Split-type ten-cylinder reciprocating pump

A split-type, reciprocating pump technology, applied in the field of reciprocating pumps, can solve the problems of poor suction and discharge performance and reliability of reciprocating pumps, reciprocating pump cut-off sedimentation flow, large pressure fluctuations, etc., to reduce the problem of cut-off sedimentation and vibration , Improve the effect of uneven load and reduced alternating load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

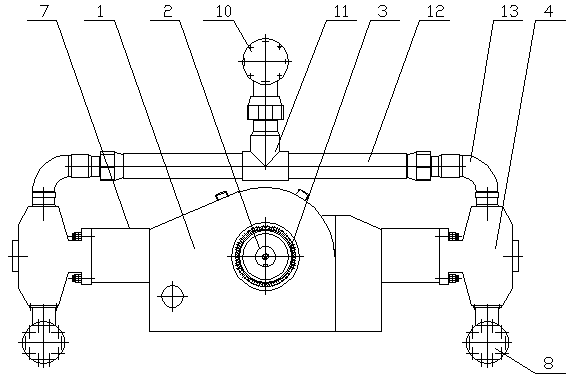

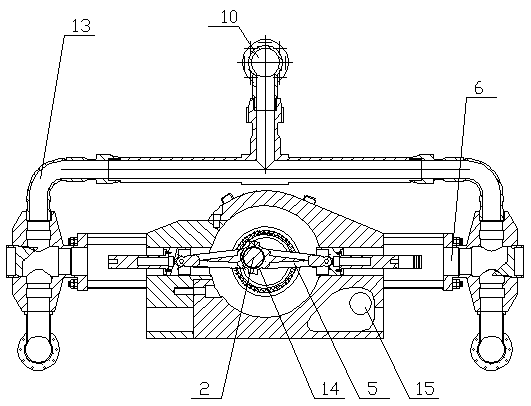

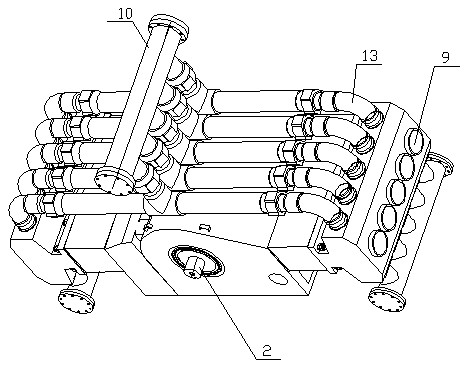

[0028] The split-type ten-cylinder reciprocating pump is composed of a housing 1, a crankshaft 2, a cylindrical bearing 3, a fluid end assembly 4, a connecting rod 5 and an intermediate rod 6, the housing 1 is provided with a housing upper cover, and the housing 1 The fluid end assembly 4 is installed on both sides through the dustproof shell 7, and an assembly hole 9 is arranged on the outer end surface of the fluid end assembly 4; The fluid end assembly 4 is connected. A discharge main pipe 10 is arranged above the upper cover of the housing, and the discharge main pipe 10 communicates with the fluid end assembly 4 through a T-shaped tee pipe 11 , a connecting pipe 12 and an elbow 13 .

[0029] A crankshaft 2 is installed in the casing 1 of the split-type ten-cylinder reciprocating pump through a cylindrical bearing 3, and five crankshafts are arranged on the crankshaft 2. The five crankshafts are arranged on the crankshaft 2 according to #1, #2, #3, # 4. The order of #5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com