Buried pipe casting water cooling fire grate segment

A technology for water-cooled grate and grate sheet, applied in the field of incineration, can solve the problems affecting the operating cost and economic benefit of a domestic waste incineration plant, the grate sheet does not have a water-cooling function, and the frequency of replacement of the grate sheet is increased, so as to reduce flue gas emissions. the cooling effect is uniform, and the effect of reducing the operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

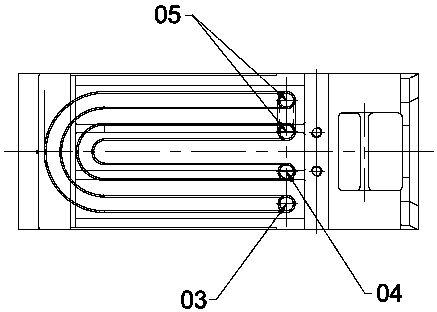

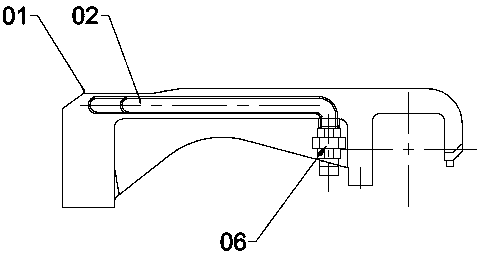

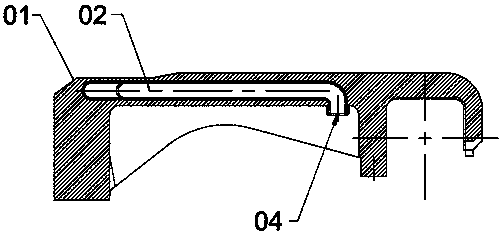

[0020] Such as figure 1 , figure 2 with image 3 As shown, the water-cooled grate body 1 is cast, and the cooling water pipe 2 is included in the water-cooled grate 1 during the casting process. There is an extension of the cooling water pipe at the bottom of the grate, and the water inlet joint 3, the water outlet joint 4 and through The stainless steel connecting pipe 6 is responsible for connecting the two connecting joints 5 of the double U-shaped cooling water pipes. During operation, water is supplied by the circulating cooling water system, and the external water pipe is connected to the water inlet joint 3 and the water outlet joint 4. At the same time, the stainless steel connecting pipe 6 is connected to the interface 5. The water flows in from the water inlet and flows into the cooling water pipe in the grate. The large U-shaped pipe flows into the smaller U-shaped pipe through the connection interface 5 and the stainless steel connecting pipe 6, and finally flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com