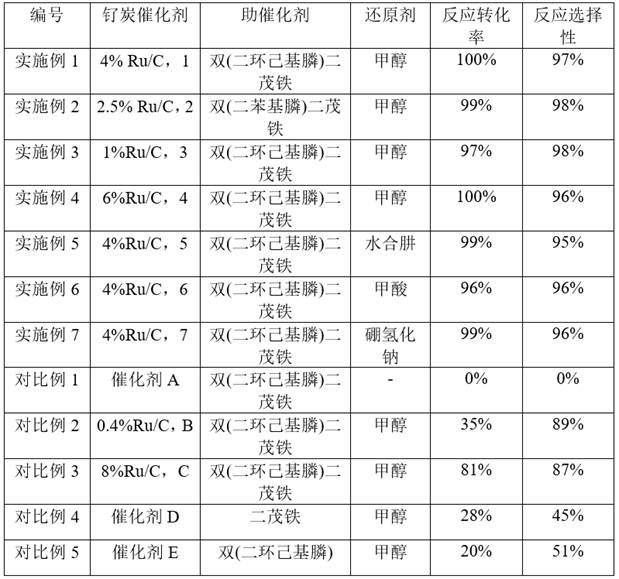

Examples

preparation example Construction

[0037] One embodiment of the present invention provides the preparation method of above-mentioned any one ruthenium carbon catalyst, comprises following steps S10~S20:

[0038] Step S10: soak the activated carbon carrier in a reducing solvent and take it out.

[0039] Step S20: adding the activated carbon carrier to the precursor solution containing ruthenium ions and co-catalysts, impregnating, and drying to obtain a ruthenium carbon catalyst; the co-catalyst is a compound containing phosphorus and iron that can coordinate with ruthenium ions; the ruthenium carbon catalyst includes activated carbon Carrier and ruthenium nanoparticles and promoters loaded on the activated carbon carrier; in the ruthenium carbon catalyst, the mass content of ruthenium nanoparticles is 1%~6%.

[0040] The preparation method of the above-mentioned ruthenium carbon catalyst, by soaking the activated carbon carrier in a reducing solvent or a solution containing a reducing agent, the activated carbo...

Embodiment 1

[0067] After soaking 90 grams of activated carbon carrier in 1000 grams of methanol for 8 hours, it was dried at 20° C., and two (dicyclohexylphosphine) ferrocene ruthenium chloride solutions containing 5 grams of ruthenium were added to the activated carbon carrier at 70° C., 120 ℃ drying to generate ruthenium carbon catalyst, which is counted as 4%Ru / C catalyst 1; where 4% refers to the mass content of ruthenium nanoparticles in the ruthenium carbon catalyst, the same below.

Embodiment 2

[0069] After soaking 94 gram gac carriers in 1000 gram methanol for 8 hours, dry at 20 DEG C, the bis(diphenylphosphine) ferrocene ruthenium chloride solution containing 3 gram ruthenium is added in gac carrier at 80 DEG C, 110 ℃ drying to produce 2.5%Ru / C catalyst 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com