Blended yarn with health care and flame retardant functions and spinning method thereof

A blended yarn and functional technology, applied in the field of blended yarn and its spinning, can solve the problems of no flame retardancy, fire, etc., and achieve the effects of good wear resistance, good moisture absorption, and high elastic flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Cross-sectional shape of fibers

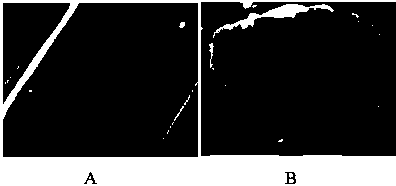

[0032] Observations were performed with a Sigma 500 field emission scanning electron microscope. Such as figure 1 As shown, the longitudinal section of the bamboo dale fiber is smooth, with grooves, and the cross section has holes, and the hygroscopicity of the fiber is relatively good; as figure 2 As shown, there are grooves in the longitudinal section of nylon fiber, and the cross section is round or shaped; such as image 3 As shown, the longitudinal appearance of the flame-retardant acrylic fiber shows that the fiber surface is smooth, with shallow grooves and stripes, and the cross-section is near-sighted and round.

Embodiment 2

[0033] Example 2: Bamboo dale / nylon / flame retardant acrylic blended yarn

[0034] Select slivers to mix, 6 to mix and merge. Design the textiles with the blending ratio of bamboo dal, nylon and flame-retardant acrylic fiber as 20 / 50 / 30, 35 / 35 / 30, and 50 / 20 / 30, and design the linear density of the blended yarn as 21tex.

Embodiment 3

[0035] Embodiment 3: the technological process of spinning

[0036] Since the three kinds of fibers are all chemical fibers, there are relatively few impurities, the fiber length is long, and the uniformity is good. Static electricity is easily generated during the production process. Excessive blows should be avoided to reduce damage to the fibers and reduce the speed. In general, the principles of diligent grasping, combing instead of beating, more loosening and less beating, more recovery, less elimination, and full mixing are adopted.

[0037] (1) Bamboodale fiber FA002C plucking machine→FA022 multi-compartment blending machine→FA006A comb roller opener→A092AST double cotton box feeder→FA141 single hand lapping machine→FA201 carding machine→FA306 pre-merger strip;

[0038] (2) Nylon fiber FA002C grabbing machine → FA022 multi-compartment blending machine → FA006A comb roller opener → A092AST double cotton box feeder → FA141 single hand lapping machine → FA201 carding mach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| twist factor | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com