Catalyst system for preparing cyclohexene by benzene selective hydrogenation, and method for preparing cyclohexene by benzene selective hydrogenation by catalyzing with catalyst system

A technology for selective hydrogenation and catalytic system, applied in the chemical industry, can solve the problems of low selectivity and yield of cyclohexene, unsatisfactory application effect, general yield comprehensive effect, etc., and achieve the effect of high selectivity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Nano metal Ru catalyst preparation:

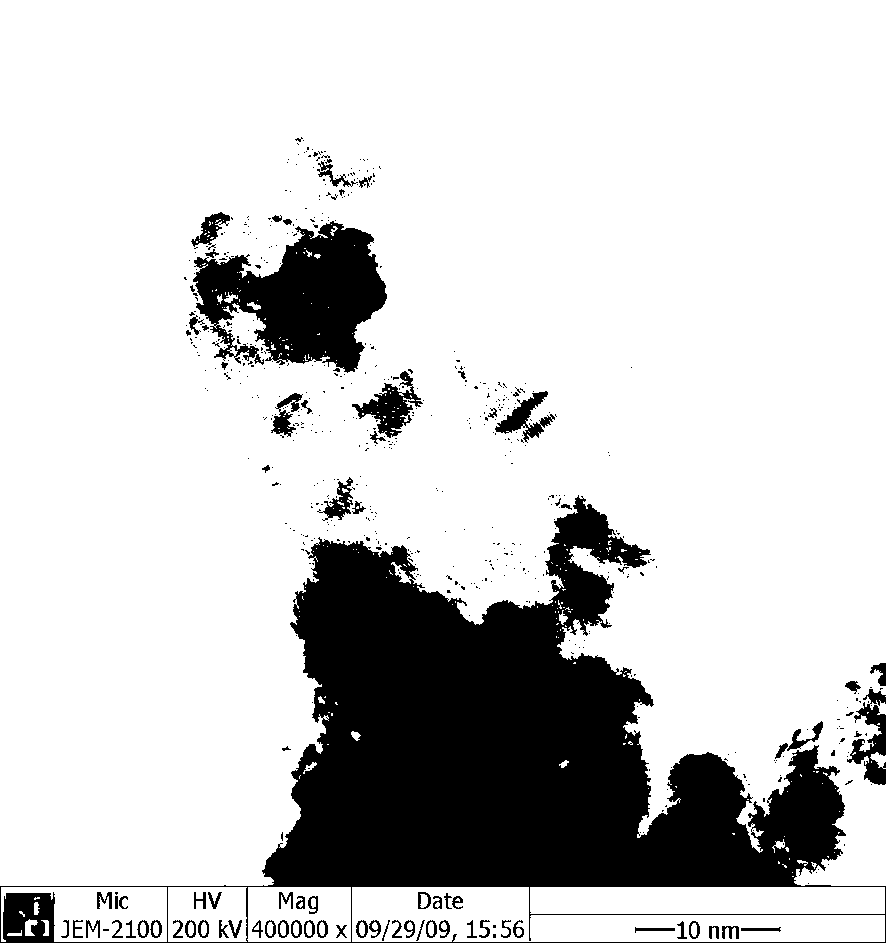

[0030] Prepared by co-current precipitation method. At 70 °C, RuCl 3 The solution is one side, the concentration is 0.4 M, and the volume is 400 ml; the NaOH and polyethylene glycol solution is the other side, the concentration is 2 M, which contains 1.6 g polyethylene glycol-10000. Controlling the same flow rate, the two solutions are mixed and then enter into a stirred reactor, where the reaction takes place under sufficient stirring. After the reaction was complete, the mixture was stirred for 30 min and cooled to room temperature. The reaction mixture was transferred to a 1 L Teflon-lined autoclave. At a stirring rate of 800-1200 r / min, at 150°C, 5 MPa H 2 Press down and restore for 3 h. Cool to room temperature, introduce the liquid in the kettle into the settling tank, and remove the supernatant. The obtained black solid Ru catalyst was washed with distilled water until neutral, and dried in vacuum. Utilize TEM to measu...

Embodiment 2

[0033] Take 2 g of the nano-Ru catalyst in Example 1, add 0.32 g of NaOH, and other conditions are the same as in Example 1. The catalyst evaluation results are listed in Table 1.

Embodiment 3

[0035] Take 2 g of the nano-Ru catalyst in Example 1, add 5.70 g of NaOH, and other conditions are the same as in Example 1. The catalyst evaluation results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com